Dr. Deming Point 6

Institute Training and Retraining

Knowledge is the only instrument of production that is not subject to diminishing returns.

-J. M. Clark

Below I discuss Dr. Edward Deming's recommended management techniques. Dr. Deming lived from 1900 to 1993.

Dr Deming and Japan's Post WWII Recovery

In 1947 the Allied Supreme Command recruited Dr. Deming to help with the Japanese census. Japan was devastated by the World War II. Dr. Deming became a key person to Japan's economic survival. At this time, Japan's people lived without consumer goods and there was little food to feed their people. They mistrusted their leaders and welcomed the Allied occupation.

Because of the Japanese affability, Dr. Deming took it upon himself to learn the Japanese culture. He studied the Japanese language and befriended the Japanese people. He taught statistics to the Japanese leaders and this in turn help start the Japanese industrial revolution.

TrainingKeeper Software. Keep, organize and plan all your employees' training and activities. Software includes multi-user support with reports, certs, and calendars.

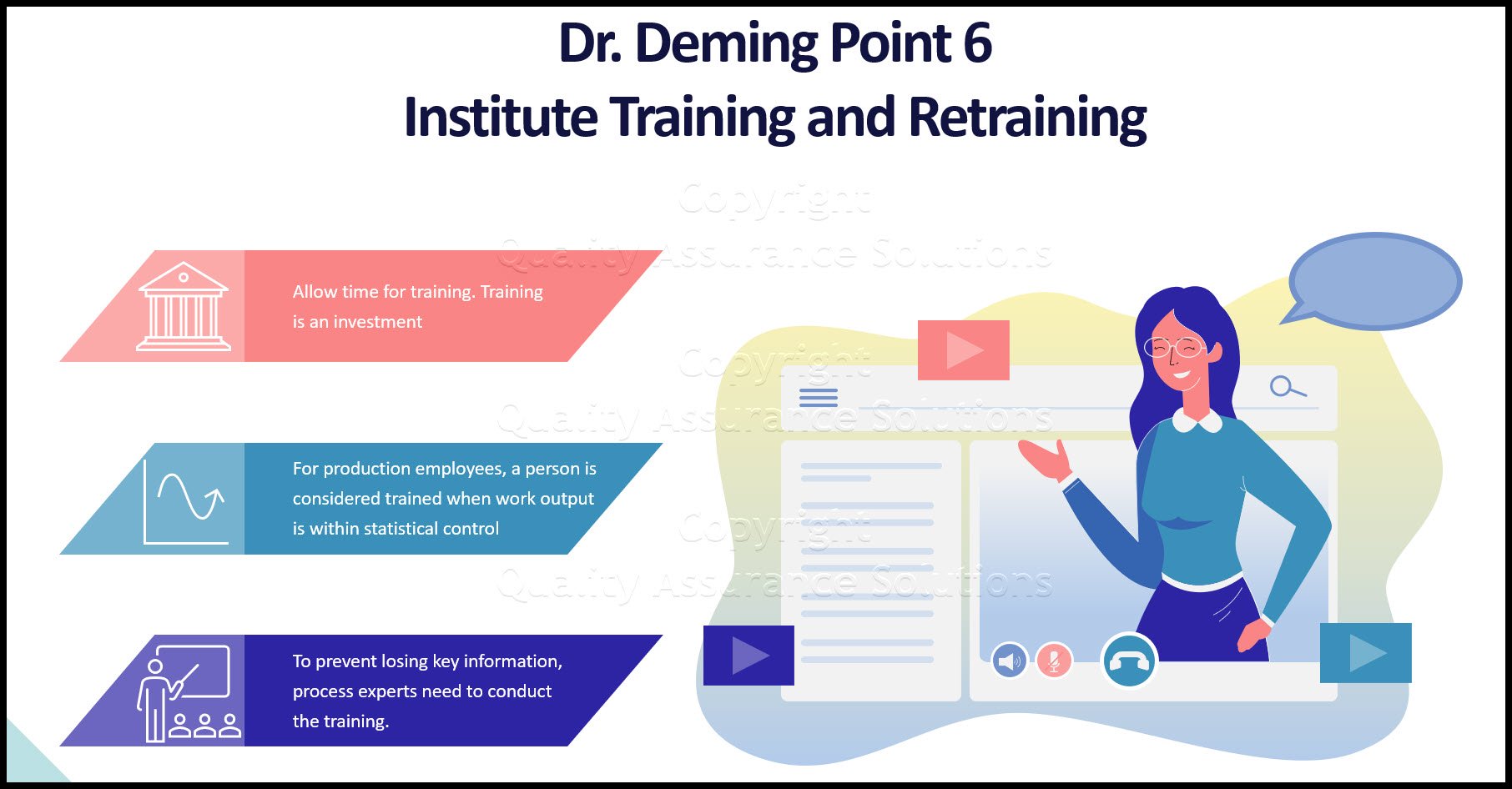

Dr. Deming Point 6 - Train and Retrain

Most companies hire employees and then provide initial training by Human Resources. This training includes general company knowledge, safety issues, and introduction to facilities and key people.

After the initial training, HR sends the employee to their manager, supervisor or lead for on-the-job training. The lead may conduct the training or may assign another knowledgeable party to train this person. Either way, the trainer is responsible for production. Because of the training, the trainer's production will decrease. Management, unknowingly to the root cause, could reprimand the trainers output.

The trainer then has a choice, train the new guy or produce. In addition, can this trainer (another production person) truly teach the correct methods? The trainer teaches only their methods. The new person will be only as knowledgeable as the trainer. It is vital that the trainer be an expert in the process. It is critical that the trainers main responsibility is training new people.

However, I once worked for a company that hired a trainer from outside the company. This trainer had no experience in the production but she was responsible for training all new hires in the production of parts. The company terminated this person after three months of work. Management set her up for failure the day they offered her the job.

Dr. Deming Point 6 believed that a person is considered trained when their production is within statistical control.

Dr. Deming Point 6 also believes in constant training. Management needs to allow for continued training time of all employees.

I worked for another company where one half hour of training a week was mandatory for all employees. The trainers, supervisor, leads and managers were reviewed for this criteria. This assured employees received continued education.

TrainingKeeper Software. Keep, organize and plan all your employees' training and activities. Software includes multi-user support with reports, certs, and calendars.

The trainers documented the training on a training record. This information was then captured by training software called TrainingKeeper. The software let the company schedule future training as well.

I believe all employees need to be trained in statistical analysis. Statistical analysis allows employees to make rational decisions with data.

Dr Deming’s 14 points

1. Create constancy of purpose for improvement of product and service.

2. Adopt the new philosophy

3. Cease dependence on mass inspection

4. End the practice of awarding business on price tag alone

5. Improve constantly and forever the system of production and service.

6. Institute training

7. Institute leadership

8. Drive out fear

9. Break down barriers between staff areas

10. Eliminate slogans, exhortations, and targets for the workforce.

11. Eliminate numerical quotas.

12. Remove barriers to pride of workmanship.

13. Institute a vigorous program of education and retraining.

14. Take action to accomplish the transformation.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |