Containment Theory

This page discusses containment theory. It is broken down between external containment (at your customer location) and internal containment (at your facility). In addition, I cover warranty issues and containment.

External Containment

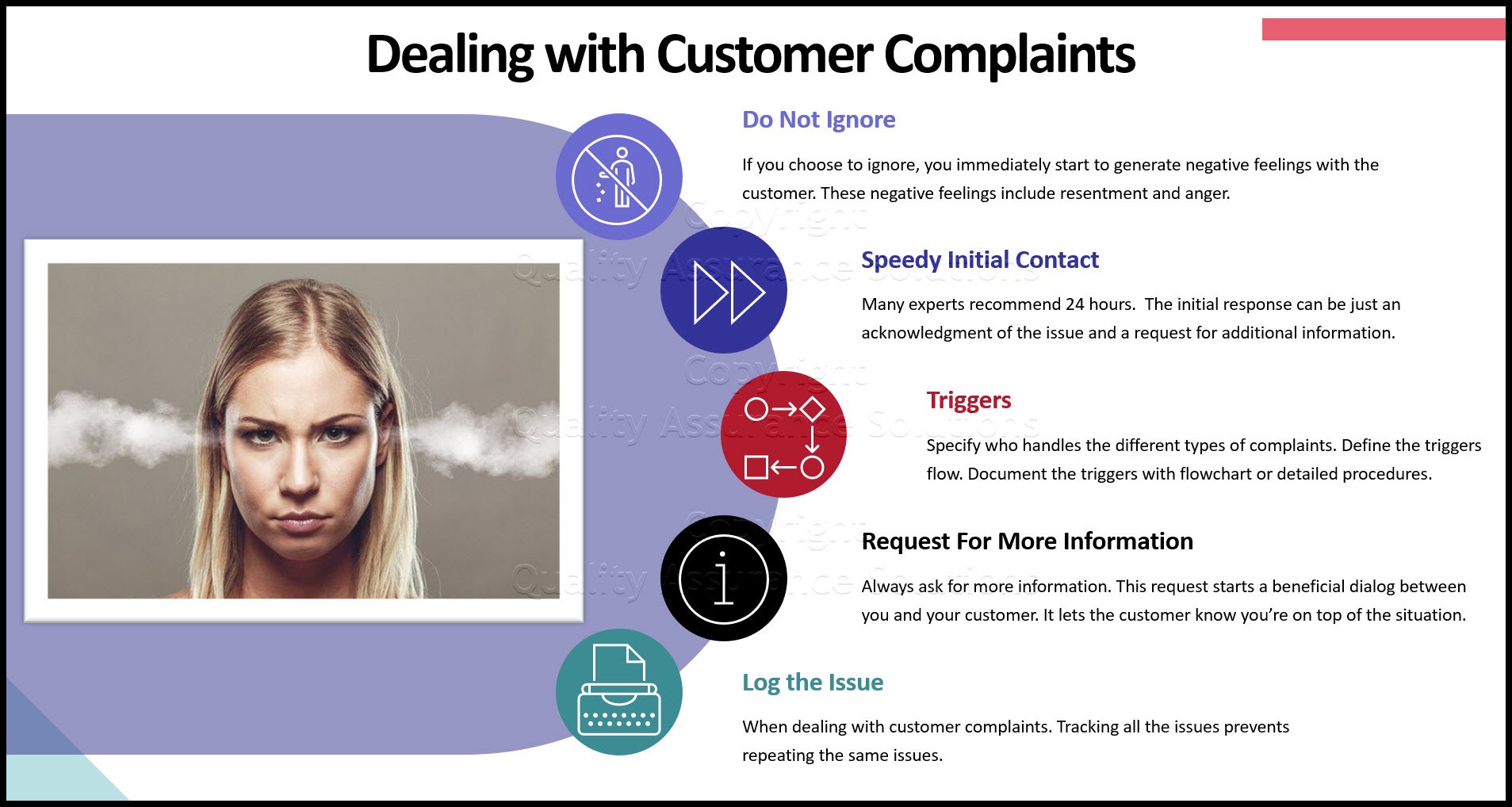

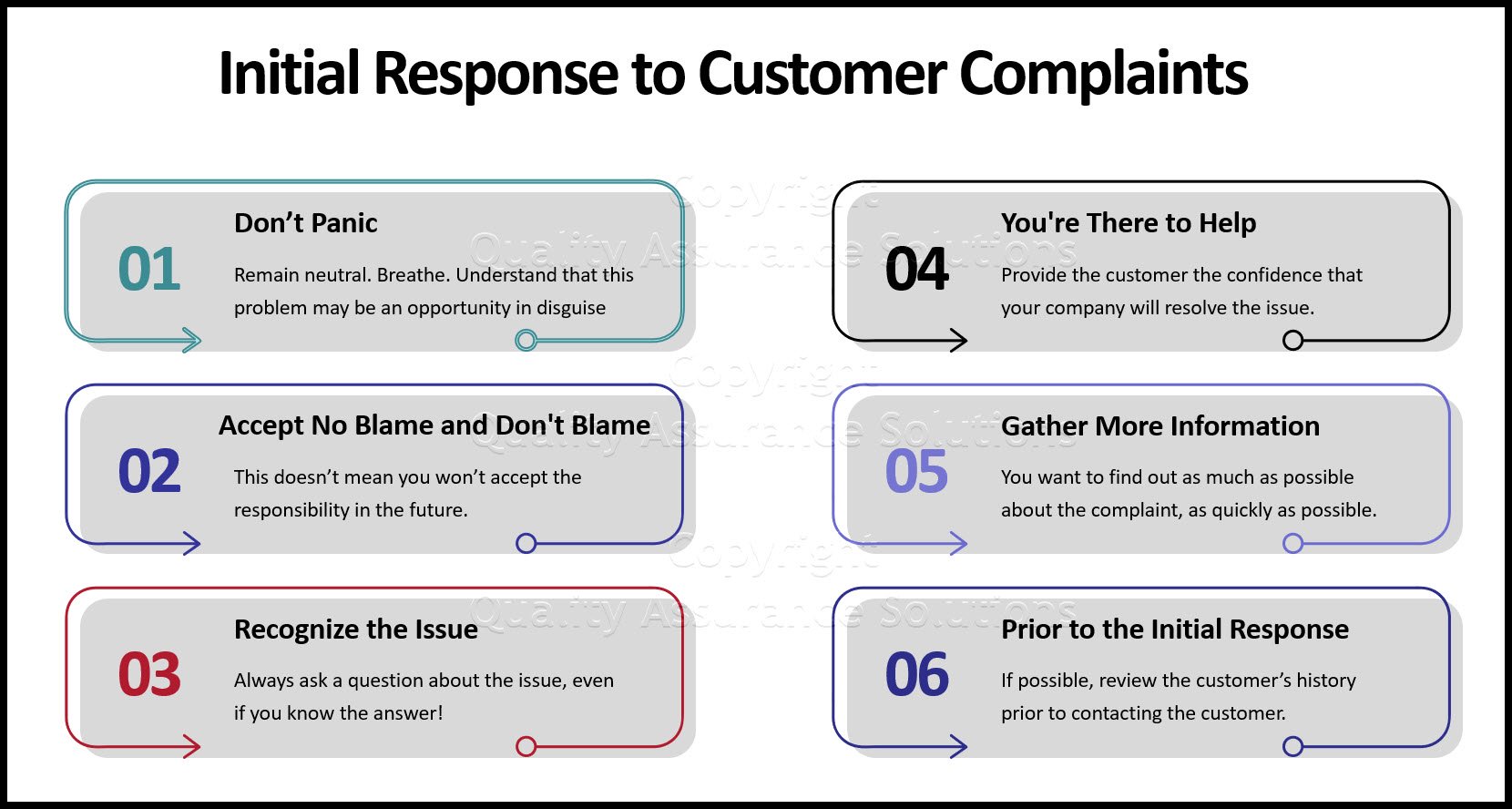

When your customers experience problems with your parts, they expect you to quickly address the issues. When dealing with these external issues, you need to deal with both your customer's external containment and your internal containment issues. You may find external containment difficult, costly and time consuming. As soon as your customer finds an issue, he immediately thinks more defects will appear. How many parts have this problem? What is the defect rate? Do similar parts have the same problem? How prevalent is this issue?

During your external containment theory analysis, help your customer as much as possible. Provide information without being asked upon. If the customer needs to push you, then you are not taking appropriate action.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

If you have excellent traceability, provide the suspect lot numbers to the customer. With these lot numbers your customer can easily segregate the poor parts.

You may have to immediately replace the parts. Issue an RMA (Return Material Authorization) for the suspect parts. Leave the RMA open for other suspect parts. Don’t be cheap and make the customer angrier, pay for the return of the parts. Have the parts Fed Ex to your attention.

If necessary, visit the customer and fix the problem. Do not wait on this decision. The quicker you take action the more satisfied your customer. External defects are costly and you must be willing to spend the money to address the issue.

You may decide to take a part back and repair it at your facility. Once the part arrives then repair it immediately. Remember your customer depends on your parts. Without that unit, your customer’s production could be affected and it could cost them business with their customer.

Or you may visit the customer to help sort the good ones from the bad ones. Why? because you were responsible for shipping the defective product. You are responsible for assuring your customer doesn't use the defective parts. By making them sort the suspect parts, you are angering the customer.

The key to external containment theory is speed. Do not wait to answer customer emails. Do not wait to take action. Do not wait to notify your senior management. Do not wait to do failure analysis. Do not wait to repair the unit.

If this is a safety issue, then bare no expense. If not handle swiftly, these issues quickly lead to lawsuits. Ugly lawsuits can put you out of business.

Don’t forget other customers that received the same material. If Customer X complains then you know customer Y will also complain.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Internal Containment Theory

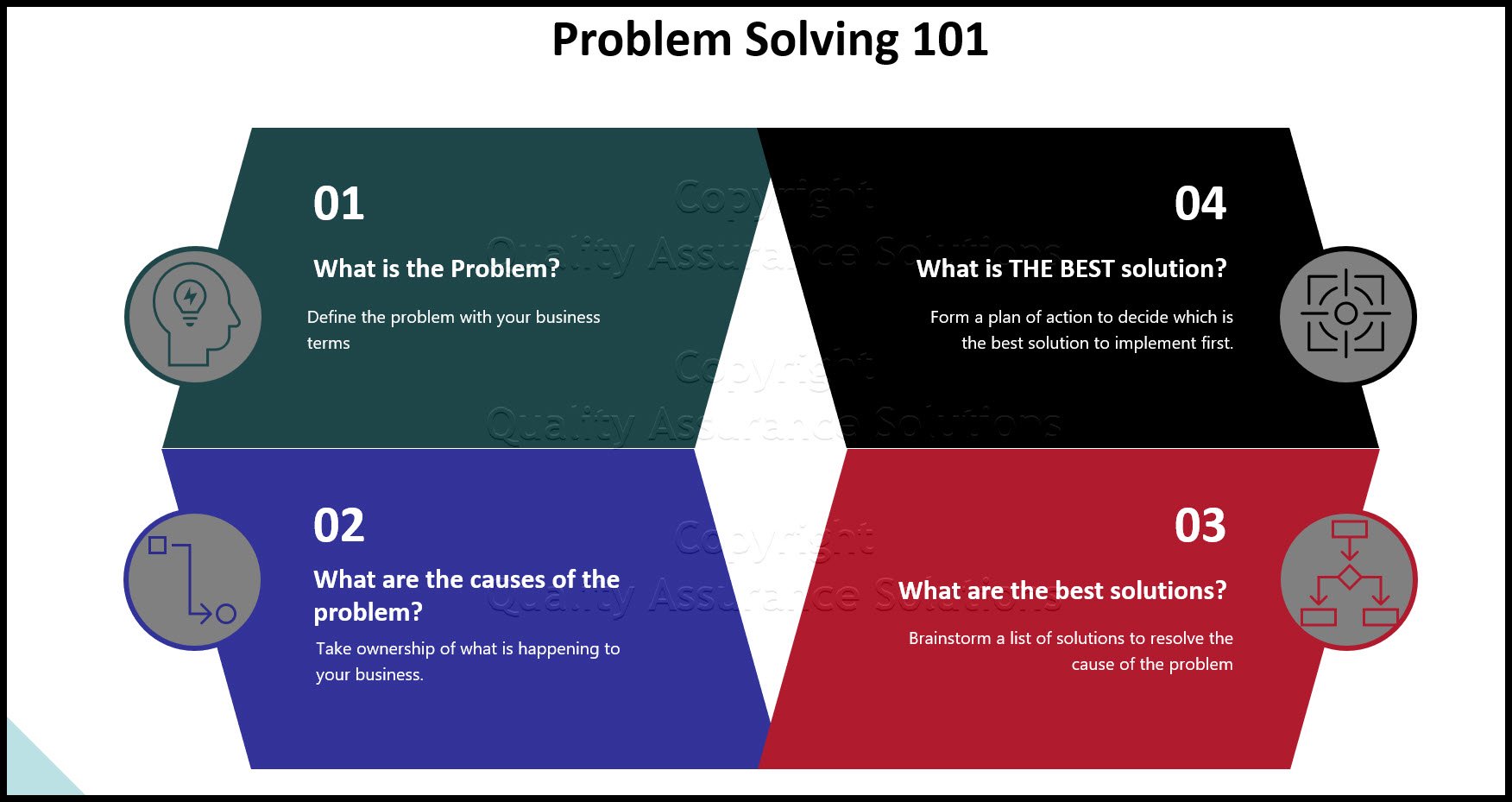

Internal containment is not as costly as external containment. When you find a problem with the product and it does not meet customer requirements then you need to take action. Most likely 100% sorting of the product will be necessary. This prevents the customer from receiving bad product. Do not let known defects escape. Escaping defects lead to external containment. As describe above this is very undesirable.

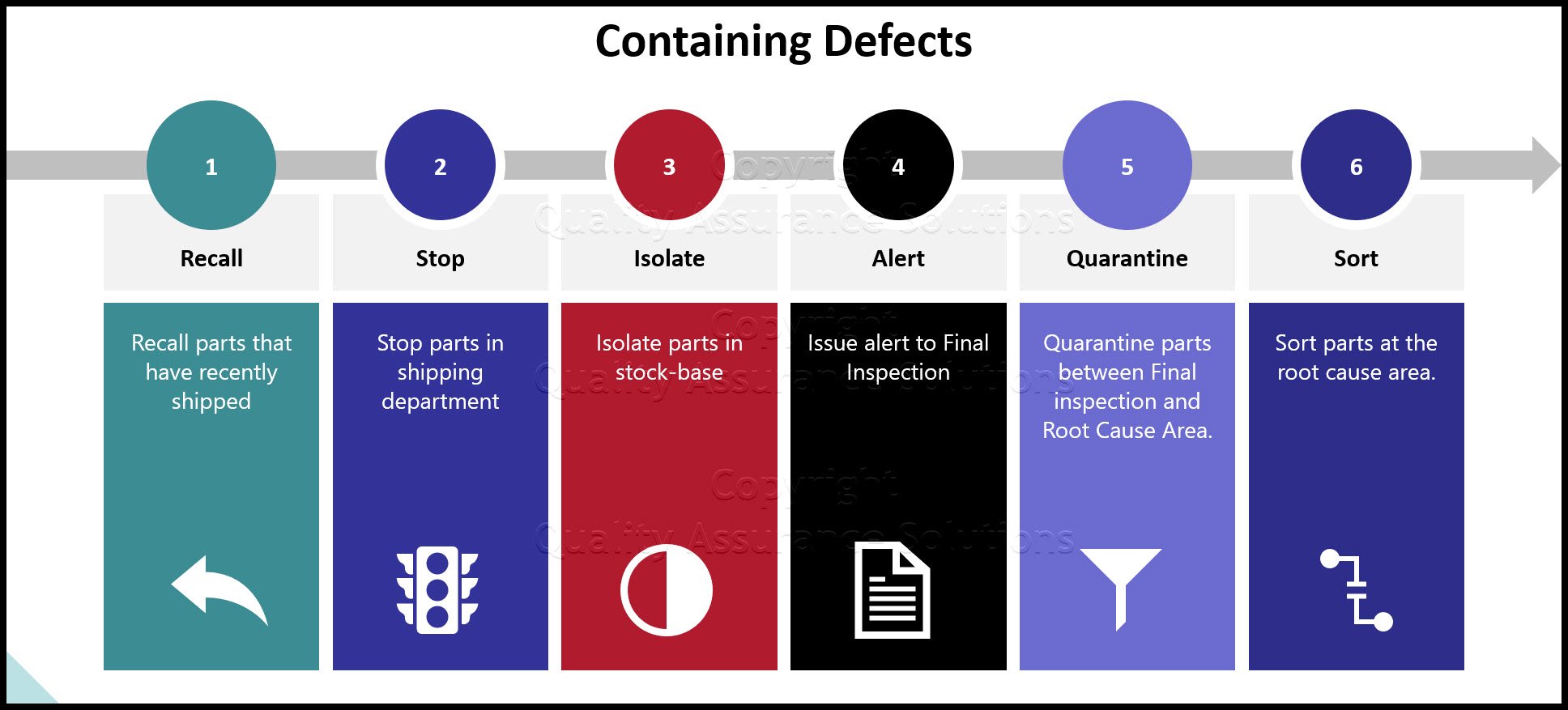

Internal containment actions start at the end of the process. Then move backwards to the root cause area.

- Recall parts that have recently shipped

- Stop parts in shipping department

- Isolate parts in stock-base

- Issue alert to Final Inspection

- Quarantine parts between Final inspection and Root Cause Area.

- Sort parts at the root cause area.

If necessary, issue emergency containment documentation with pictures of the defects. Provide training to the employees on the documentation.

Evaluate similar products. They may have the same problem. Apply the same internal containment theory.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Warranty Issues

What happens when your customer finds a defect after your written warranty period? If it doesn’t involve a safety issue, then you most likely you are not liable. However, you need to sympathize with your customer. Don’t throw the warranty clause in your customer face and ignore their issue.

Explain the issue to your customer so they better understand the reason behind the warranty. Also let your customer know that their defect information helps you improve your product. Further, let them know you understand the issue and you are working on reducing the defect.

Finally, follow the internal containment theory to assure you are not shipping new product with the same issue.

- QAS Home

- 8D Reports

- Containment Theory

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |