Dr Deming Point 4

End the Practice of Awarding Business on Price Tag Alone

Below I discuss Dr. Edward Deming's recommended management techniques. This page discusses Dr. Deming Point 4.

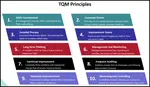

Dr. Deming lived from 1900 to 1993. Dr. Deming is considered by many as the father of TQM (Total Quality Management). Six sigma concepts can be tracked back to Dr. Deming and other quality gurus of the past.

TrainingKeeper Software. Keep, organize and plan all your employees' training and activities. Software includes multi-user support with reports, certs, and calendars.

Dr. Deming had many odd jobs when he was a youngster. As a janitor, he mopped floors. He shoveled snow and cut ice. In a drug store he worked as a soda jerk. After college he taught engineering and mathematics. He worked at Western Electric in Chicago as an engineer focused on improving transmitters.

Since Western Electric was conducting many production management studies to improve workforce production output, Dr. Deming learn the basics of his important management style. He also worked for the Department of Agriculture with a focus on Nitrogen’s relationship with plant growth. Here, he used statistical process control.

Get certified in Risk Management through our completely on-line training system. Study at your own pace.

End the Practice of Awarding Business on Price Tag Alone - Deming Point 4

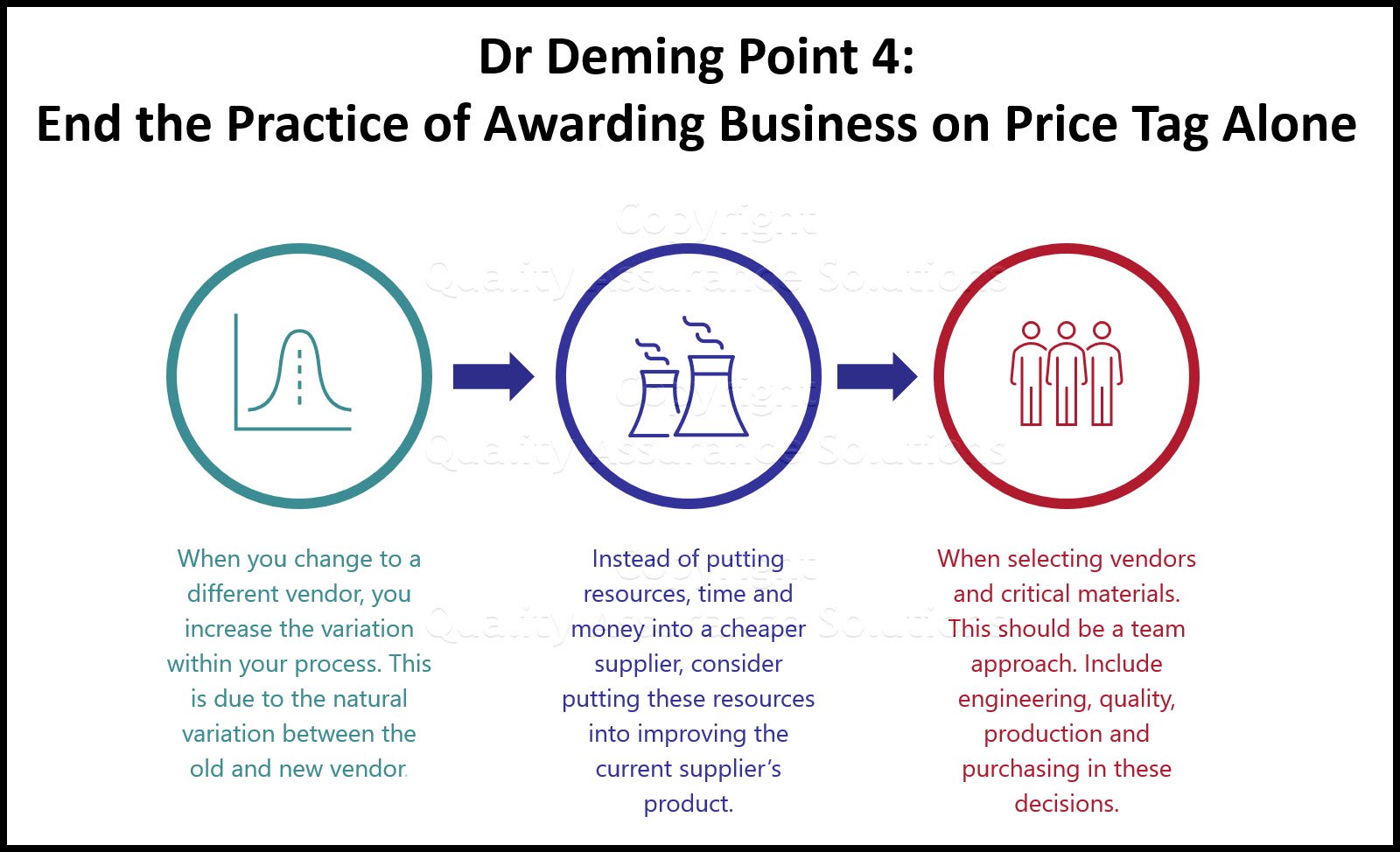

In these economic times, all companies push to save dollars. Purchasing managers find cheaper goods and switch to the vendor that provides the cheapest material. If this is a critical material, then this practice will actually increase total cost. Dr. Deming Point 4 states “Price has no meaning without a measure of the quality being produce."

When you change to a different vendor, you increase the variation within your process. This is due to the natural variation between the old and new vendor. The new vendor's material may meet specification, but most likely you will need to adjust your company’s processes to work with the new material. How much time and money will your company spend to adjust the processes to work with the new vendor’s material?

Your final product quality depends on the raw materials used or consumed during the process. When these raw materials change, you create undesirable variation which can snowball into other processes.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Instead of putting resources, time and money into a cheaper product, consider putting these resources into improving the current supplier’s product. Work with that vendor and let them know how to improve their materials to make your process better.

In addition, how much time and money will be spent to form a new relationship with the new vendor? When you change vendors, you have no history of lot to lot variation. The first lot of material might be perfect. It should be because that new vendor is trying to get your business. But when you switch, you do not know what is coming. For a price cut are you willing to take a chance on the unknown?

When selecting vendors and critical materials. This should be a team approach. Include engineering, quality, production and purchasing in these decisions. This method prevents someone from making a poor decision based on price alone.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Dr Deming’s 14 points

1. Create constancy of purpose for improvement of product and service.

2. Adopt the new philosophy

3. Cease dependence on mass inspection

4. End the practice of awarding business on price tag alone

5. Improve constantly and forever the system of production and service.

6. Institute training

7. Institute leadership

8. Drive out fear

9. Break down barriers between staff areas

10. Eliminate slogans, exhortations, and targets for the workforce.

11. Eliminate numerical quotas.

12. Remove barriers to pride of workmanship.

13. Institute a vigorous program of education and retraining.

14. Take action to accomplish the transformation.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |