Lean Manufacturing

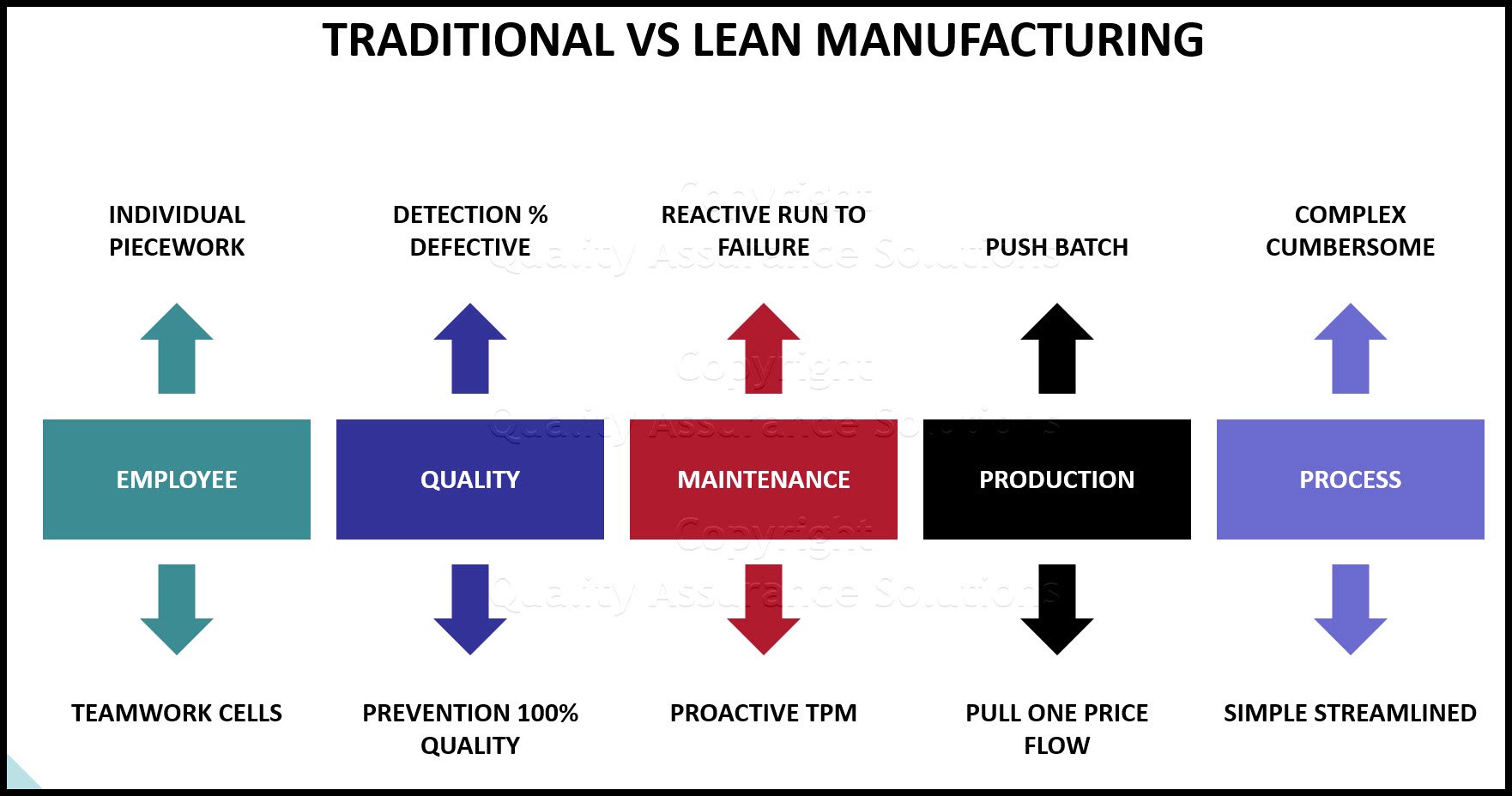

Lean manufacturing is a generic process management philosophy derived mostly from the Toyota Production System (TPS) but also from other sources. Toyota's steady growth from a small player to the most valuable and the biggest car company in the world made Lean a hot topic in management science. In order to improve overall customer value, the Lean approach focuses on the reduction of the original Toyota 8 wastes.

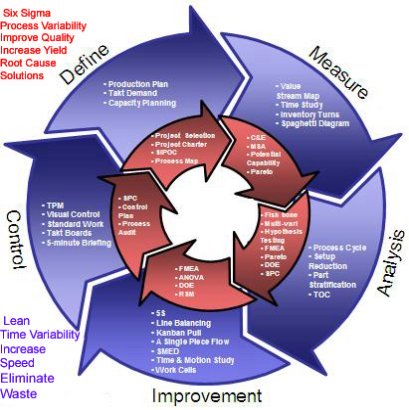

Lean and DMAIC picture above from Lean Sigma Institute

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Five Principles Of Lean Manufacturing:

Principle 1: Accurately specify the value from the customer's perspective for both products and services.

Principle 2: Identify the value stream for products and services and remove any non-value-added waste along the value stream.

Principle 3: Make the product and services flow without interruption across the value stream.

Principle 4: Authorize production of products and services based on the pull from the customer.

Principle 5: Strive for perfection by constantly removing layers of waste.

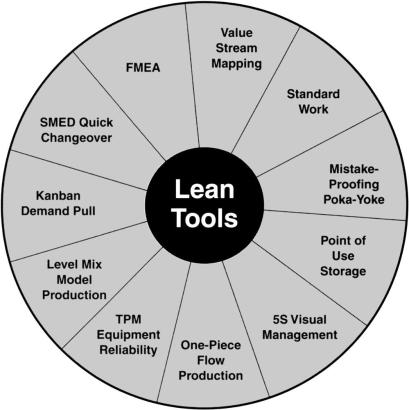

Lean Tools

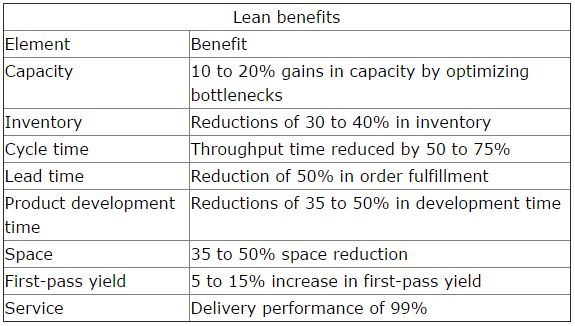

Lean is the set of 'tools' that assist in the identification and steady elimination of waste (muda), the improvement of quality, and production time and cost reduction. Below is a picture and links to some of the common Lean Tools.

Overall Equipment Effectiveness

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Another Lean Approach

There is a second approach to Lean Manufacturing that is promoted by Toyota. This focuses's upon implementing the smoothing the flow (opposite of mura, unevenness) through the system and not upon 'waste reduction'. Techniques to improve flow include production leveling, pull production (by means of kanban) and the Heijunka box.

Standard Work

Standard work means there is a set of work procedures that effectively combine people, materials, processes, technology, and machines to maintain quality, efficiency, safety, and predictability.

It establishes the best methods and sequence steps to optimize performance and minimize waste. After creating the work procedures you train people to follow the established standard.

This help ensures employees complete a process the same way every time no matter who works the tasks. High quality is a direct output of a repeatable process.

Applying this throughout the enterprise gains consistency in manufacturing processes. In addition there is a wealth of opportunities for applying standardized work to administrative processes. This tool is not just a lean tool for manufacturing but necessary for Quality Systems certifications such as ISO 9001.

Be sure to integrate the lean tool of 5S-visual-management, Quick-Changeover, and Mistake-proofing when writing work procedures.

By Applying Standard Work, You...

- Create repeatable processes.

- Identify the most efficient method for a process.

- Implement defective and productive training for employees.

- Establish documentation for each process.

- Improve process and product quality.

- Lower cost associated with scrap and rework.

- Reduces excessive processing due to poor process design.

- Eliminate excessive and unnecessary motion for a process.

- Identify waste in a process.

- QAS Home

- Lean MFG

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |