What Is Quality Assurance?

To understand What is Quality Assurance? you need to understand that Manufacturers' understanding of quality assurance changed and grown over the last sixty years or more. Prior to that time, they believed that quality happens when they made products well and provided services efficiently .

Back then, they measured Quality generally by inspection. They closely checked the products when they came off the assembly line, but only after they made them. If they found any materials or products with errors, they sent these back to be corrected, reworked, or scrapped. The fewer the number of errors, the greater the quality of the product.

The manufactures did not give much scientific thought about what went into the step-by-step process that produced a product or rendered a service.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

People recognized quality when they saw it and when it happened. For example,

- Customers knew delicious

restaurant food and good service

- The 48 clothing materials of the highest fibers

- When automobiles worked well,

- When employees managed time well managed

- A well written book

- When music sounded good.

- When teachers understood their subject

- When production increased

- When costs reduced, or services improved.

The list could go on forever.

After a while, manufacturers realized that the traditional method of inspecting products for errors after they were made was foolish, time consuming, and costly. They felt quality could be measured and defined more scientifically. What is Quality Assurance? They asked serious questions

- What is quality?

- Can we set quality goals before making a product or offering a service?

- Can we prevent errors up front rather than pick up the pieces at the end?

- Can we catch errors during the manufacturing process?

- Can we use scientific tools to measure quality in an on-going manner?

- Can we create standards based averages and normal distribution of goods?

Your easy to edit ISO 9001:2015 Quality Assurance Manual.

Industrial engineers

investigated new ways to measure quality and developed what is known today as

quality assurance (QA). This article attempts to answer What is Quality Assurance?

Webster's dictionary defines quality as "a degree of excellence". Assurance means "certainty or sureness". According to Webster, quality assurance is a program for the systematic monitoring and evaluation of the various aspects of a project, service, or facility to ensure that standards of quality are being met

ASQ defines Quality Assurance as "all the planned and systematic activities implemented within the quality system that can be demonstrated to provide confidence that a product or service will fulfill requirements for quality".

Quality assurance begins with a philosophy that has two basic beliefs:

- Quality can be scientifically measured.

- Quality can be measured on a continuous basis.

What is quality assurance means committing to excellence, focusing continuously on improving products or services. Opportunities for growth and improvement never end.

Would You Hire Employees with 90% Reliability?

Without much thought, the answer to this question might be, "Surely, I would." It sounds pretty good at first. After all, 90% in education means an "A". Most students would be satisfied with that.

When employers hire employees who are 90% reliable, it means workers can be depended on 90% of the time and not be depended on 10% of the time.

Let's rephrase the

question. Would you like the computer in a large city bank to operate 90% of

the time? Would you wish your car to drive only 90% of the time? Would you like

your microwave oven (or refrigerator, stove, television, etc.) to work 90% of

the time? Would you fly in a 90% reliable airplane? Most people would not want to test

that quality twenty thousand feet in the air.

What is quality assurance when three employees are 90% reliable? A simple math example answers that question.

Multiply worker 1's reliability with worker 2

90% x 90% = 81% (reliability is 81%)

Multiply worker 3's reliability with 90%.

81% x 90% = 72.9% (reliability is 72.9%)

Because of this, your company must hire employees committed to improving their work and work situation each

day.

This article presents an overview and simple explanation about

- what is quality assurance

- how you develop QA

- how you measure it and bring it under control,

Knowing the basic principles about quality assurance builds job opportunities and provides the groundwork for becoming a reliable employee.

TrainingKeeper Software. Keep, organize and plan all your employees' training and activities. Software includes multi-user support with reports, certs, and calendars.

Historical Development of Quality Assurance

Many men and women developed and contributed to the field of Quality Assurance. Quality experts include Philip Crosby, Walter A. Shewhart, Dr. W. Edwards Deming, and Dr. Joseph M. Juran. This article concentrates mainly on the work of Dr. Deming because most regard him as the founder of the new economic industrial era.

Deming received his doctorate in statistics from Yale University. He was a student of Dr. Walter Shewhart who pioneered statistical process control (SPC). Deming used his ideas to developed methods of using numerical data to improve quality production.

Dr. Deming and What is Quality Assurance.

Deming's Quality Assurance methods improved industrial products needed for World War Il. In fact, Japanese engineers amazed at the quality of the US military equipment captured during the war. They recognized the superiority of American goods. At that time, most people considered any product labeled, "Made in Japan" inferior.

A critical

industrial shift took place in the United States after the War. The masses

greatly demanded consumer goods. Americans wanted to make up for the material

goods they lacked during the war. Plus US experienced no foreign competition because

industrial countries needed to rebuild their own industries. Consequently, United States' businesses and industries prospered during the post war era.

Workers wanted to make quality products but management did not support this. Managers got all caught up in quantity (mass) production that brought high profits. The downside of mass production, companies lost interest in quality production.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

On the other

hand, Japan knew it had to make major changes to compete in the world

market. Japanese leaders invited Dr. Deming to show them how. Deming did not

want Japan to repeat the United States mistakes. For quality

assurance to work, Deming maintained, it needed the total support of

management. This philosophy became known as Total Quality Management (TQM).

In Japan, managers applied Deming's Total Quality Management methods and built a strong industrial base. By the 70's, quality assurance was in full swing, If anyone wanted quality products, they bought them from Japan.

Since the 1980's, with the assistance of Dr. Deming, United States industries successfully returned to Quality Assurance (QA). Quality assurance gradually replaced quantity production. Management by quality replaced management by quantity. The world market today provides great competition.

Companies must

produce quality products and services if they wish to stay in business. What is Quality Assurance? It

makes the difference between a company's success or failure. Implement

quality assurance or go out of business.

How True is This Story?

Once upon a time an American aerospace company and the Japanese

decided to have a competitive boat race on the Tennessee river. Both teams

practiced hard and long to reach their peak performance. On race day, they both

felt ready and certain they would win.

The Japanese won by a mile!

Afterwards, the American team became very discouraged by the loss and morale sagged. Corporate management decided that the reason for crushing defeat had to be found. A continuous measurable improvement team was set up to investigate the problem and recommend appropriate corrective action. Their conclusion:

The problem was that the Japanese team had eight people rowing and one person steering; whereas, the American team had one person rowing and eight people steering. The American corporate steering committee immediately hired a consulting firm to do a study on the management structure.

After some time and millions of dollars, the consulting firm concluded that: too many people were steering and not enough were rowing.

To prevent losing to the Japanese again the next year. The team's

management structure was totally reorganized to four steering managers, three

area steering managers, one staff steering manager, and a new performance

system for the person rowing the boat.

The next year the Japanese won by two miles.

Humiliated, the American corporation laid off the rower for poor performance, sold the paddles, canceled all capital investments. For new equipment, halted development of a new canoe, gave a "High Performance" award to the consulting firm. Then they distributed the money saved as bonuses to the senior executives.

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

Statistical Process Control (SPC)

As mentioned earlier, Dr. Deming developed a data-based or scientific approach to quality assurance. Deming felt that inspection alone did not improve quality. He believed that quality happened controlling the production while in process.

This data-based or scientific approach to quality assurance is called Statistical Process Control or SPC for short. This means that every step in the total production process is studied and brought under control by means of statistics and statistical tools. SPC is the backbone of quality assurance and helps create a climate of excellence.

- Statistical - a science that deals with numbers, facts, and data

- Process -a series of continuous actions

- Control- regulate or exercise direction over

Meaning of Statistics

Statistics uses numbers, facts, and data for the purpose of solving problems and

improving quality. With statistics you...

- Identify problems

- Help understand the actual situation

- Eliminate defects and errors

- Provide data for analysis and decision making

- Bring operating process under control

- Improve the working process

To improve, you gather, organize, and record statistics with

statistical tools. Statistical tools include charts, graphs, and diagrams which visually show

when things aren't working as well as expected. There are many types of

statistical tools. You choose which tool to use based on the project under study. The most commonly used statistical tools are listed below.

A process is a group of step-by-step activities that are directed toward particular outcome. Each step is performed in sequence; that is. one step follows another.

Each step is related to and affects all the other steps.

This Data Analysis Video teaches you the basic tools for understanding, summarizing, and making future predictions with your collected data. Includes MS Excel templates.

Processes and End Results.

The process is as much a part of what is quality assurance as the end result. Knowing the steps that go into making a product or service means knowing the end result. Understanding every step of the process helps to know the starting point, the ending point, and everything that happens in between. Rather than check only the final product, you check every step along the way. Should a problem occur, "what is quality assurance?" means stopping the process and fixing it. Quality Assurance helps eliminate problems in the process.

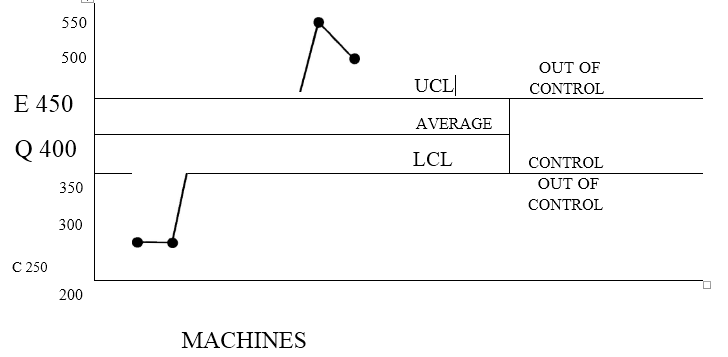

Meaning of Control

How do

manufacturers know when a problem exist in the process? They can predict or

foretell, over a period of time, how a process operates under normal conditions

and circumstances. They gather statistical facts and find an

average. You calculate an average by adding the total number of facts and dividing

that by the number of observations.

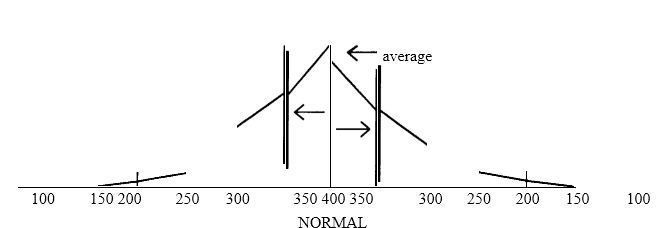

For example, a supervisor wants to know the daily average number of products made on machines "A" through "G"

A 250 Total: 2800

B 250 Avg: 400

C 475

D 400

E 350

F 500

G 475

In the example above, add the total number of products made (2800) by the number of machines (7) that produced the product. The average represents the "normal distribution" of a product or where the average amount of data normally falls. Normal distribution is often illustrated on a bell-curved diagram like the one below.

To promote quality performance, you establish standards for each step in the process. You then use these Standards for making judgments about the quality of the product. They help create error-free defects and determine whether a product is fit for use.

Steps of Statistical Process Control

- Study the process

- Develop uniform standards

- Develop error-free process to eliminate and prevent errors

- Reduce causes of out of control variations

- Bring variations under control

- Begin all over again

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Characteristics of Good Standards

What are some of tie features that go into good quality standards? Consider the following points. Standards should:

- Meet and exceed customer expectations and satisfaction

- Come as close as possible to error-free defects

- Planned and agreed upon by all persons concerned (employees, customers)

- Supported by management

- Communicated effectively and taken seriously by all persons concerned

- Workable and understood by all

- Followed and changed as needed (outdated, not working, better idea)

- Measured and compared against the end result

- Included in the total organizational plan for improvement

- Included in the educational program on how standards can be implemented and continuously improved

- Be celebrated or rewarded when achieved.

Article written by Massachusetts Career Development Institute. This article is Federally-funded, or carries its own permission to reproduce, or is otherwise in the public domain. Article posted and updated by Quality Assurance Solutions.

- QAS Home

- The Basics

- What Is Quality Assurance

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |