One Piece Flow

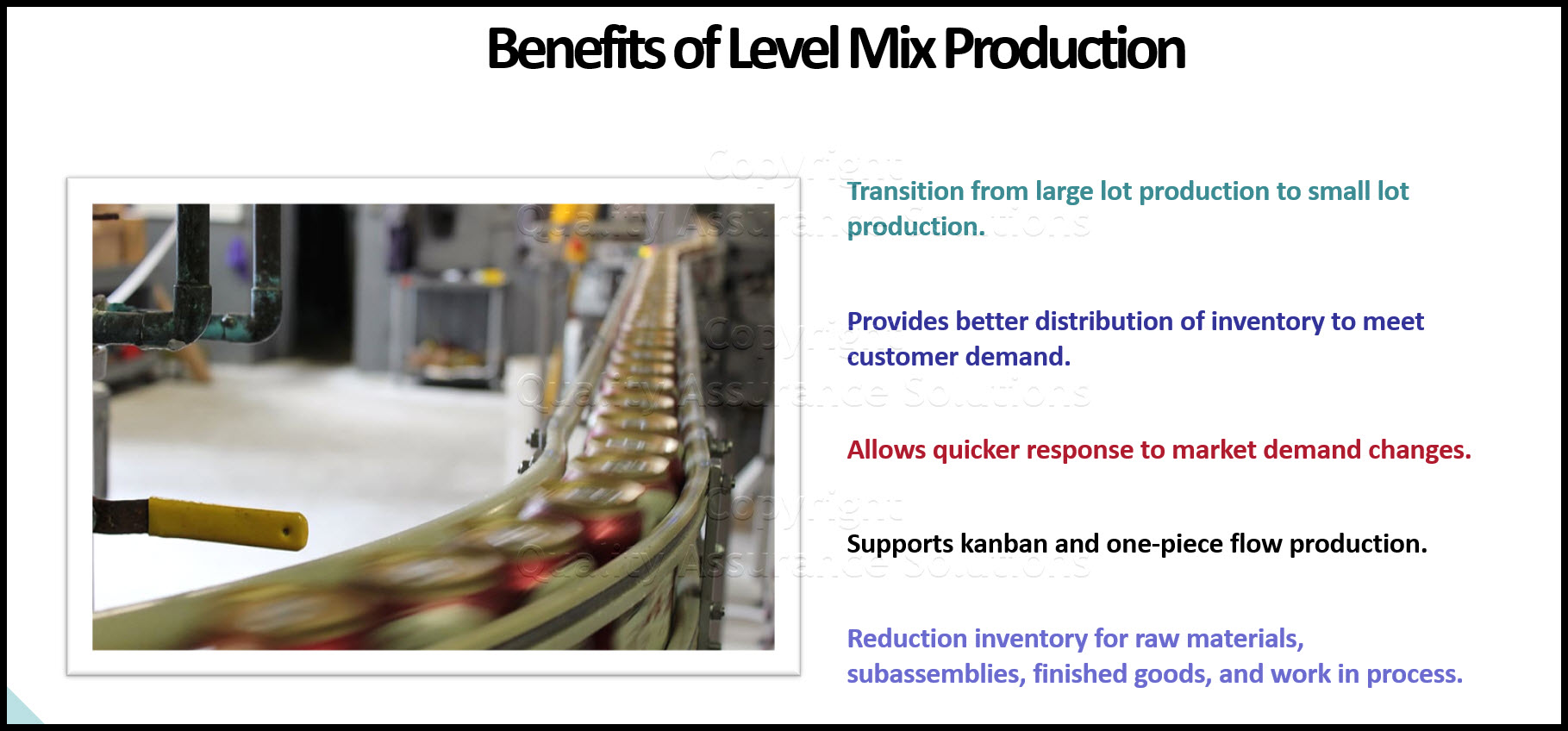

One piece flow means production of the product moves from one stage to the next stage one piece at a time. Compare that to lot production where several units are made at a given stage and then all are moved to the next stage at the same time. Most operational excellence practitioners promote one piece movement.

One piece movement benefits the manufacturer because there is no idle time between the units. With lot production the first piece made cannot move to the next step until the last piece in the lot is made. So that first piece sits idle.

One piece manufacturing also lets the producer stop the line quicker when a defect occurs. As soon as the defect occurs the manufacturing can stop production and fix the problem. The defect only occurs to that current unit. The next units should not see the defect because the manufacturer fix the problem immediately. This saves the manufacturer money.

With lot production, sampling inspection occurs after the production of a given step. If the inspection yields a defect then the entire lot is suspect. Each part in the lot needs to be reviewed for that defect. There may be more defects in the lot. Each defect adds to the total cost of the problem. When implemented properly, one piece flow prevents this additional costs.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

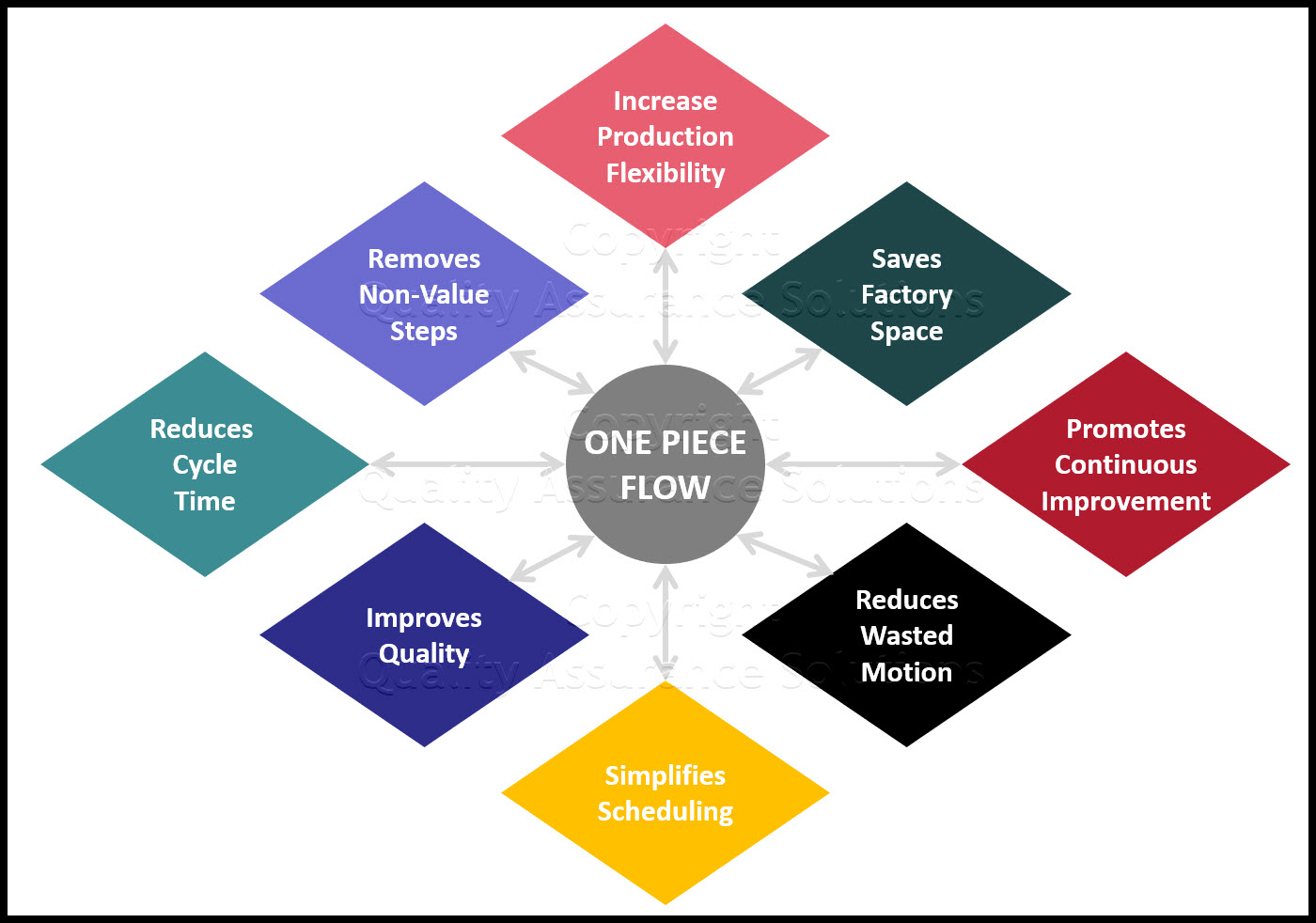

By Applying One Piece Flow You:

- Reduce throughput time and increases velocity for customer orders from order receipt through production and shipment.

- Improve value-added ratio through elimination of non-value-added activities which reduces operating costs.

- Allow the company higher degrees of flexibility to accommodate changes in customer demand.

- Save space in the factory.

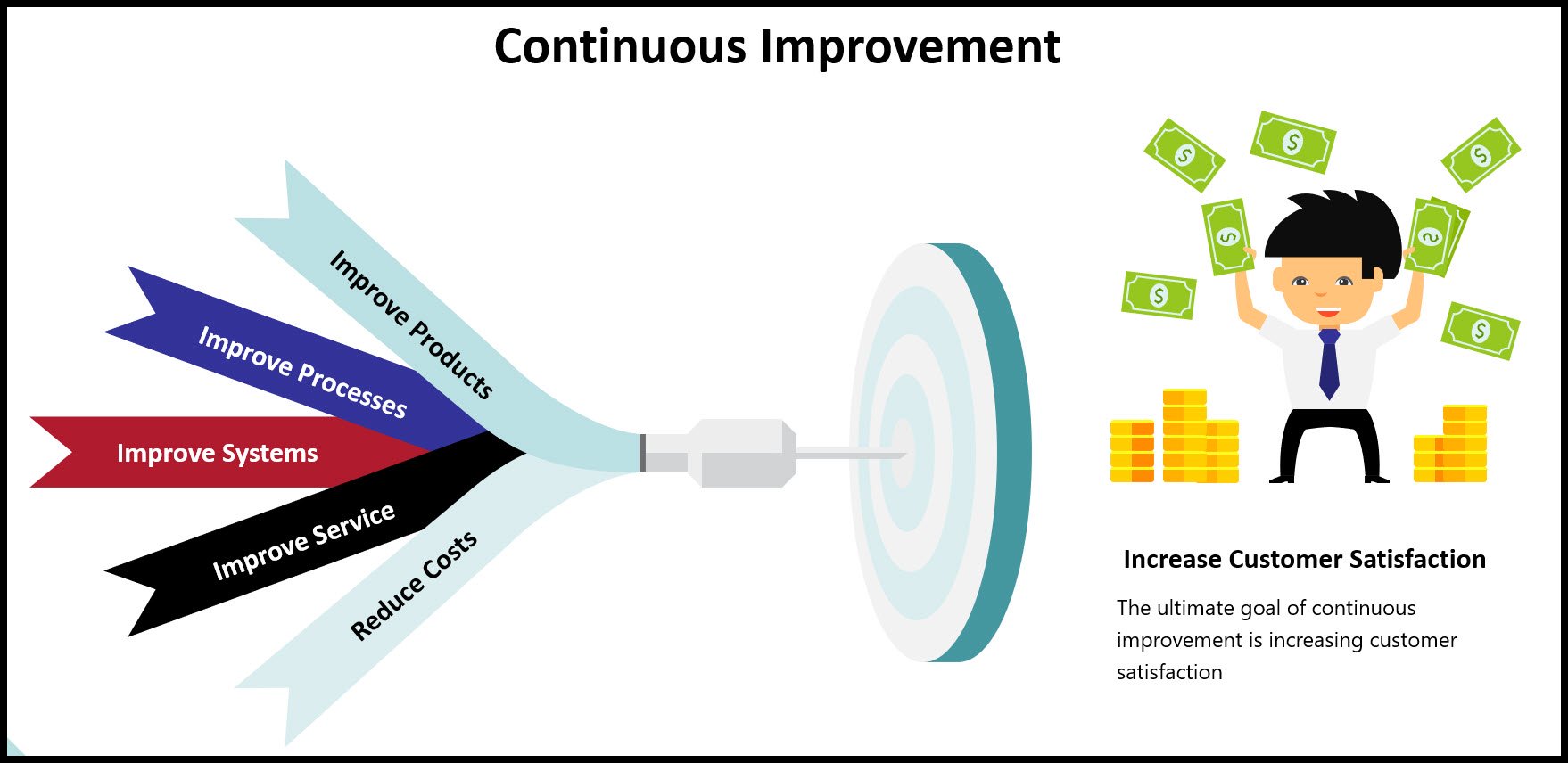

- Promote continuous improvement as problems are exposed.

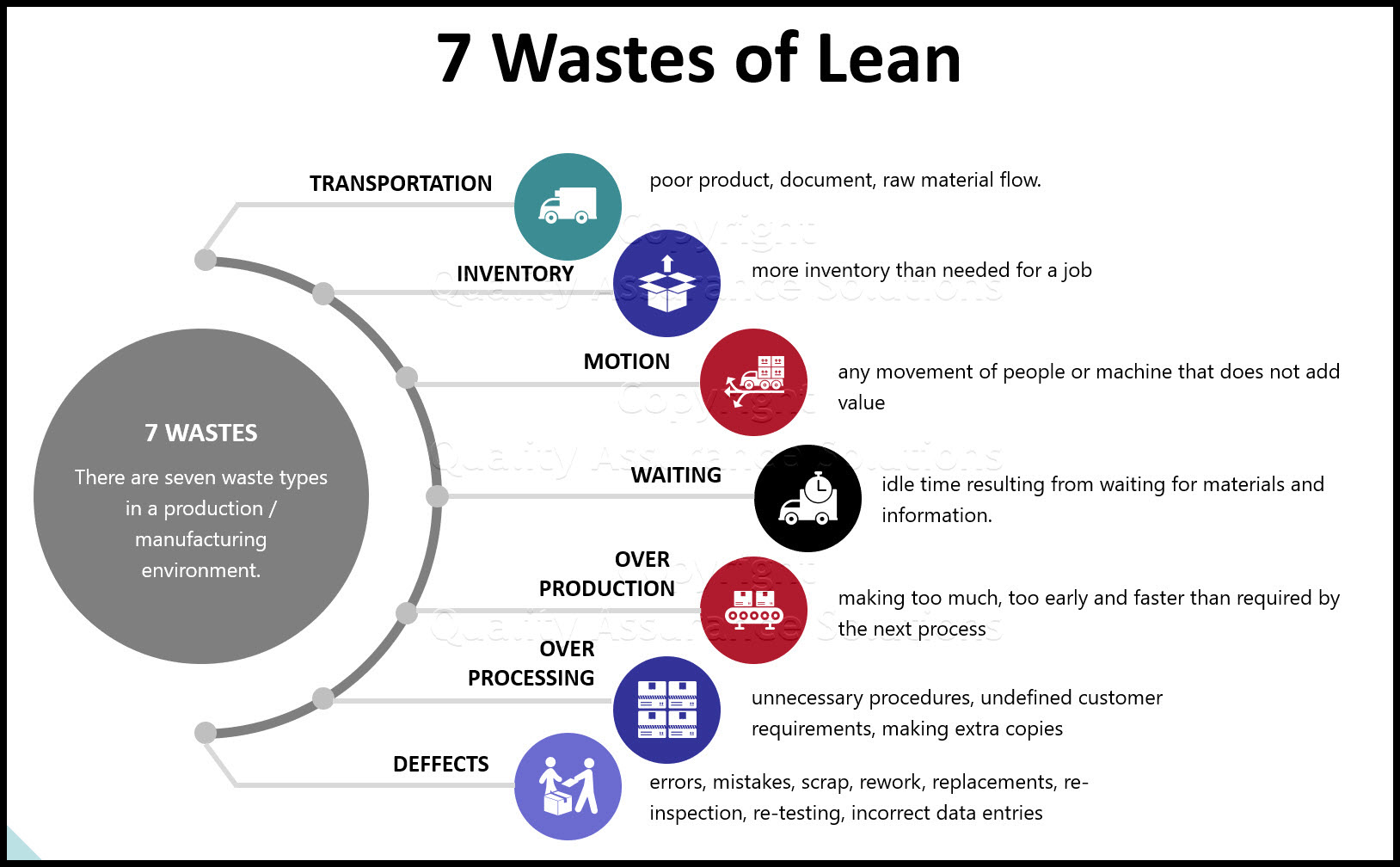

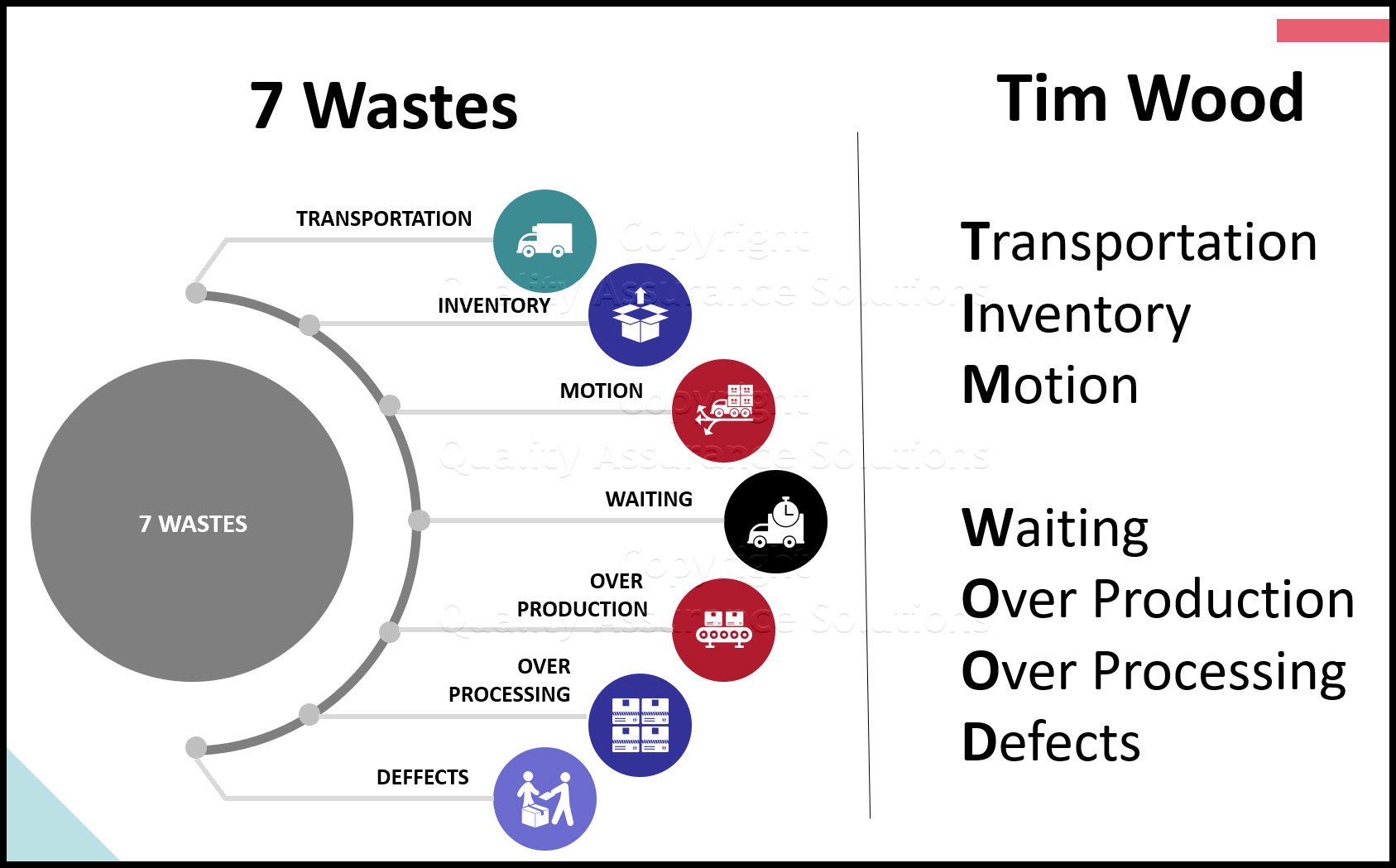

- Reduce transportation, waiting, overproduction, processing, inventory, and motion waste that occurs with batch processing.

- Lower the risks of product damage, deterioration, and obsolescence.

- Simplify scheduling.

- Support high-variety production.

- Reduce cycle time through increased production velocity.

- Support quality production.

Work Cells

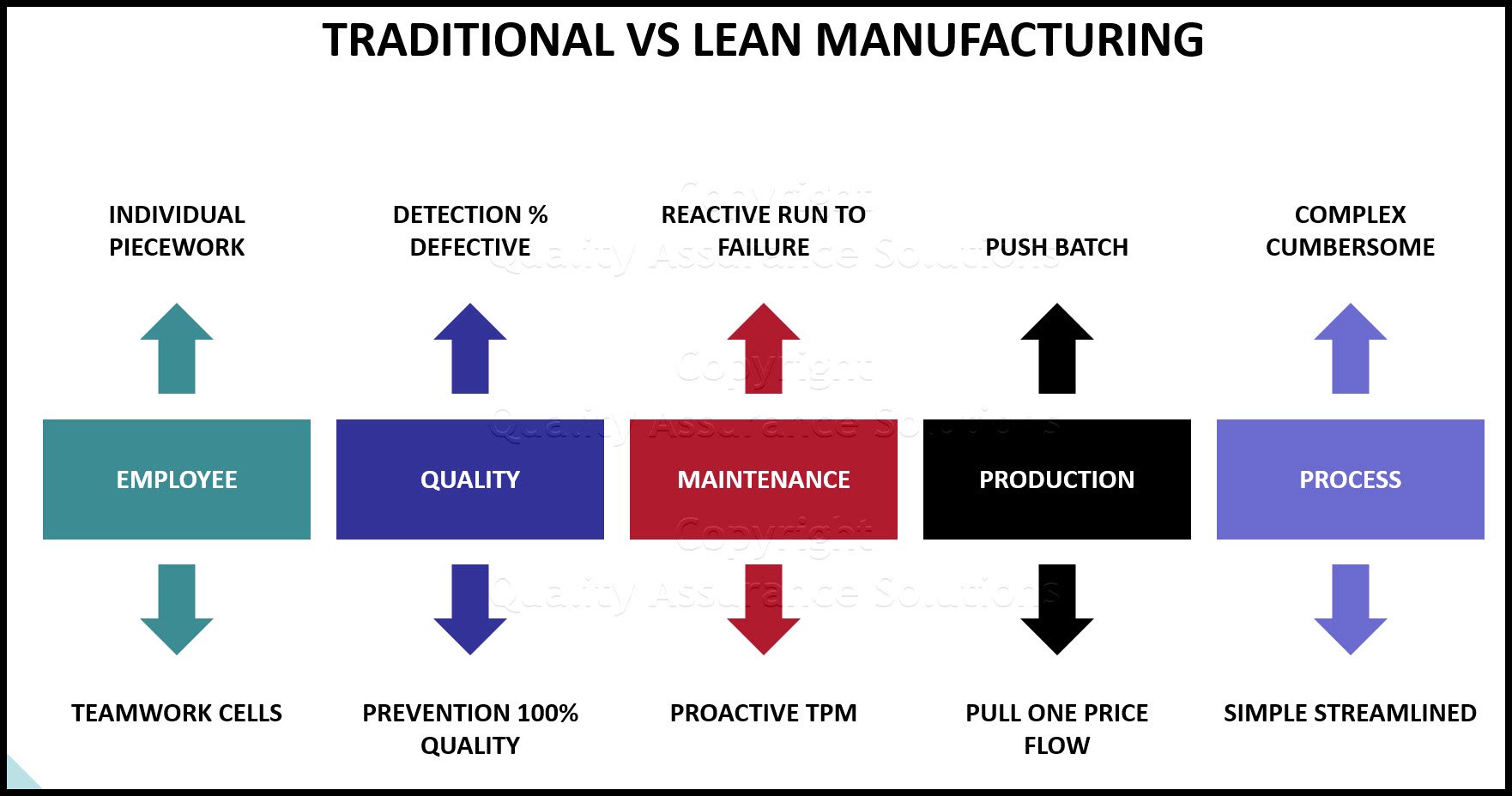

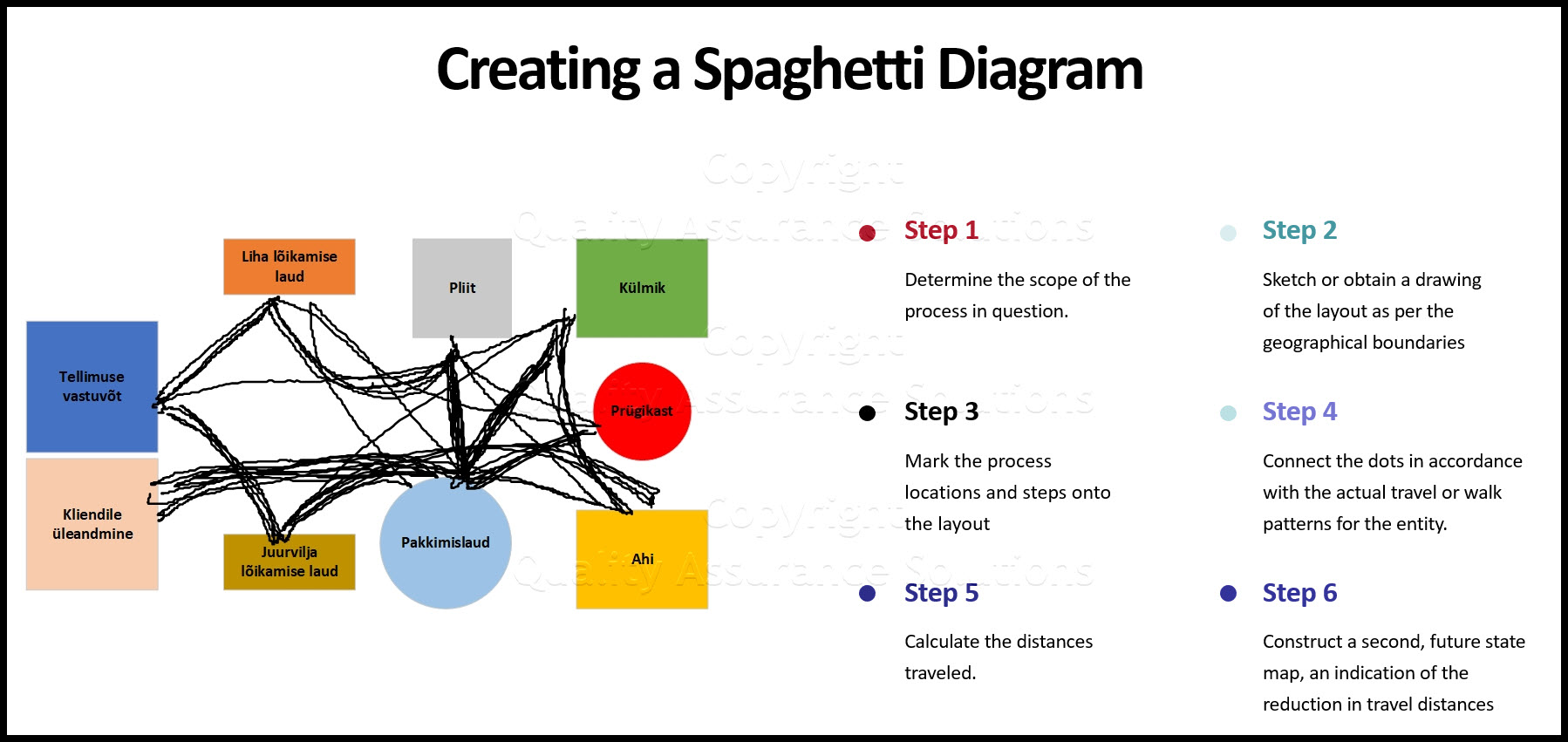

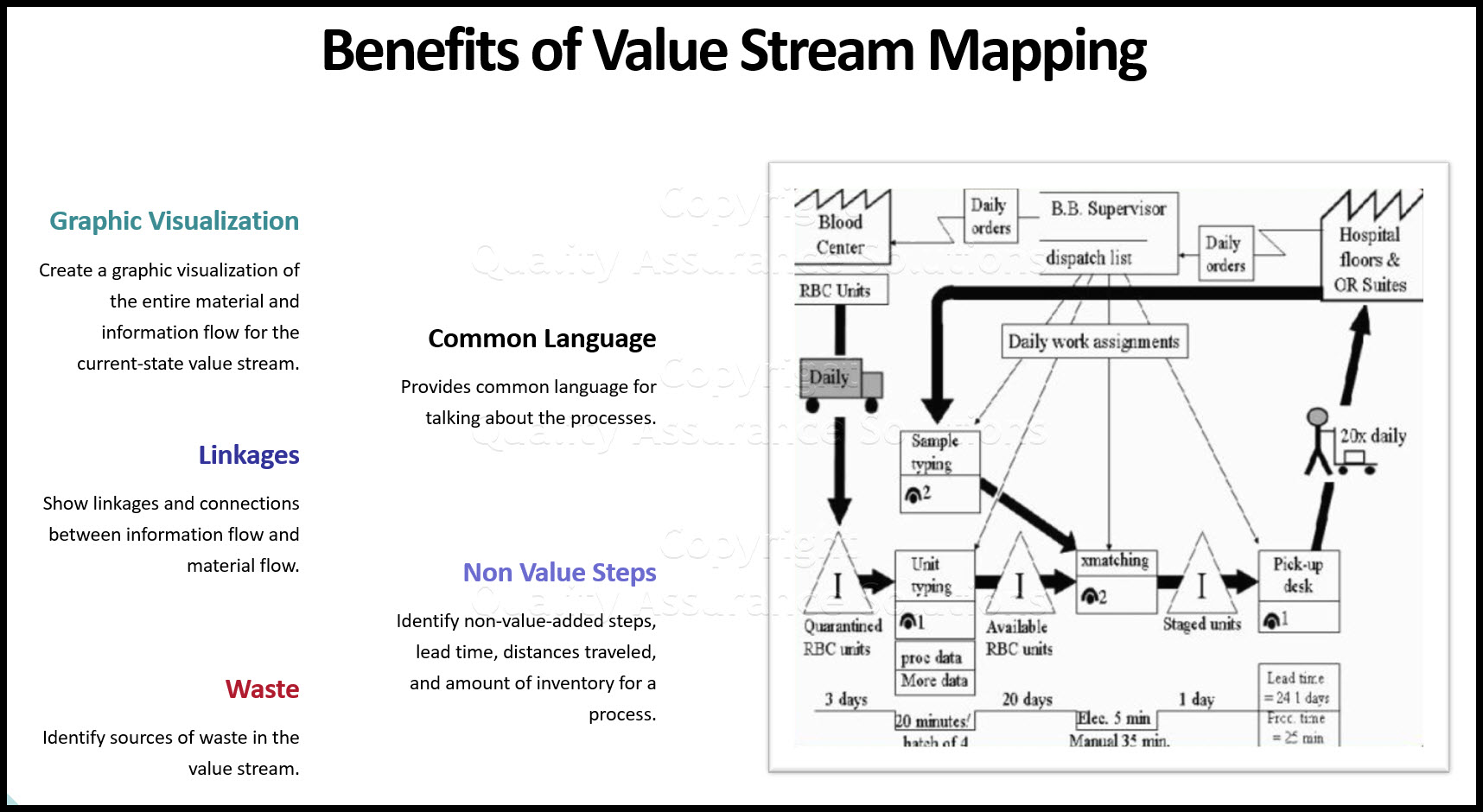

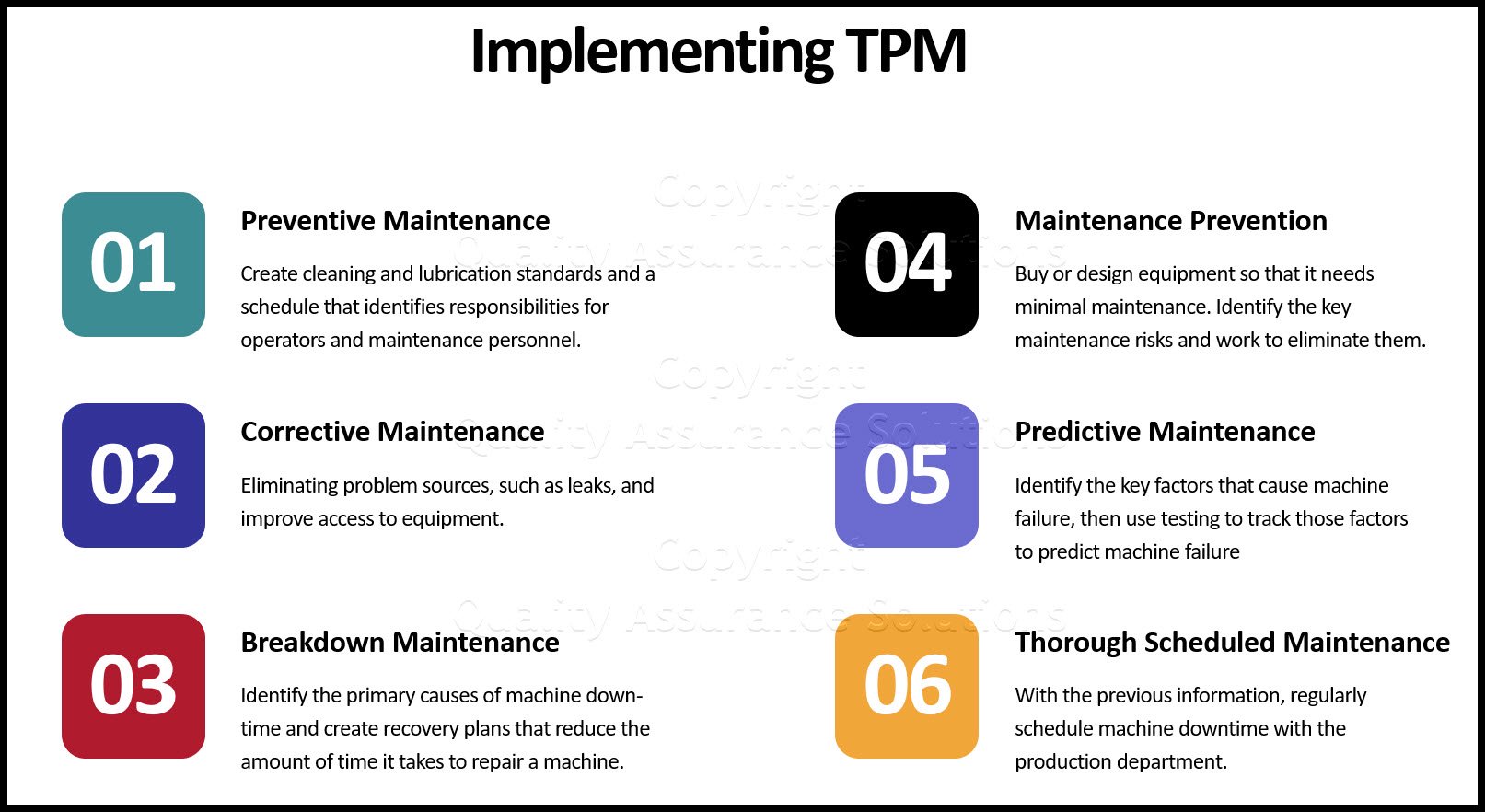

To implement one piece flow, connect and synchronize each individual activity process to eliminate the eight categories of waste. This requires improved layouts to minimize the travel distance between successive operations. In addition the company may implement work cells to implement one piece work flow.

Manufacturing departments in a traditional plant environment perform a specific task (i.e., grinding, welding, fabrication, drilling, assembly) utilizing workers who developed the single skill. Manufacturing cells, however, are designed to provide complete products to an internal work cell or an external customer. Work cells perform several operations or tasks and require multi-skilled, flexible workers.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Create and link U-shaped work cells to complete all process activities in the minimal amount of physical space. The principles of good work cell layout include arranging the work sequentially, using a counter clockwise flow, locating machines and processes close together, and locating the last operation close to the first operation.

Design the work cell to accomplish line balance with respect to takt time, and kanban triggers the authorization for production.

Work cell employees are responsible for the daily production of products to meet internal and external customer needs. The company empowers the cell employee to take all actions necessary to meet customer needs.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |