Tool Calibration

and

Control System

The Tool Calibration and Control System is an overarching system within your Quality Assurance Management Systems. It is required for ISO 9001 registration. Ensuring your measurement instruments are measuring correctly is important to maintaining your process and product quality. Calibration is the process of comparing an instrument's accuracy to known standards. The instrument accuracy is usually documented in the equipment’s manual.

When calibrating the equipment, compare across the entire measurement range of the equipment. Select accuracy data points from the low, mid and high range of the equipment.

The known standard must have a tighter accuracy then the instrument. For calibration of dimensional tools, the known standard should have a 10 to 1 accuracy of the instrument.

Includes an easy to edit Calibration Manual, recommended calibration system, reports and templates.

Calibration Standards

There are 3 types of standards in your tool calibration and control system:

Primary Standards: Those units or instruments of highest quality and stability which are periodically calibrated by the National Institute of Standards and Technology (NIST) or by other contract calibration services which have direct traceability to NIST. Primary standards are used in a controlled environment of 23°C ±2°C and relative humidity of 40% ±10% (when applicable).

Transfer Standards: Those units or instruments with proven stability are calibrated from primary standards in a controlled environment. Transfer standards are stored in a controlled environment of 23°C ± 2°C and relative humidity of 40% ±10% (when applicable).

Working Standards: Those units or instruments with proven stability that are calibrated from transfer standards.

You use working standards to measure product and process quality. Transfer standards are used to calibrate the working standards. These are traceable to NIST. Primary standards are usually kept at NIST or calibration labs and maintain NIST certification. All standards must be traceable to NIST.

What instruments needs calibration?

- Working, Primary and Transfer Standards

- Any tool that is used to measure product quality

- Any measurement equipment that is used to monitor and measure the process, process inputs or process outputs

We recommend reviewing all process equipment that have continuous analog or digital output. If there are no other calibrated instruments that can be used to monitor that output, then that process equipment also needs to be calibrated.

For example, an oven has a digital readout. Lets say the oven needs to be set at 125 C. During oven operation the digital readout is 125 C, but how can you be sure this is correct? If you have a calibrated thermometer then this can be used assure the oven is actually 125 C. If you do not have a calibrated thermometer then the oven’s digital readout needs to be calibrated.

Includes an easy to edit Calibration Manual, recommended calibration system, reports and templates.

Tool Calibration and Control Documentation Elements

- Master list of the calibrated tools

- The flow of the recall process

- The method of determining recall period

- Determine the calibration procedure for each type of instrument. See here for an example

- Determine the calibration records that shows the requirements and calibration results.

- Discuss the flow to assure that new instruments / process equipment are calibrated prior to use.

- Cover the actions taken when the instrument is found out of calibration

- Present your company’s calibration labels which shows calibration status

- Cover the use, handling and storage of standards

- Determine the identification of defective standards.

- Discuss the process of handling lost standards

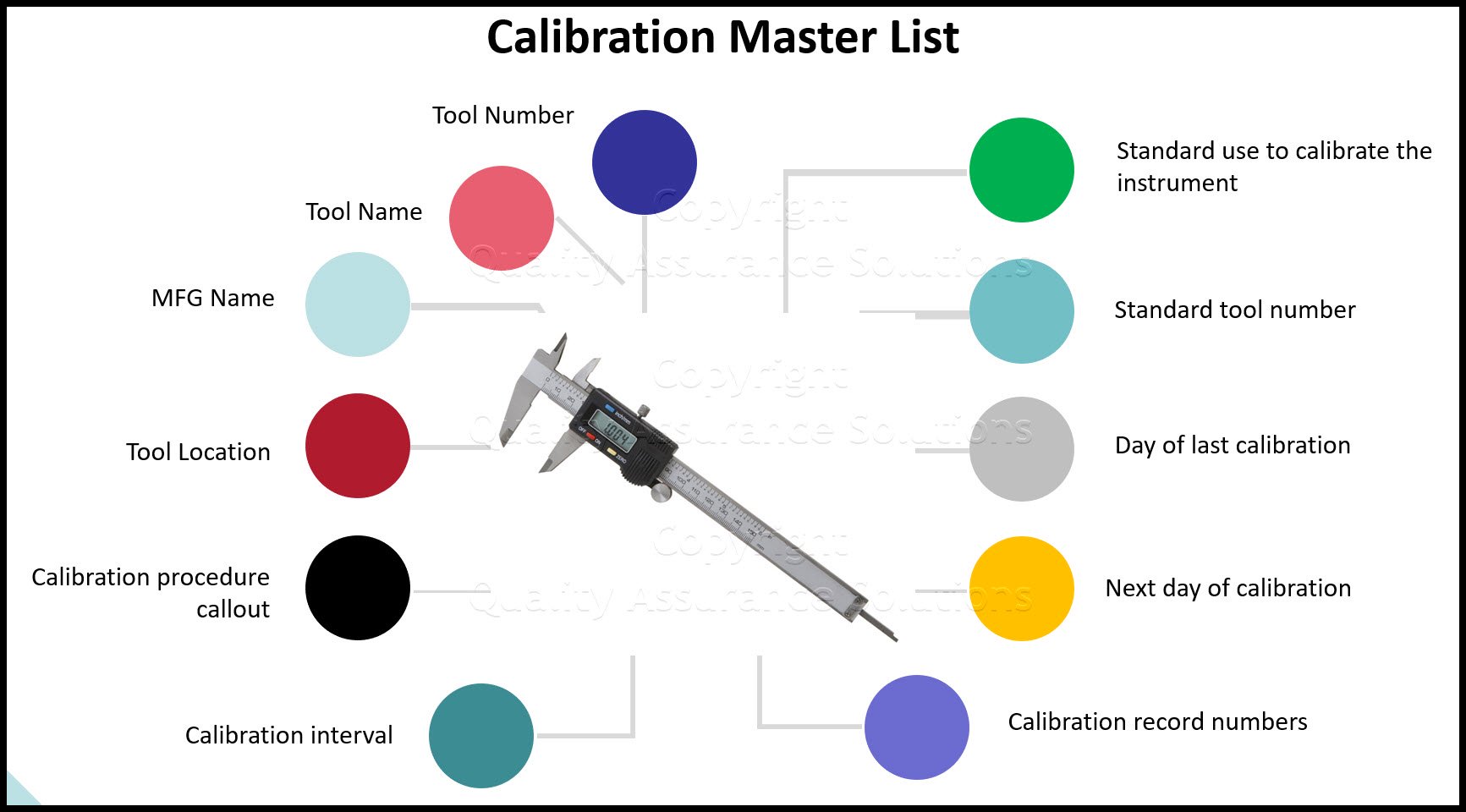

Master List

Tool calibration and control master list should cover these items:

- Tool Number

- Tool Name

- MFG Name

- Tool Location

- Calibration procedure callout

- Calibration interval

- Standard use to calibrate the instrument

- Standard tool number

- Last day of calibration

- Next day of calibration

- Calibration record numbers

Includes an easy to edit Calibration Manual, recommended calibration system, reports and templates.

Calibration Records

Your tool calibration and control records should cover these items:

- Tool Number

- Tool Name

- MFG Name

- Tool Location.

- Calibration procedure callout

- Calibration interval.

- Transfer standard name used to calibrate the instrument

- Transfer standard tool number

- Date of calibration

- Next due date of calibration

- Calibration record number

- Calibration requirements

- Calibration data

- Employee’s name or signature

- Temperature

- Humidity

- Accept / Reject results

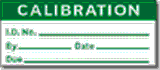

Recommended Calibration Labels

Instrument Calibration Label

- Date of Calibration

- Calibration record number

- Calibration Due date

- Calibration Employee Signature.

Calibrate Prior to Use label. Used for equipment that must be checked for accuracy prior to use.

Reference Only, Not Calibrated label. Used for analog and digital readouts that are monitored with other calibrated equipment.

Do Not Use label. Place on equipment that is out of calibration and not repaired.

Includes an easy to edit Calibration Manual, recommended calibration system, reports and templates.

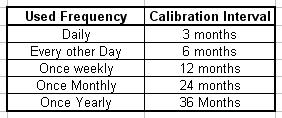

Calibration Interval

Base the calibration interval on the instrument’s stability, purpose, degree of usage, environment, past history of equivalent instruments and manufacturer’s recommendations. You can use the below as a guideline:

Measurement System Analysis

Conducting an MSA study for attribute data

Conducting an MSA study for continuous data.

- QAS Home

- Calibration

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |