Benchmarking Definition

and

Benchmarking Best Practices

According to ASQ, the benchmarking definition in business is the process of measuring products, services, and processes against those of organizations known to be leaders in one or more aspects of their operations. Benchmarking provides necessary insights to help you understand how your organization compares with similar organizations, even if they are in a different business or have a different group of customers.

Per the above definition, some of the key elements to benchmarking include these ideas

- Measurement (need actual data)

- Leader (compare to the best)

- Insight (provides education to your business)

Shoe cobblers originally created the term benchmarking as it refers to them measuring people's feet for shoes. They would take the customer's foot and place it on a "bench". They then marked / outline the foot to make a pattern for thier shoes.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Benchmarking and Product Development

During product development, many companies use benchmarking best practices to create the new product. This includes collecting samples of the competitive products.

The engineers and product testers take the products and start recording traits. They collect and compare measurements, document features, determine specifications, analysis variation etc.

Prior to the benchmarking definition measurements, the benchmarking team creates a chart of features that need to be examined. This includes physical measurements, functions, characteristics, etc.

Benchmarking includes examining the competition from the customer’s point of view. During the benchmarking phase, you may need to change the chart as unknowns are discovered.

Benchmarking best practices includes surveying customers who actually use the products. The end user of the product determines the key characteristics.

Some traits may be hard to measure as they are personnal. In these cases the researchers try to put a quantitative number behind the ranking. They have the users rank the features on a scale such as 1 to 10

When you benchmark, you must document everything. After the documentation, review the numbers.

Most likely you find that there is not one competing product that is best in all things. During product development it’s critical to take the best features from the competing products and add your additional unique features to the new design.

Many times the desired features conflict with each other. When this occurs, consider weighing the importance of the feature by using customer input. List the features and have the customer rank them in the order of importance. Pareto the results and put engineering priority on meeting the pareto's top bars and then work down the list.

Comprehensive ISO 9001:2015 Audit Checklist for Internal, Gap and Certification Audits.

Benchmarking and Business Realignment

Businesses use the benchmarking definition in management for strategic planning. In this case management compares their overall business with leaders within their market segment. In this day and age this is easier then the past.

Many companies discuss their business model on-line. Employees within industries can openly and quickly communicate with each other. Customers of given products share known best practices with their suppliers. Also, customers have quicker access to technical support. Companies that practice sound benchmarking, review this feedback and act upon it.

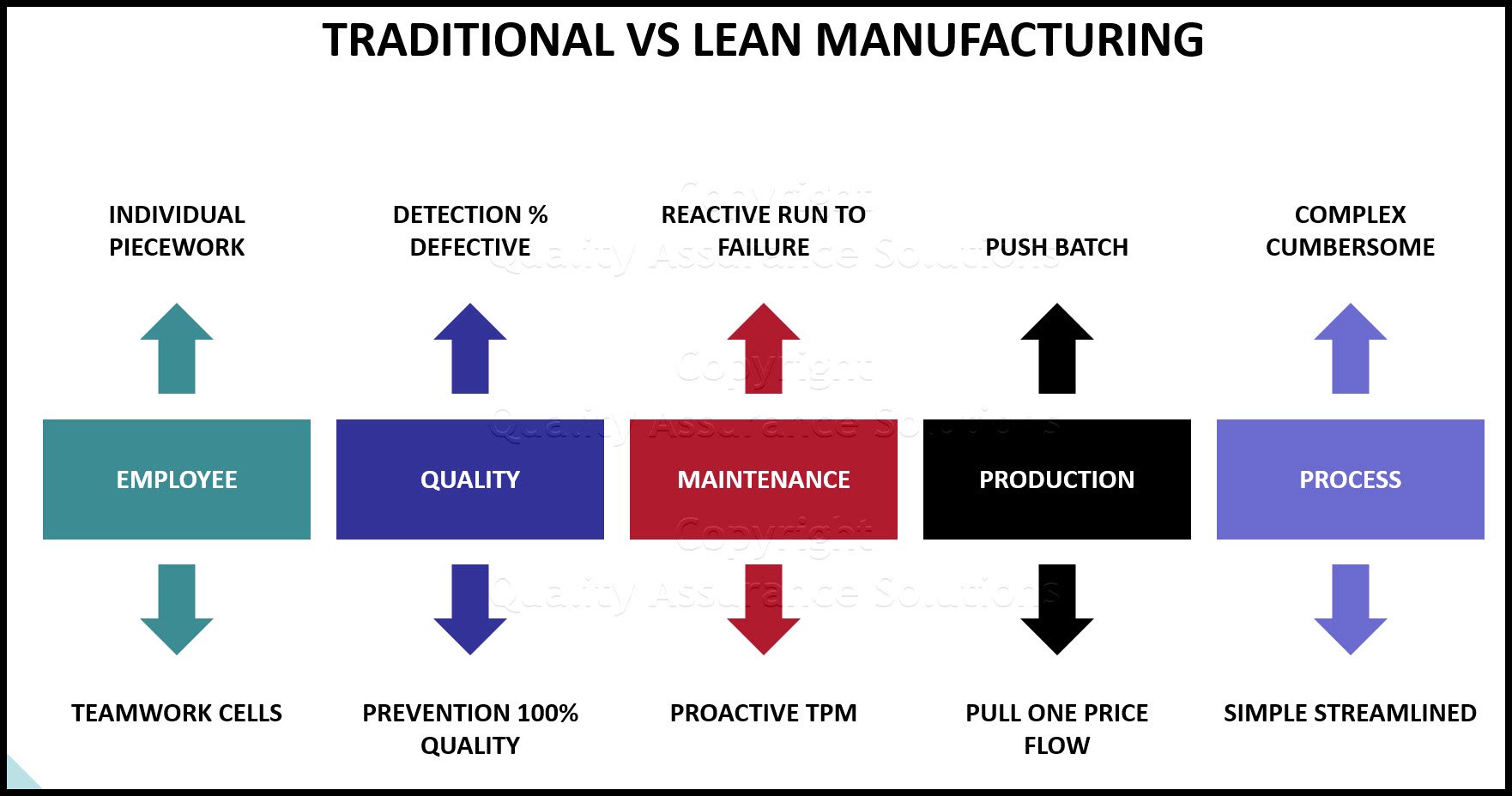

This ease of communication and acting upon benchmarking data makes benchmarking best practices difficult too. Why?, because best practices change very quickly. Although lean companies can implement today's best practices, it’s difficult to stay current because best practices change monthly, weekly and sometimes daily.

In addition, constant management system changes may interfere with the company’s core business. While employees learn and apply these best practice techniques, constant changes causes turmoil and employees may lose focus on the items that make the business money.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

Benchmarking Definition Internal Processes

If you’re starting with the benchmarking definition tool, start with internal processes. Here you can easily take advantages of benchmarking.

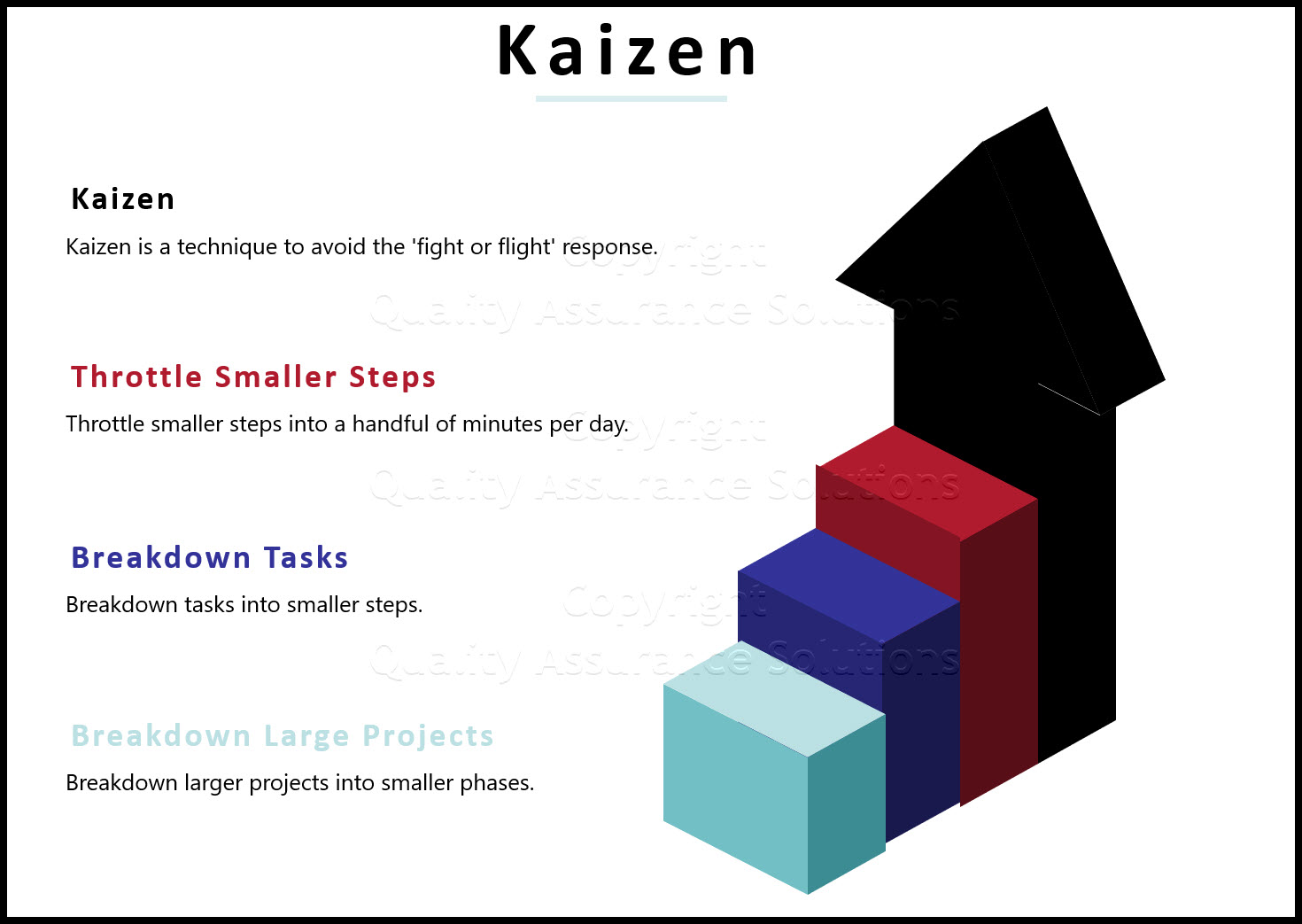

For example there may be a department that experienced success with applying kaizen and / or 5S. Have other departments benchmark this department. The studied department provides lessons learned, teaches possible pitfalls, and demonstrates the process. Someone from that department can lead other departments through their process improvement.

Large corporations can send teams to review and apply the benchmarking definition in business to their best divisions. It’s easier to do this then comparing to other companies because of the ease of access. Most companies don’t allow competitors to have on-site review of their processes. Large companies have this advantage because each division will run differently and use different methods to meet their goals.

Get certified in Risk Management through our completely on-line training system. Study at your own pace.

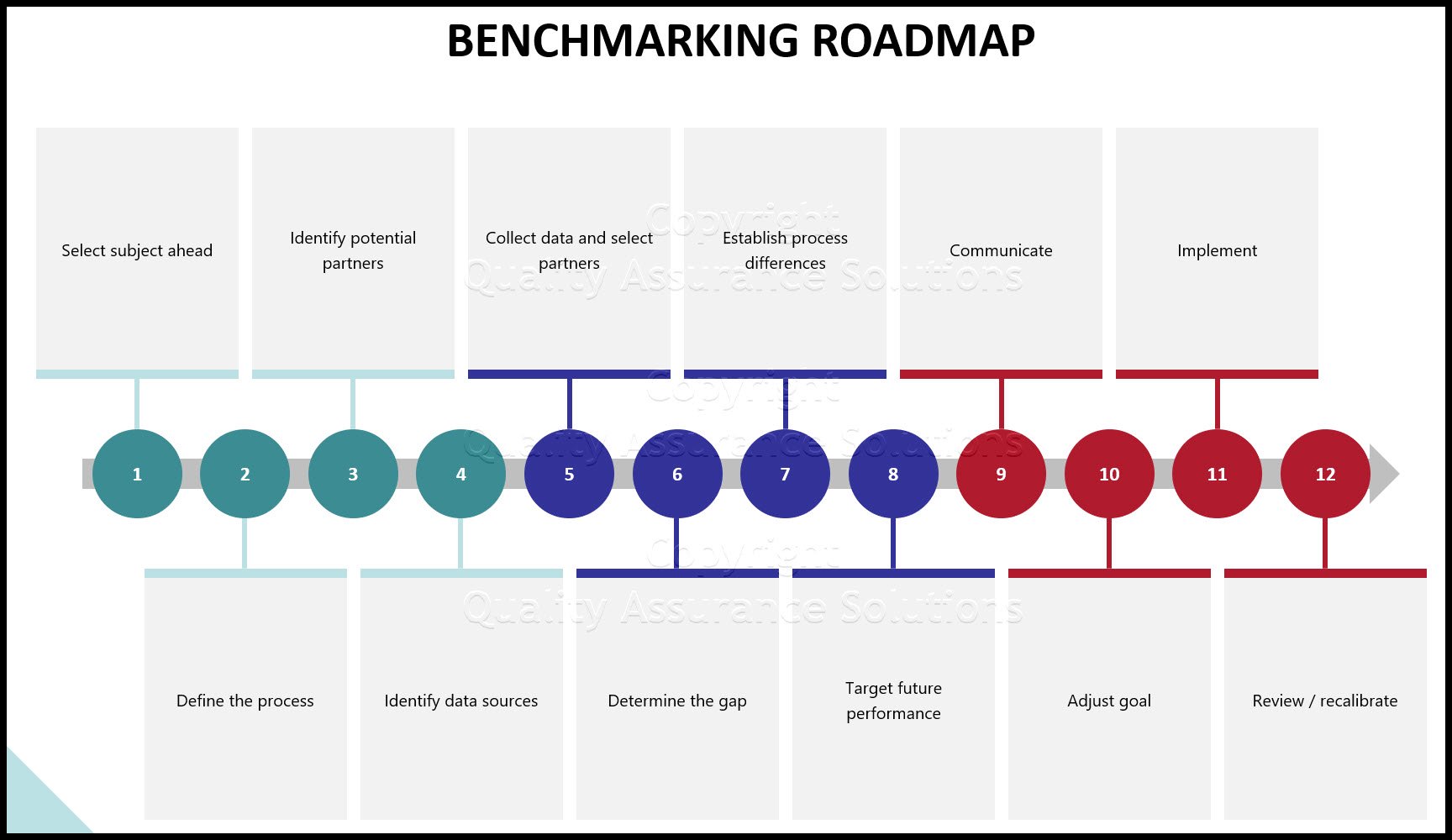

12 Stages of Benchmarking

- Select subject ahead

- Define the process

- Identify potential partners

- Identify data sources

- Collect data and select partners

- Determine the gap

- Establish process differences

- Target future performance

- Communicate

- Adjust goal

- Implement

- Review/recalibrate

- QAS Home

- Benchmarking

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |