The Level Mix Production Model

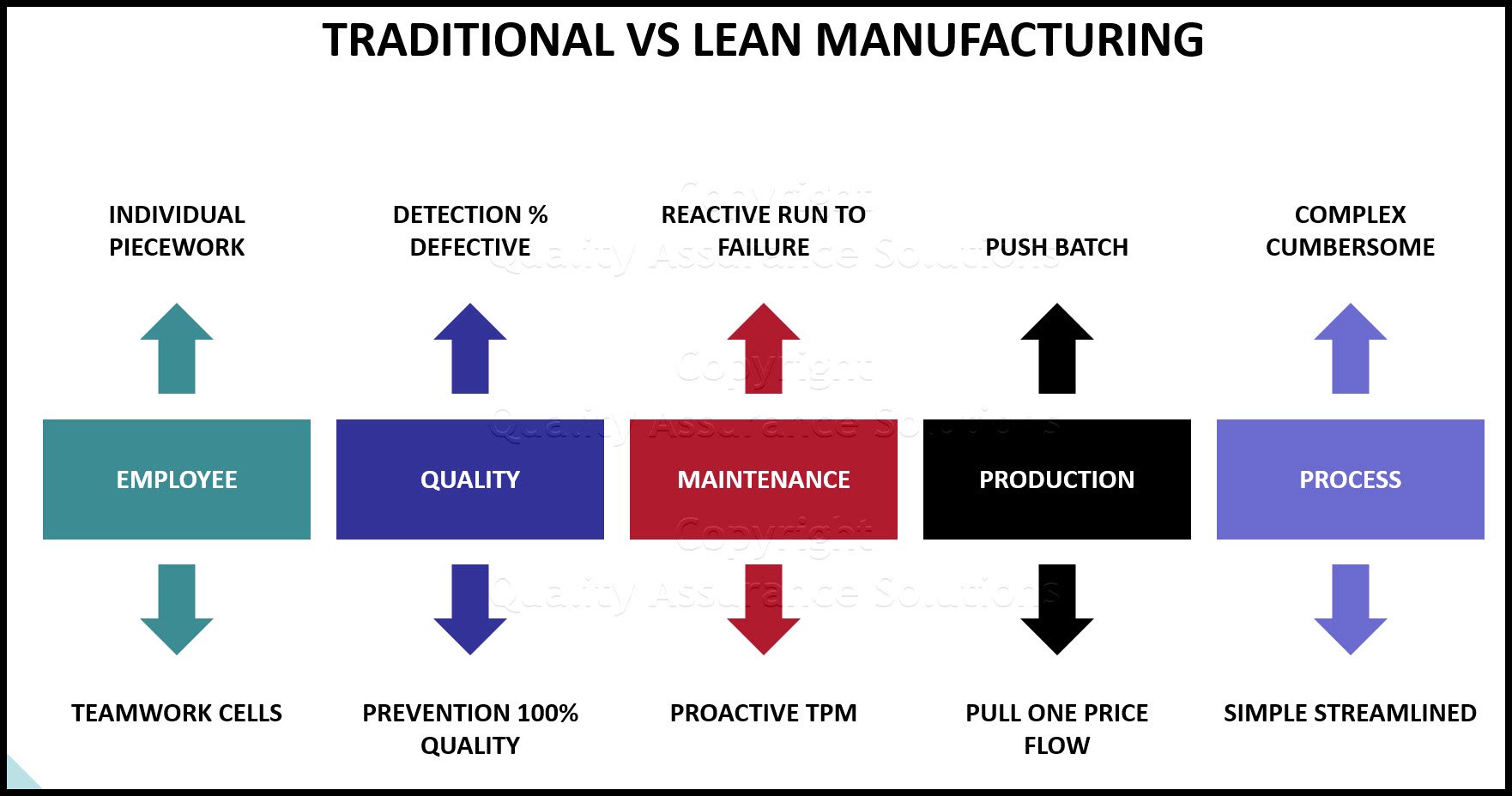

Level mix production schedules daily production of various types of products such that it evens out the peaks and valleys of those production quantities. Companies that achieve leveling mixing can respond to customer shifts in demand quantity and product mix.

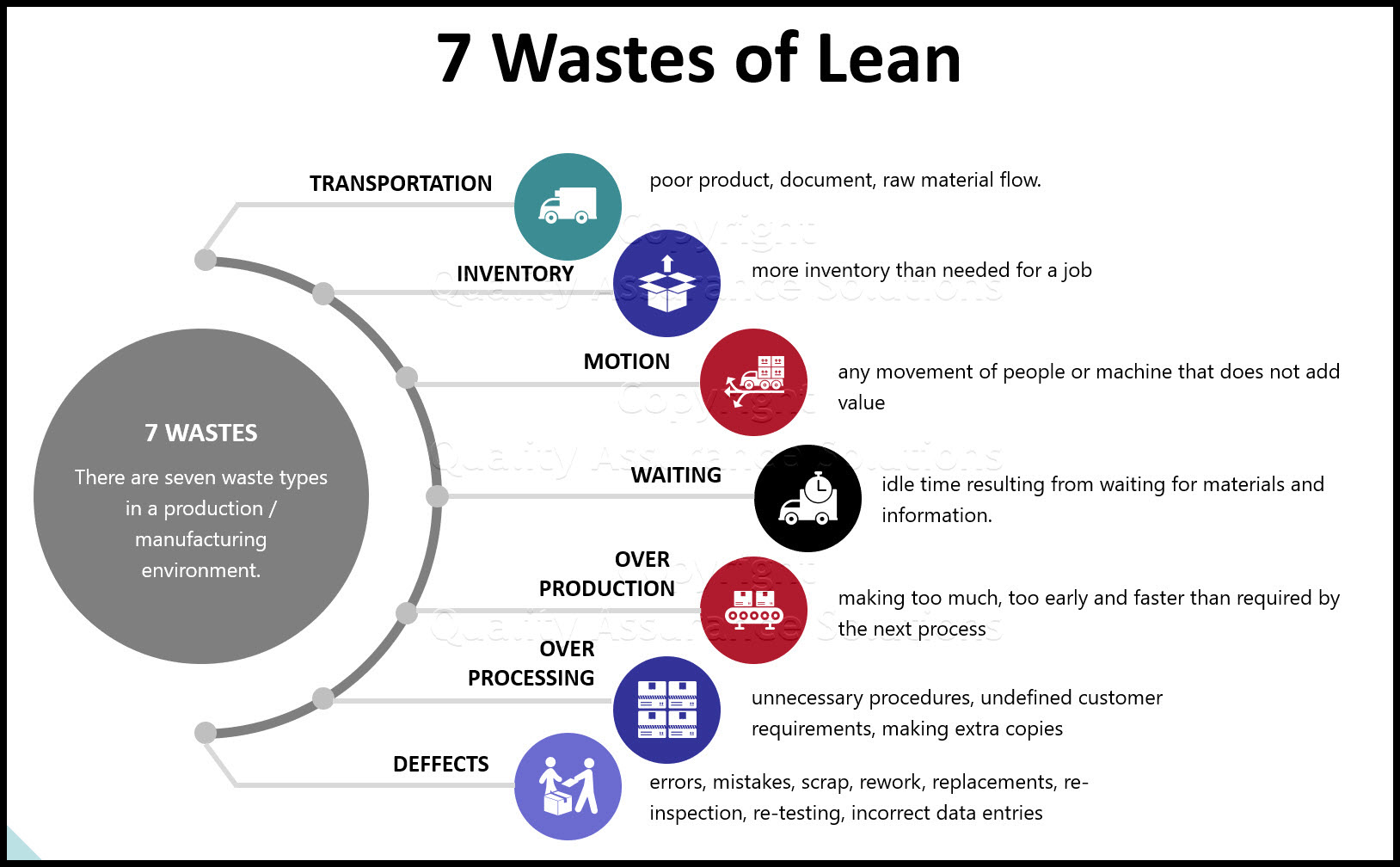

The existence of inventory at any process stage causes waste and ties up enterprise resources. This model allows the enterprise to build a variety of products demanded by customers in a smooth, repetitive, mixed sequence that minimizes inventory.

Example of Level Mix

During a week your customers order 500 of product A, 500 of product B, and 1,000 of product C. The level production would sequence those products to run in the progression A, C, B, C - A, C, B, C-, etc. The target would be to produce a total of 400 pieces per day over a five-day week. This levels the production requirements for the work cell.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

Lean

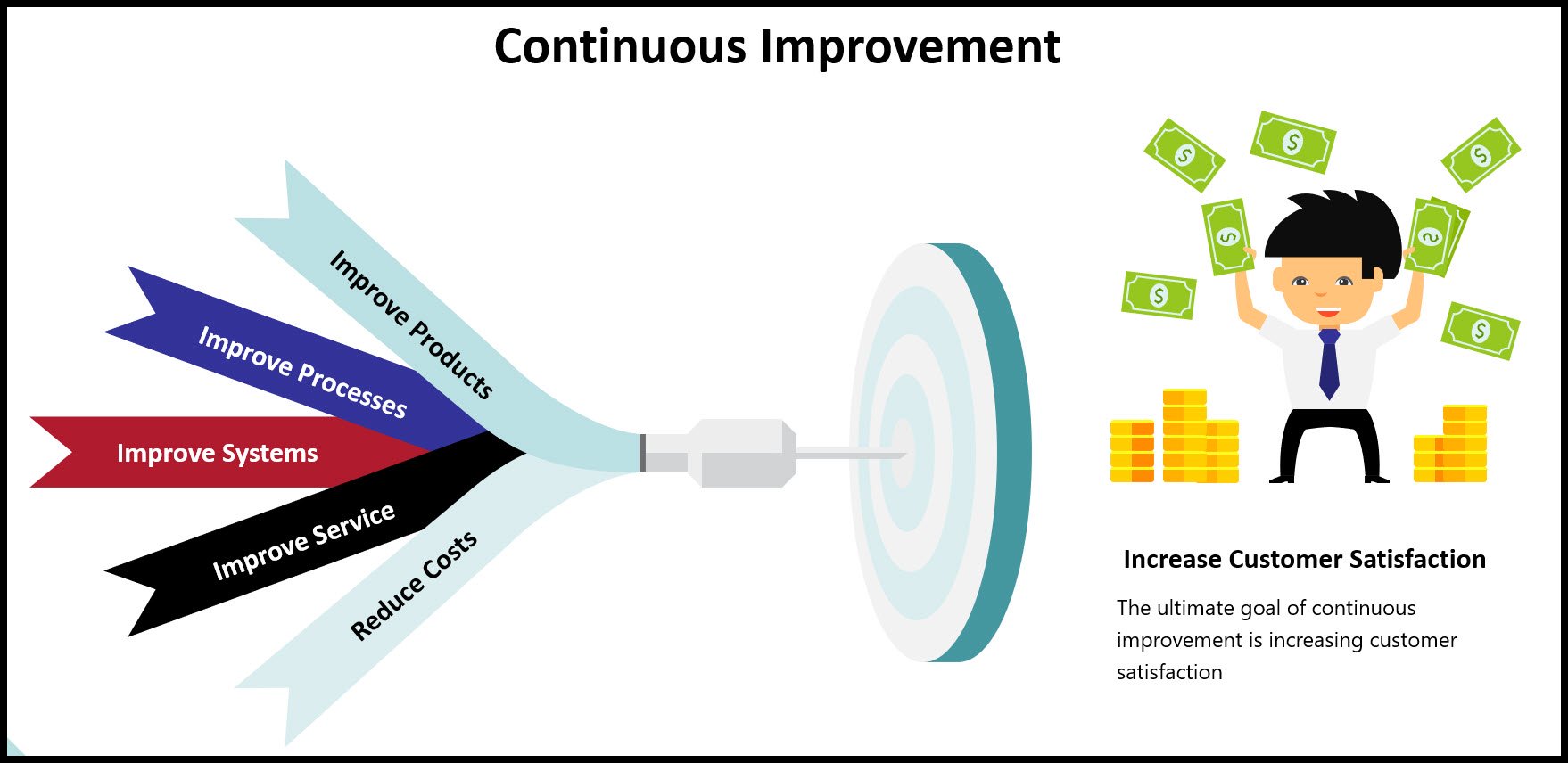

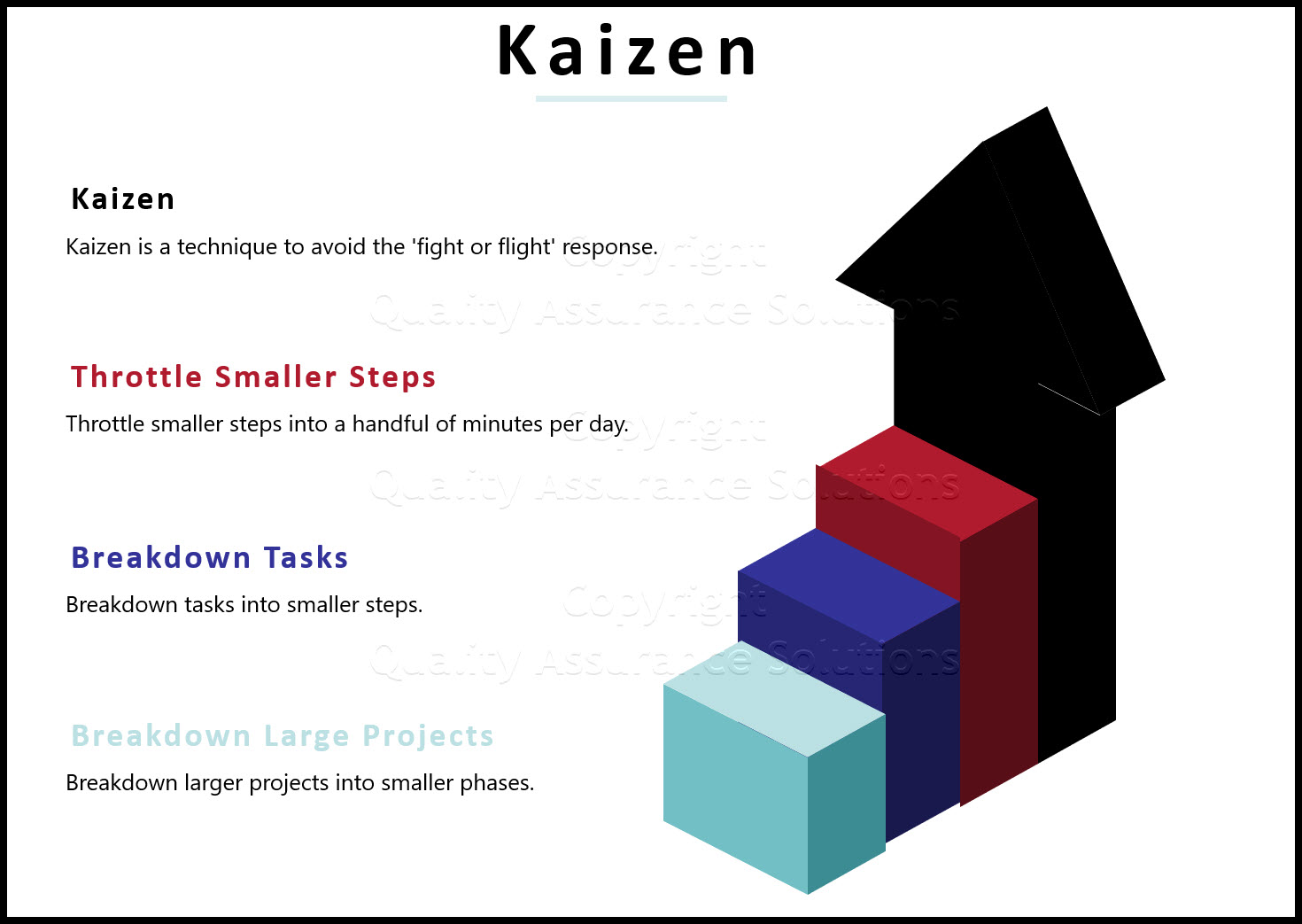

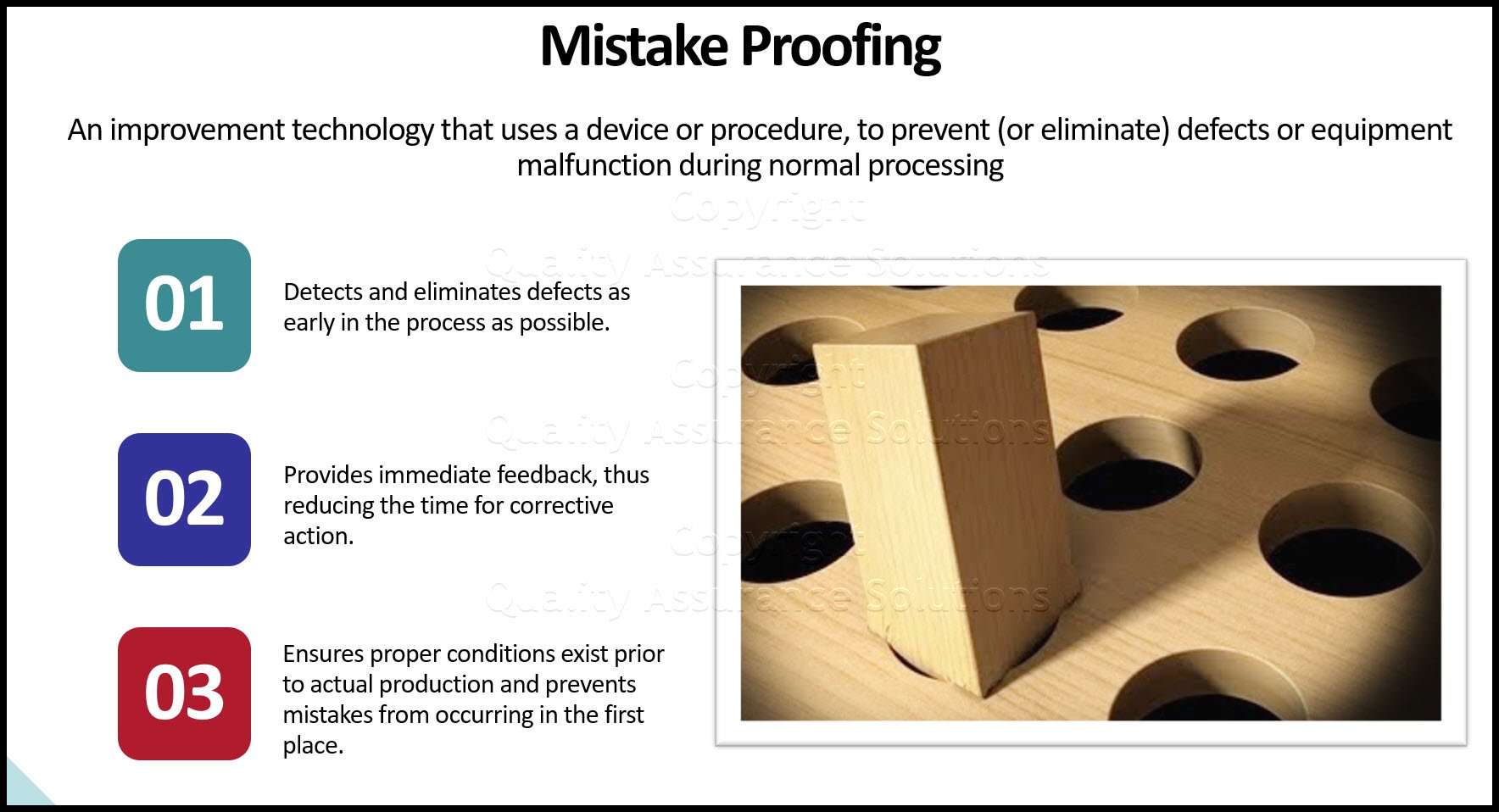

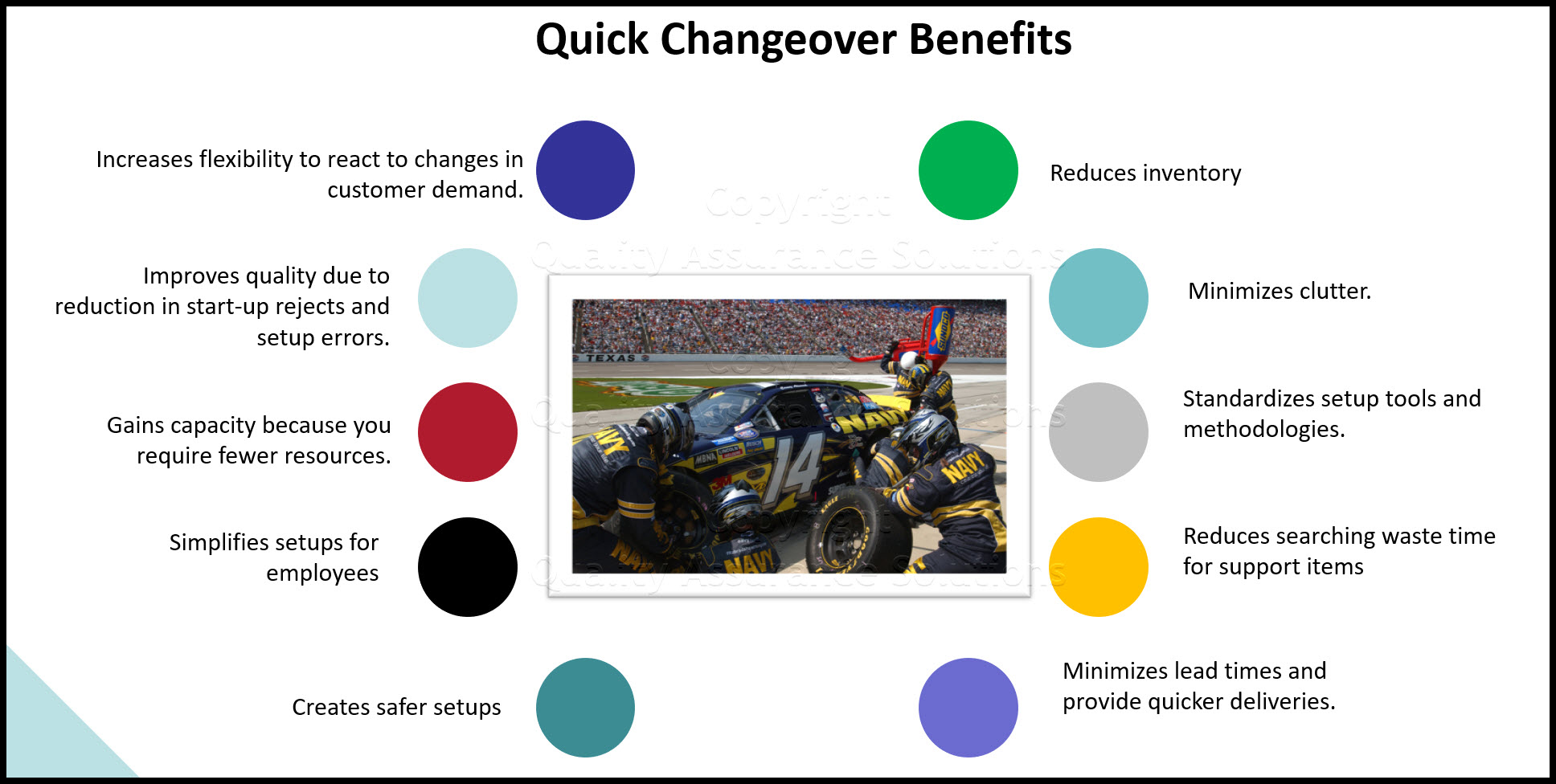

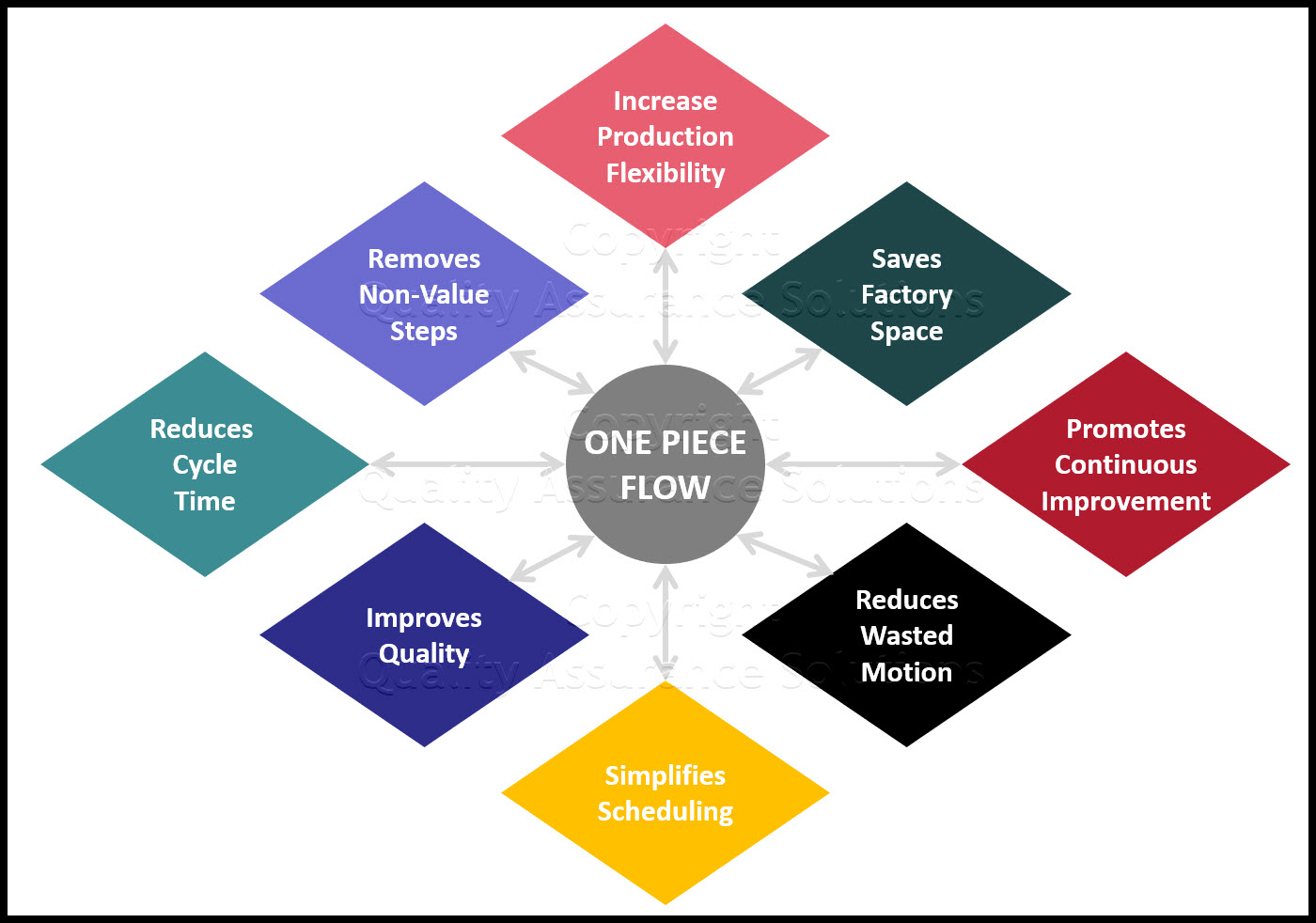

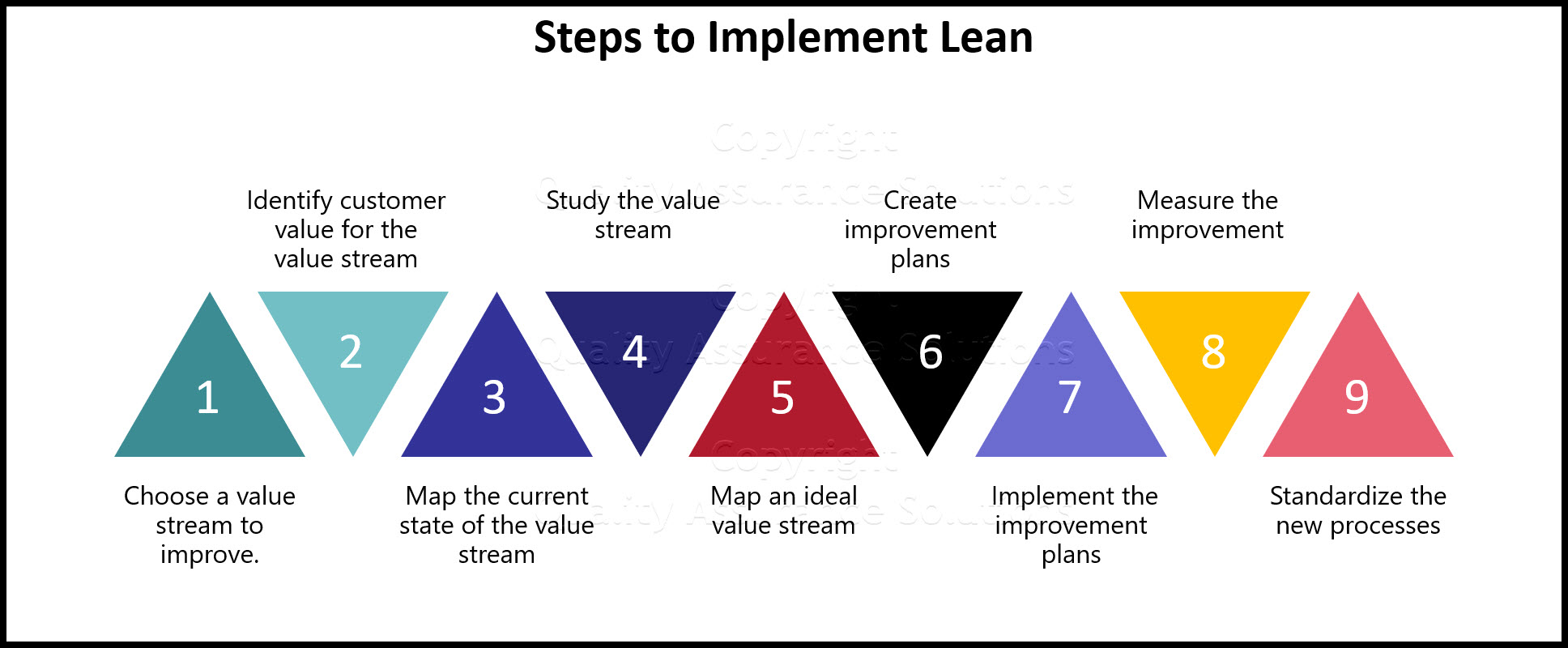

Leveling mix model production integrates with the lean tools of quick-changeover, kanban, mistake-proofing, 5S-visual management, standard-work, total productive maintenance, and one-piece-flow. Key objectives of the leveling mix model production are schedule attainment and production linearity.

Benefits

1) Transition from large lot production to small lot production.

2) Provides better distribution of inventory to meet customer demand.

3) Allows quicker response to market demand changes.

4) Supports kanban and one-piece flow production.

5) Reduction inventory for raw materials, subassemblies, finished goods, and work in process.

6) Improves performance for schedule linearity.

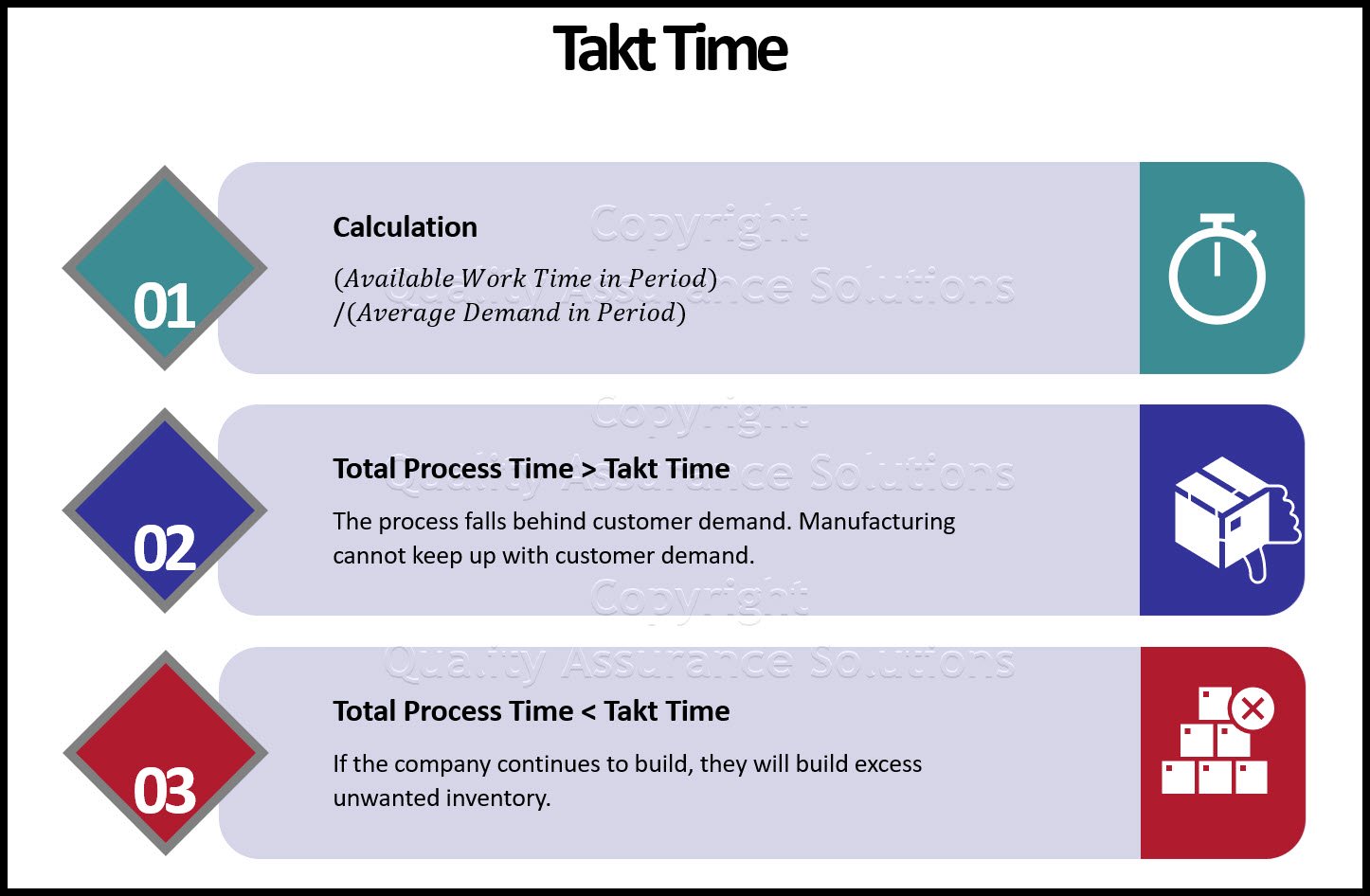

7) Provides linkage between cycle time of demand and cycle time of production.

8) Supports the ultimate objective to make small quantities of every product, every day, in ratios that match incoming demand.

9) Synchronized plant-wide daily production levels.

10) Improves return on assets.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |