8D Problem Solving

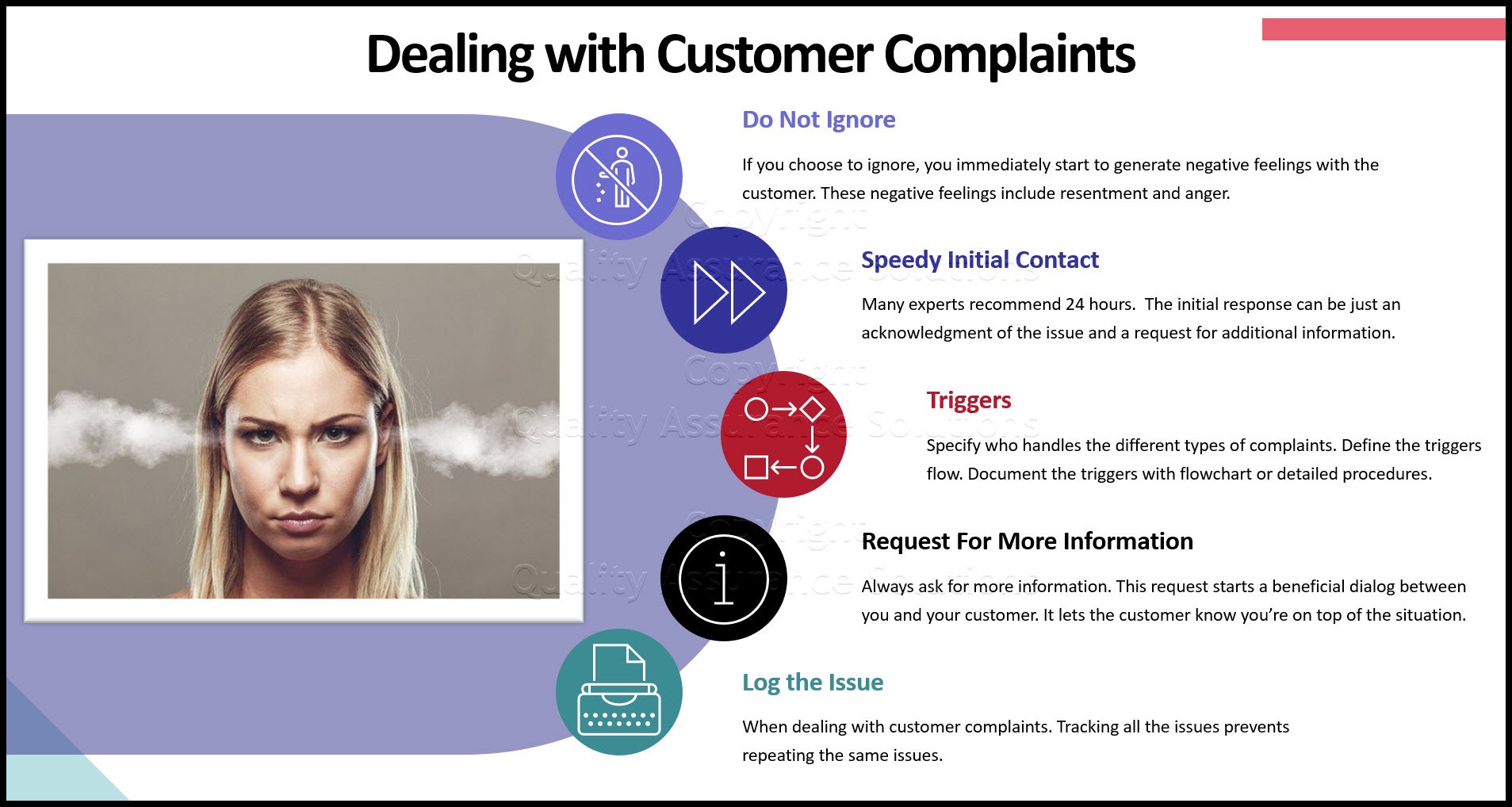

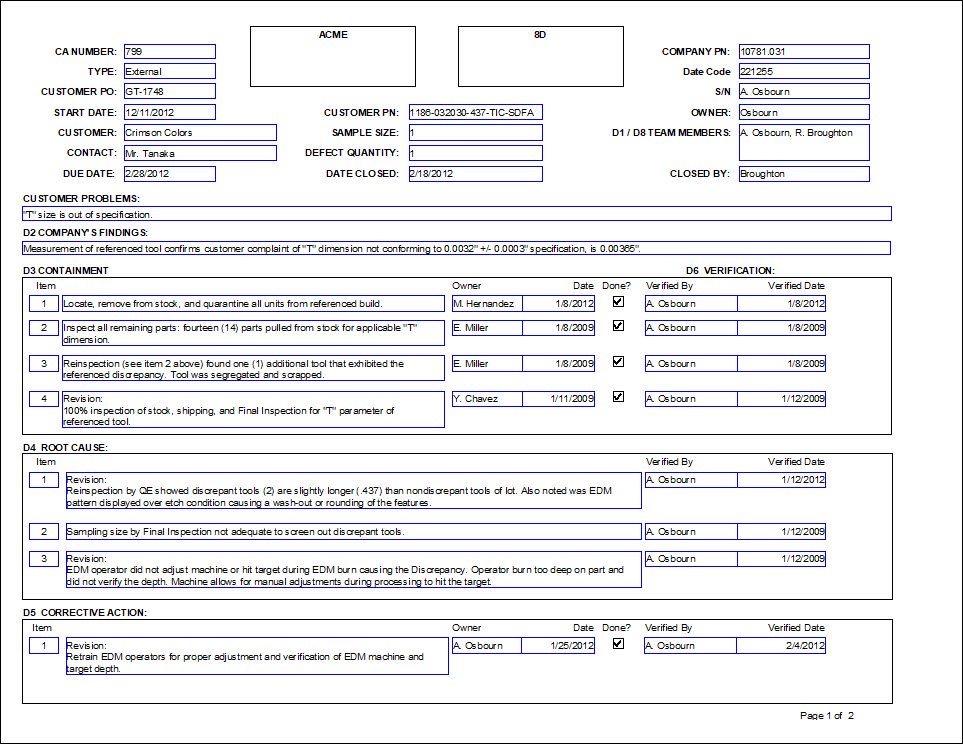

When a customer issues you a corrective action you should follow the 8D problem solving methodology

system. 8D stands for 8 Disciplines. The 8D approach is a complete approach to solving problems. Most customers require an 8D problem solving report for their corrective action request. The easiest approach to creating an 8D report is using 8D software.

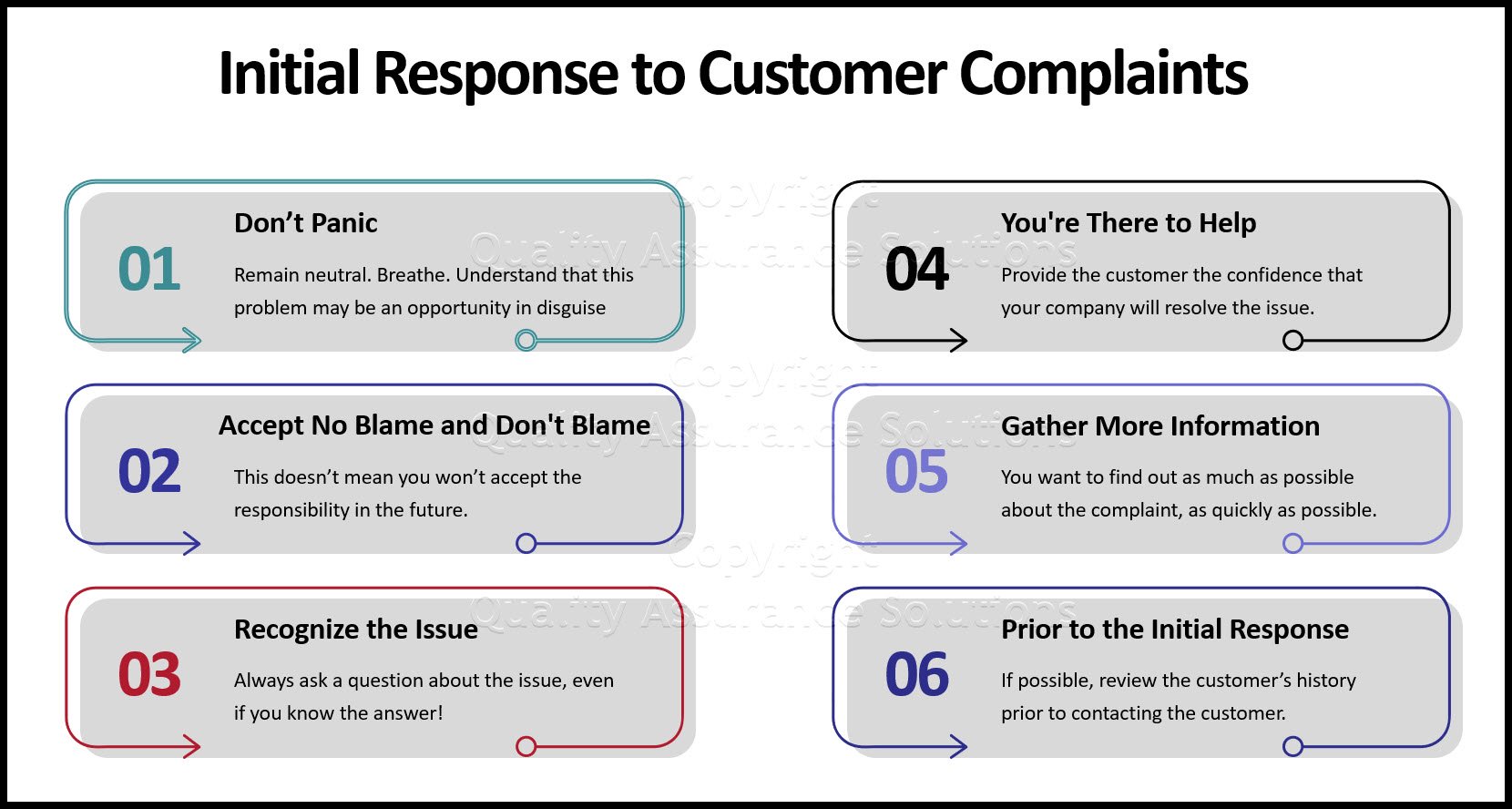

Customer Expectations

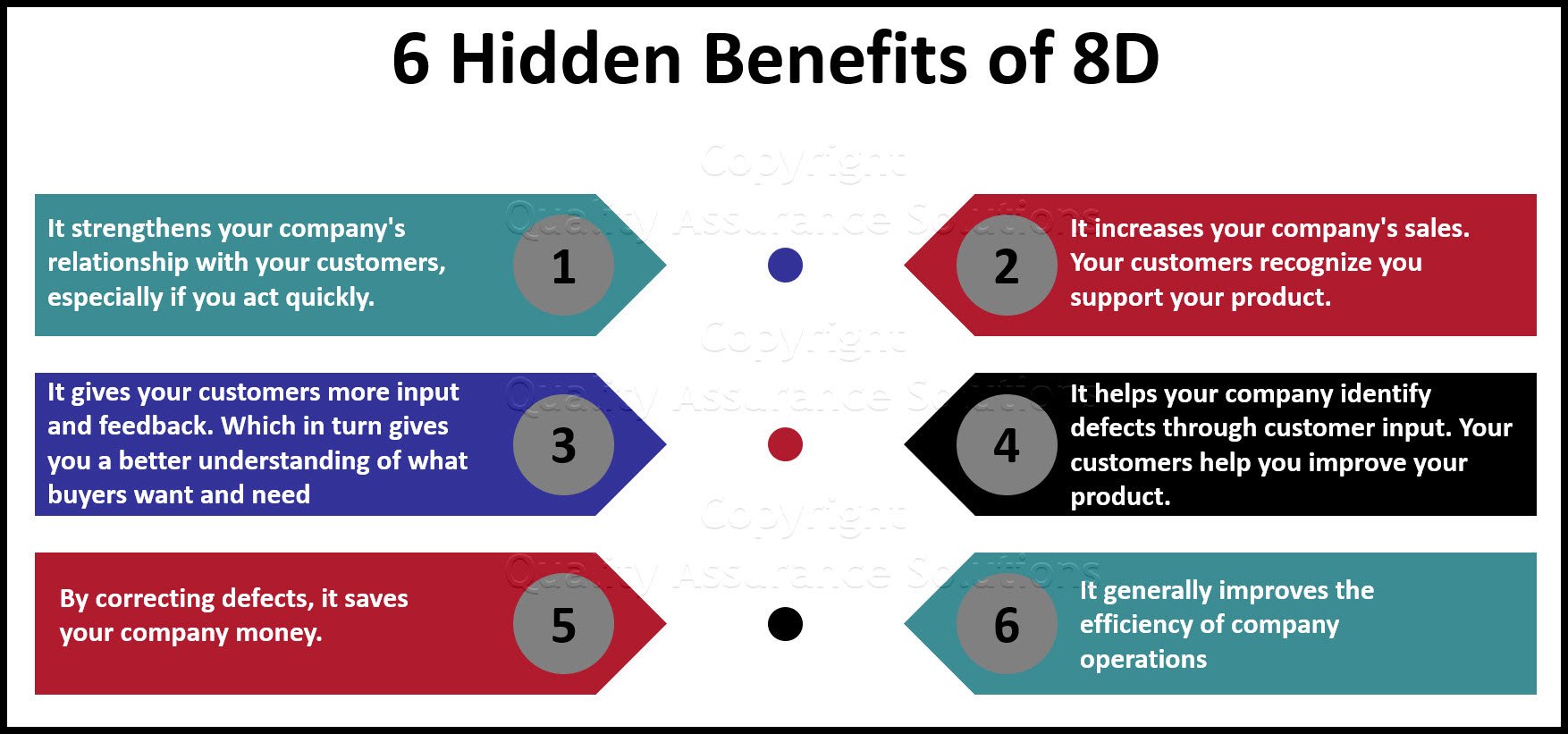

After notification of a problem, your customer expects you to take the appropriate steps in a timely manner to resolve that problem. The quicker you address the issue, the more satisfied your customer. A thorough 8D problem solving corrective action has these additional benefits:

- It can strengthen the bond between your company and your customer.

- It can improve sales with your customer.

- It opens a new line of communication between your company and your customer.

- It prevents defects from escaping at your location.

- It corrects defects which saves you money.

- It helps guide you in future improvement efforts.

For these reasons you should follow the 8D problem solving technique.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

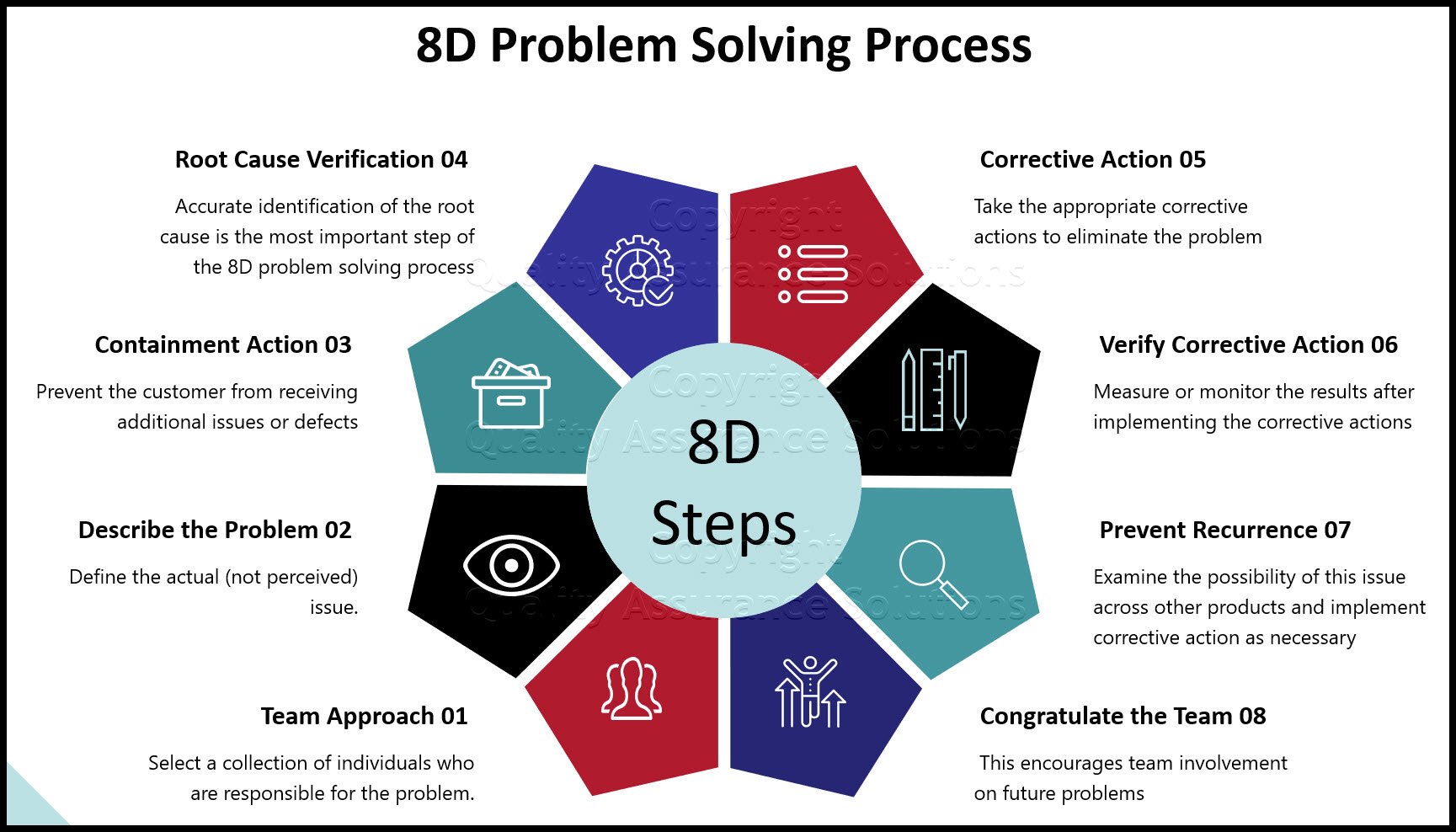

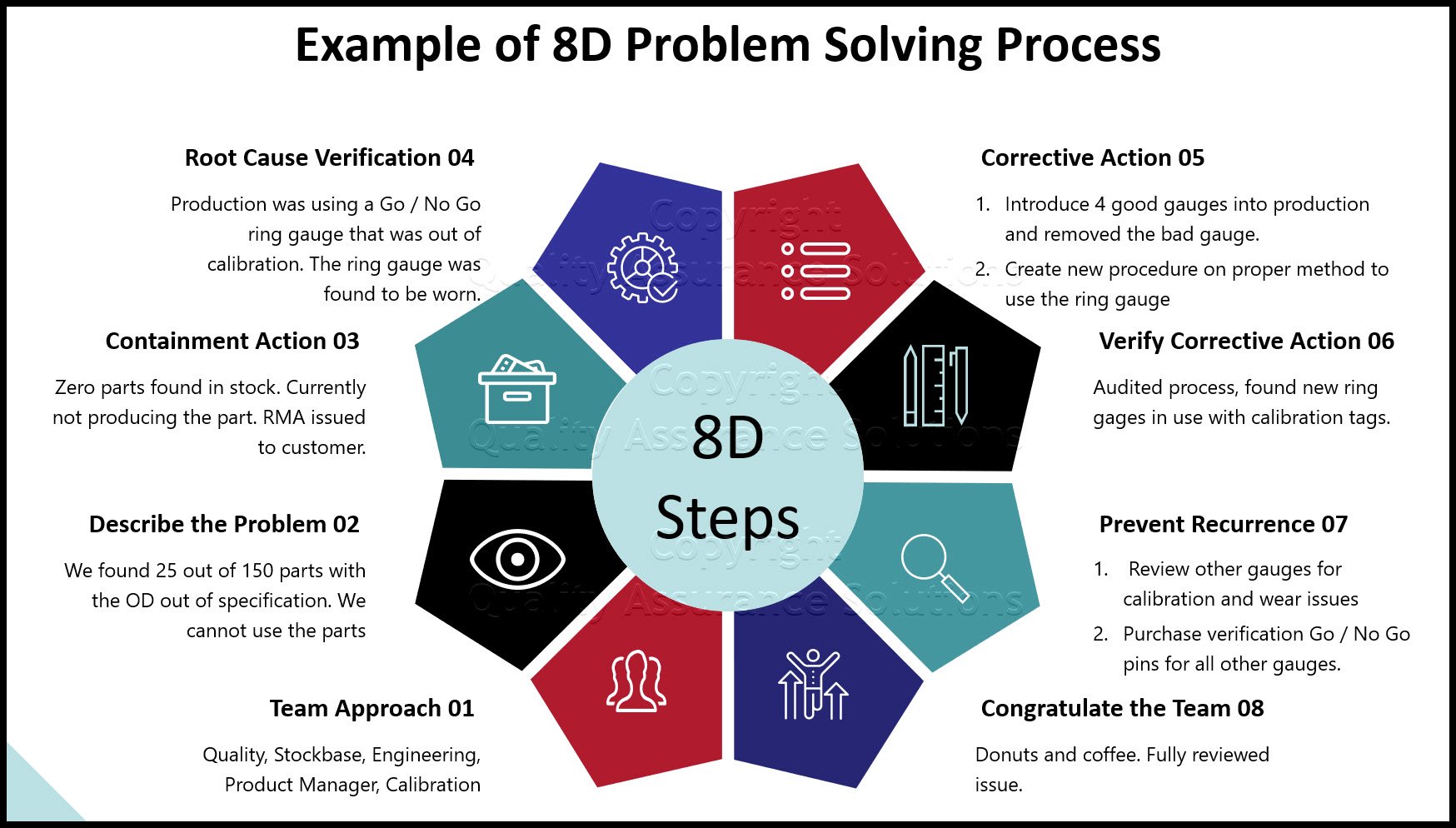

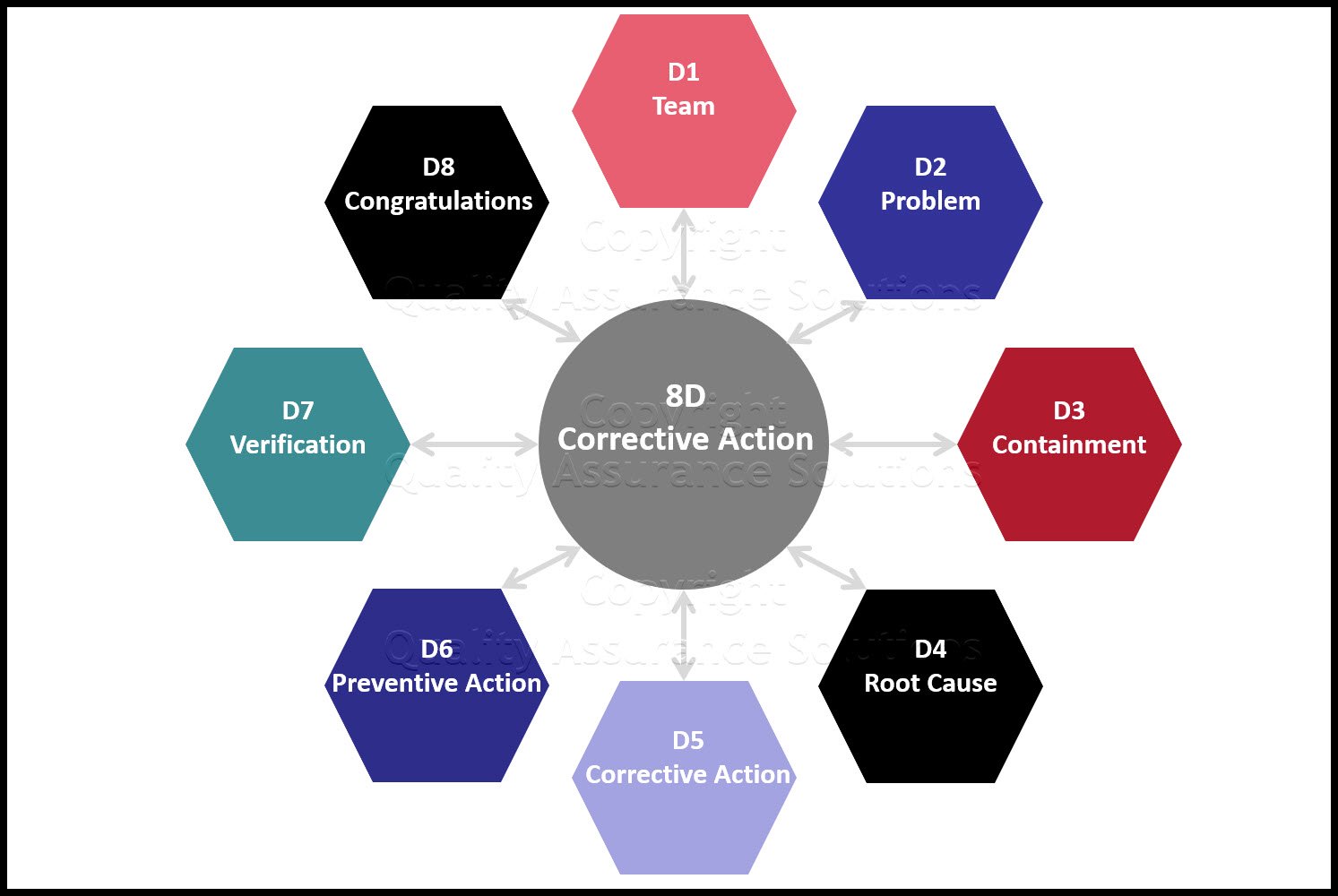

8D Problem Solving Methodology Steps

Your 8D report documents the below steps.

- Team approach

- Describe the Problem

- Containment Action

- Root Cause Verification

- Implement Corrective Action

- Verify Corrective Action

- Prevent Recurrence

- Congratulate the Team

Team Approach

When resolving a problem, usually the problem is not resolved by one person. Select a champion who guides the team through the 8D approach. Include process experts for the team. Select a collection of individuals who are responsible for the problem.

Give the team the authority and responsibility for making the improvements. Click here for more on the team approach.

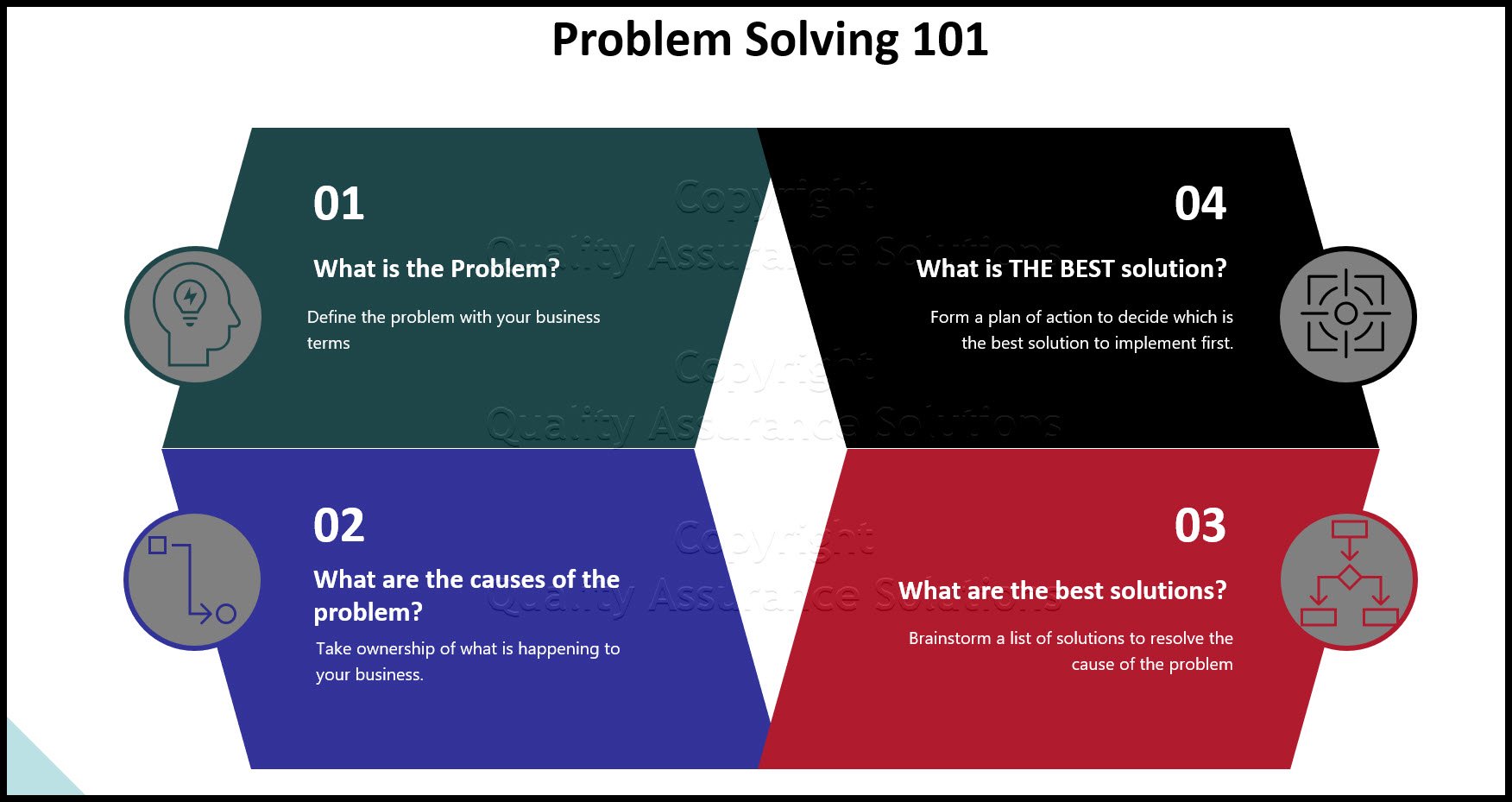

Describe the Problem

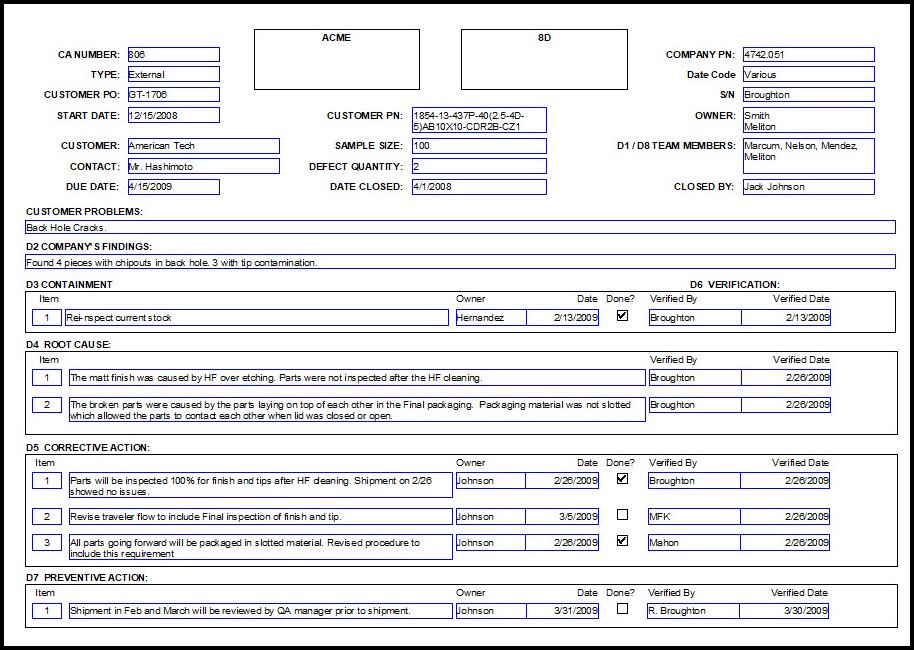

Your 8D report should include two descriptions of the problem. The first is the description from the customer's point of view. Find this information on the customer's corrective action request.

The second description is your statement of the actual issue. Many times the customer sees one thing but in actuality it is another problem. You define the problem in your terms. For example; a customer may say the part is not polished. Your findings show the part is polished but there are finger smudges on the part.

Your statement is the D2 of the 8D process.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

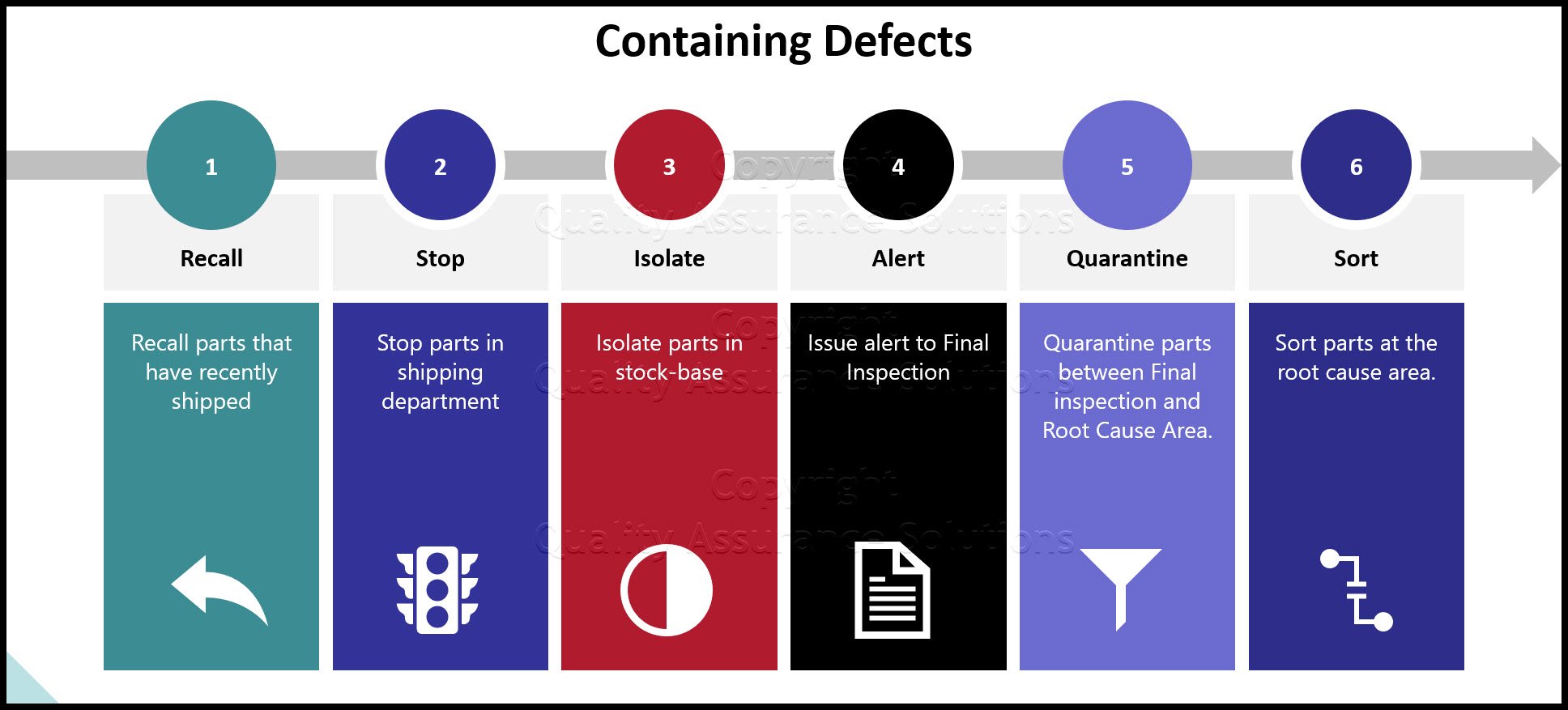

Containment Action

Your company takes action to prevent the customer from receiving additional parts with the defect. Your team reviews these areas:

- The customer’s parts in your stock

- The customer’s parts between the identified root cause area and your stock

- The customer’s parts at the identified root cause area

- The customer’s parts in shipping or during shipping

- The customer part’s in stock at the customer location

During the 8D Problem Solving methodology process your team decides upon the appropriate containment actions which depends on the nature of the problem. Document these actions in the 8D problem solving report. Your customer reviews this information and needs to feel comfortable that you contained all suspect parts.

See here for more details on containment

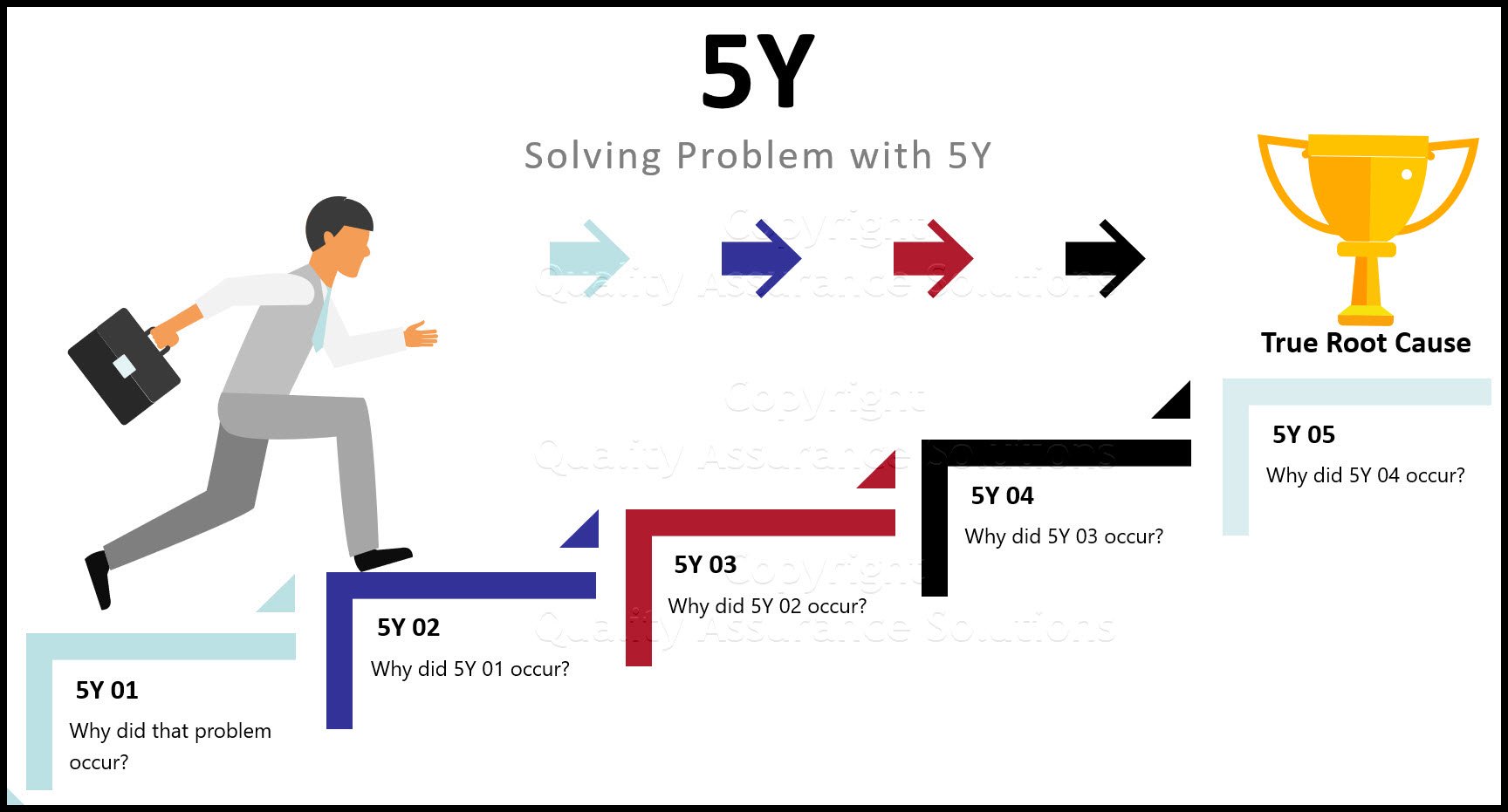

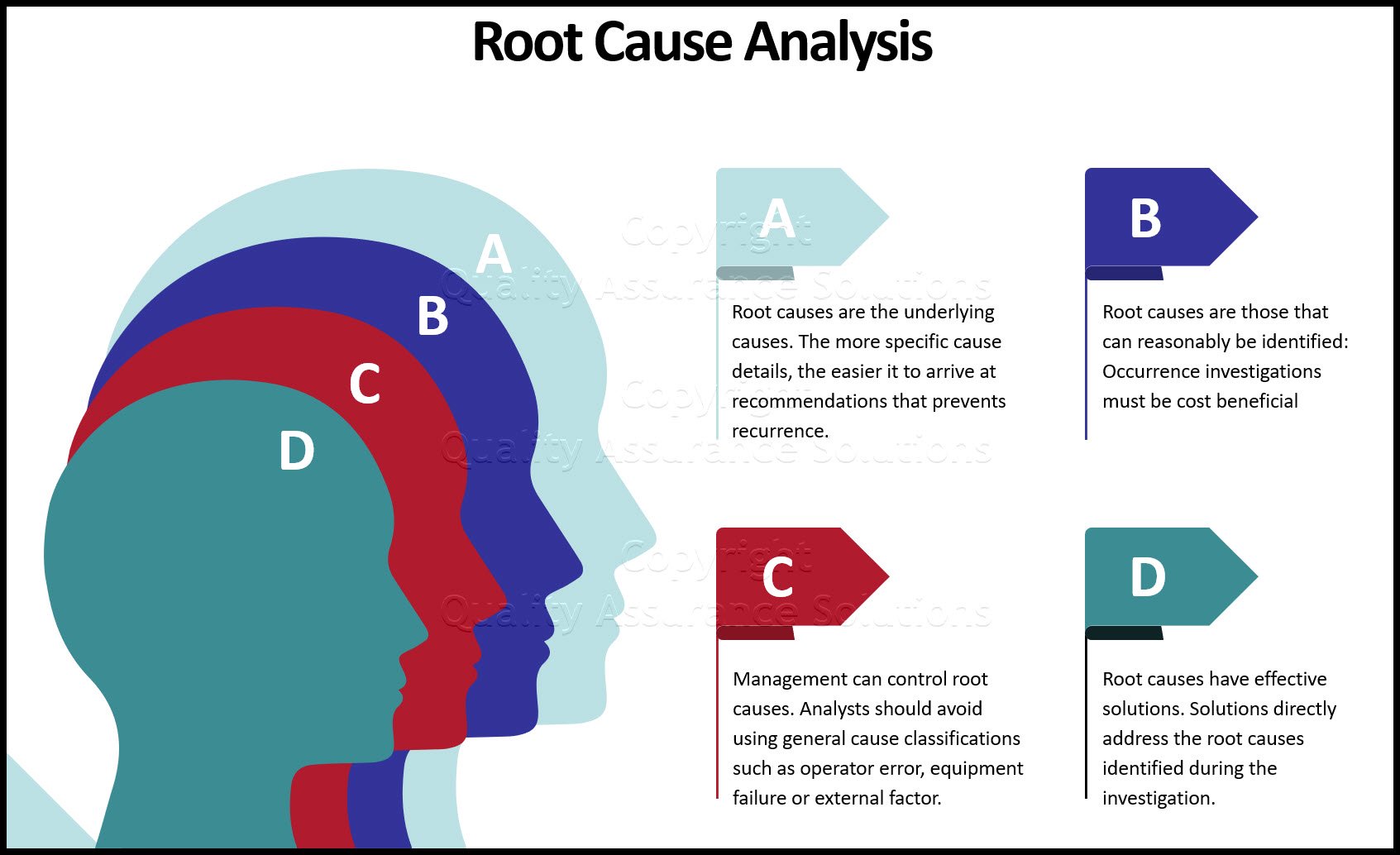

Root Cause Verification

Root cause verification may be the most difficult step of the 8D problem solving system. To help the team attack this, review the 4Ms. 4M stands for machine, material, man and method.

Was the problem caused by a machine? Machine setup? Machine tooling? Machine settings? Machine wear?

Was the problem caused by a person (man)? Training Issue? Sleep depreciation? Carelessness?

Was the problem caused by raw material? Supplier Issue? Poor traceability? Wrong material?

Was the problem caused by method? Process problem? Inaccurate procedure? Missing info in the procedure? No procedure? Wrong revision?

If necessary, use a fishbone diagram which focuses on the 4M.

After brainstorming the root cause, the team verifies the root cause. The team recreates the problem by witnessing the root cause in action. Accurate identification of the root cause is the most important step of the 8D problem solving process because it assures you put your efforts, resources and money in the right place. Problems will reoccur with poor root cause determination.

The team could encounter many root causes. Document all causes on the 8D report. Your customer will review this. Make your statements clear and understandable for your customer.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Implement the Corrective Action

After you identified the root cause, your team takes the appropriate corrective action to fix it. It is almost impossible to list all possible corrective actions as these depend on your situation.

In general, corrective action normally takes the most time and cost of the 8D problem solving methodology steps. Complete the corrective actions in a reasonable amount of time to satisfy your customer. Do not delay spending money to fix the problem. The money spent keeps your customer from walking away.

Your 8D report documents the corrective action steps, responsibilities and completed due dates. Make the actions clear, responsive, and relevant for your customer review.

Verify the Corrective Action

Your team verifies the corrective action by measuring or monitoring the results after implementing the corrective actions. Verify the customer’s problem cannot be recreated. Verification includes reviewing documentation that supports the process changes from the corrective action. Complete the verification activity by someone who did not implement the corrective action.

Let your customer know when the verification occurred. This helps the customer reset the clock for the problem.

In addition, verify the containment action and preventive action activities.

Document these verification actions on your 8D problem solving report. Include the responsible name and date on the report.

Preventive Actions

Pursue these steps to prevent the issue from reoccurring in the future. Possible preventive actions includes

- Examine this issue across other production lines and implement corrective action as necessary

- Schedule periodic training for the corrective action

- Schedule periodic audits for the problem and corrective action activities

- Include additional reviews or data collection for the problem.

- Update FMEA and quality plans

Document these preventive items on the 8D report.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Congratulate the Team

It takes significant effort to resolve a problem. Upper management and the team leader need to congratulate the team. This encourages team involvement on future problems. Normally, you don't document the congratulated actions or share these with your customer.

Sample of customer complaint letter.

- QAS Home

- 8D Reports

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |