Quick Changeover

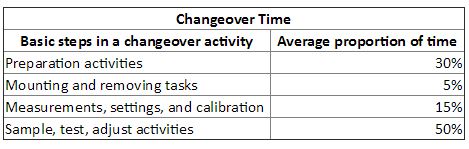

Companies often take a narrow view of quick changeover as only the time required to pull off an existing tool or fixture and set the new tool or fixture. Actually we define changeover as the time between the last good piece from the last production or process run and the first good piece off the next run.

When the process or machine is down because of a changeover, value-added activity ceases. Scrap generated from a process start-up can be significant when a trial-and-error approach is used to adjust the process during the changeover.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Quick changeover is critical to any company wishing to implement One-Piece-Flow. Fast change over lets you apply waste-eliminating techniques for all types of service, administrative, manufacturing, and assembly processes.

You can remove significant waste changeover activities with very little investment in resources. To counter long switch over times many companies produce large lot sizes. However this is not the best method. In fact we recommend reduces lot sizes and focus your efforts on addressing the reasons behind the long change over. Making changeover times quicker and simpler allows companies to produce in smaller lot sizes.

Shigeo Shingo developed single-minute exchange of die (SMED). SMED, a series of operator techniques, targets changeovers of production equipment, fixtures, or processes that occur in less than ten minutes. Even though the target is ten minutes, the long-term goal is always zero changeover time so that changeovers are instantaneous and do not interfere in any way with one-piece flow.

Internal vs External Changeover

Physical changeover includes managing both internal and external changeover tasks:

- You perform Internal activities while the machine or process is shut down or idle.

- You perform external activities while the machine or process is running.

As an initial changeover improvement project, focus on having your external activities for the next production run actually occur during the current production run. Therefore there is no dead time due to external activities.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

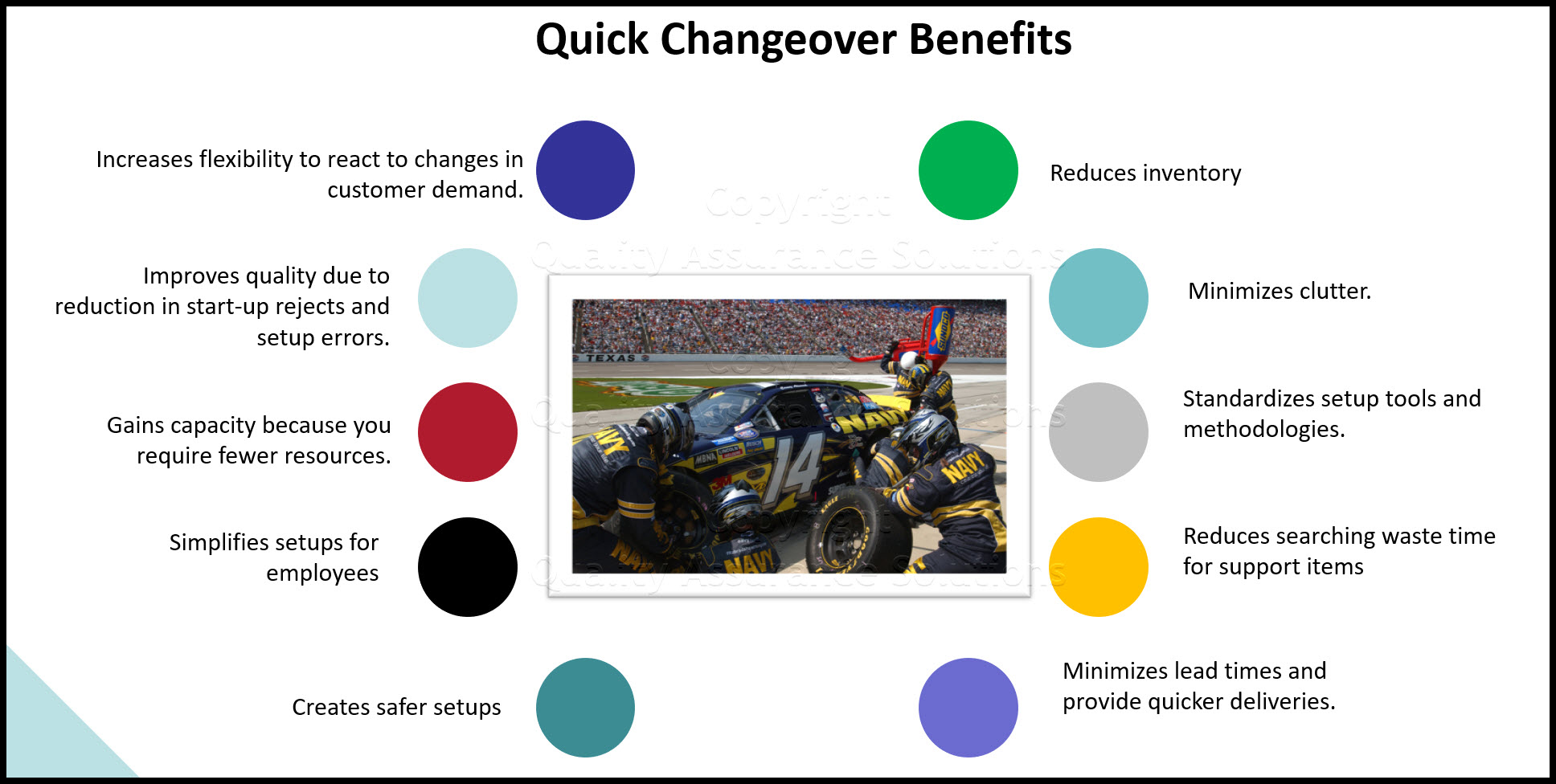

Benefits Of Quick Changeover:

- Increase flexibility to react to changes in customer demand.

- Improve quality due to reduction in start-up rejects and setup errors.

- Gain capacity because you require fewer resources to conduct changeover activities.

- Simplify setups for employees who conduct the changeovers.

- Create safer setups for employees who conduct the changeovers.

- Provide consistency in changeover activities for employees from shift to shift and over time.

- Reduce inventory because of smaller lot sizes.

- Minimize clutter.

- Standardize setup tools and methodologies.

- Reduce searching waste time for support items during changeover activities.

- Reduce motion waste during changeover activities.

- Minimize lead times and provide quicker deliveries.

Quick Changeover is one of the key elements of Lean Manufacturing.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |