7 Wastes of Lean

Sharpen your competitive edge by eliminating the 7 wastes of lean in your organization.

Recession or boom, companies need to sharpen their competitive edge by applying Lean Management principles to cost reduction by eliminating the non-value-added activities or waste from the value stream processes.

Be Lean

In the Lean Management philosophy, we group all activities in the organization into two categories:

- value-added (VA) activities

- non-value-added (NVA) activities.

In the context of Lean Management, we view VA and NVA activities from the customer perspective.

VA activities bring higher value to products and services. Examples include

- answering customer queries

- entering orders

- ordering materials

- laying foundation

- creating codes

- assembling parts

- shipping of goods to customers.

Customers are willing to pay for these improvements which can change the form, fit or function of a product or service.

On the other hand, NVA tasks do not increase market form or function.

Examples of Non Value Added activities include

- filing

- copying

- recording

- waiting

- counting

- checking

- inspecting

- testing

- reviewing

- obtaining approvals

You need to eliminate, simplify or reducing the 7 wastes of lean in production as much as possible. By tackling waste from an end-to-end business process you

- improve the value of your products and services

- achieve significant cost reduction

- strengthen cash flow

- emerge from a downturn with a stronger and more competitive profile.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

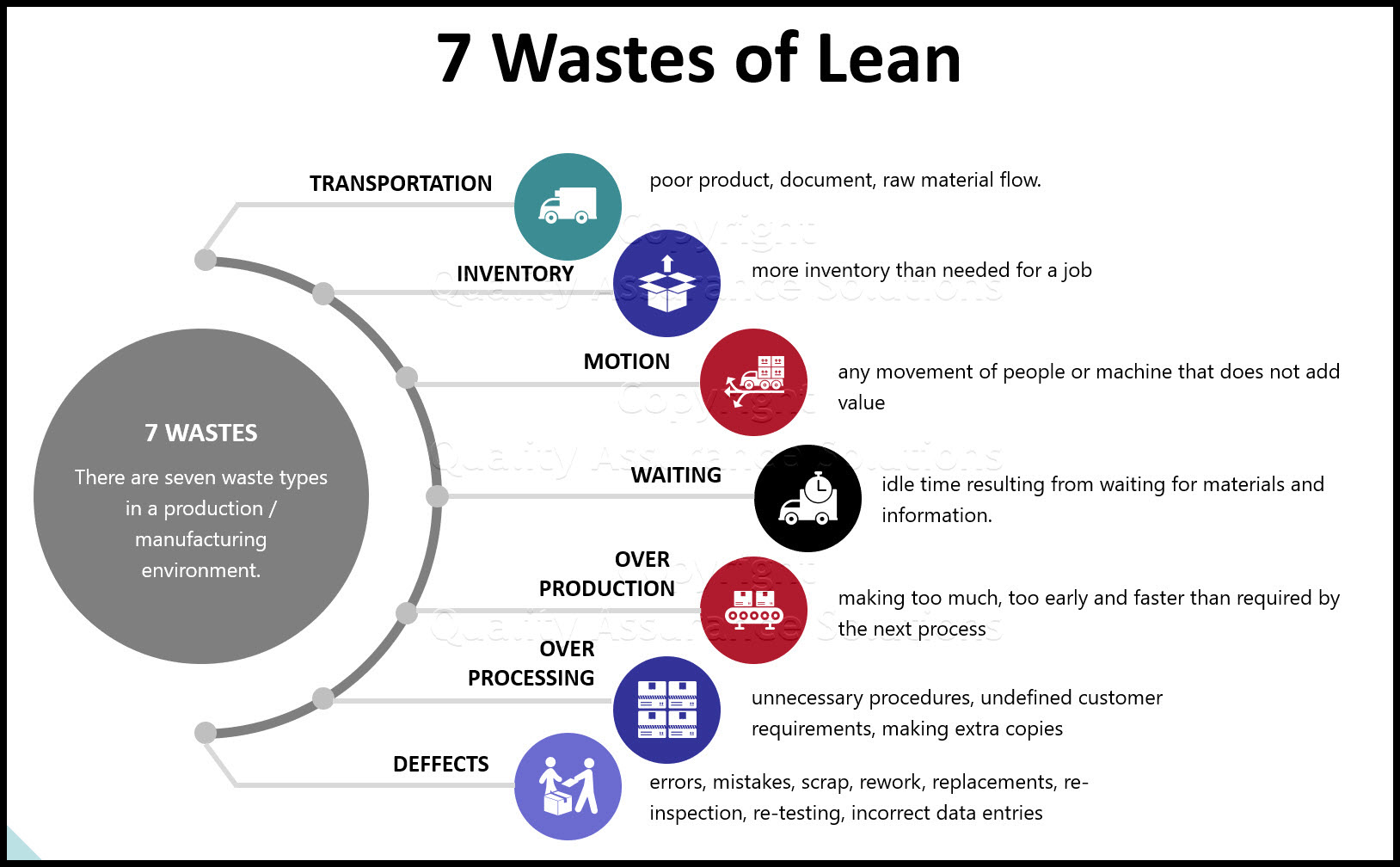

7 Wastes of Lean

There are seven waste types in a production / manufacturing environment.

Studies have shown that in a typical organization, some 90% or more of all activities fall into the NVA bucket.

Although the explanations and examples provided below may be more relevant for manufacturing industries, the concepts can be universally applied to service industries as well.

The 7 manufacturing wastes are:

1) Waiting.

- idle time resulting from waiting for materials and information

- email queues from customers

- delayed shipments

- lot processing delays

- capacity bottlenecks

- unbalanced workload

- long setup times equipment

- system downtime

2) Over-Processing

- unnecessary procedures

- undefined customer requirements

- lack of effective communication

- product changes without process changes

- redundant approvals

- making extra copies

- excessive reporting.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

3) Defects

- errors

- mistakes

- scrap

- rework

- replacements

- re-inspection

- re-testing

- incorrect data entries

- poor quality

- weak process control

- inadequate training

- deficient planned maintenance

- customer needs that were not understood.

4) Excess Motion

- any movement of people or machine that does not add value.

- poor plant or office layout

- double handling

- inconsistent work methods

- poor workplace organization

5) Transportation

- poor product flow

- poor document flow

- poor raw material flow.

- poor plant or office layout

- widely spaced equipment and workstations

- poor understanding of the process flow.

6) Over-Production

- making too much, too early and faster than required by the next process.

- unclear goals

- excessive lead times

- outdated forecasts.

- large batch sizes

- producing greater than customer demand.

7) Excess Inventory

- more inventory than needed for a job.

- large orders of raw material.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Eliminate the Waste

The ability to find waste in your organization is the first step towards their elimination.

For the next step set up a problem solving teams and enable them to reduce or eliminate the waste. Use the common problem solving technique of PDCA (Plan-Do-Check-Act).

Involve your employees in problem solving or process improvement. They can identify sources of waste or savings that you might not be aware of.

Do note that not all waste equate the same. You need to identify the “right waste”– those that have the greatest impact on the business case or bottom line.

Continuous Process

For waste elimination to be successful and sustainable, an organization’s senior executives need to adopt a mindset that cutting waste to cut costs creates an on-going journey of continuous improvement.

management and employees must collaborate for successful removal of the 7 wastes of lean.

Senior executives need to avoid treating waste elimination as another one-off “tool” or quick fix.

Essential to managing waste elimination, you must align this strategic change initiative to the organization’s purpose, encompassing both people and process transformations.

Article written by Allan Ung of Operation Excellence Consulting for Quality Assurance Solutions. Article edited and posted by Quality Assurance Solutions

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |