Root Cause

Corrective Action

System

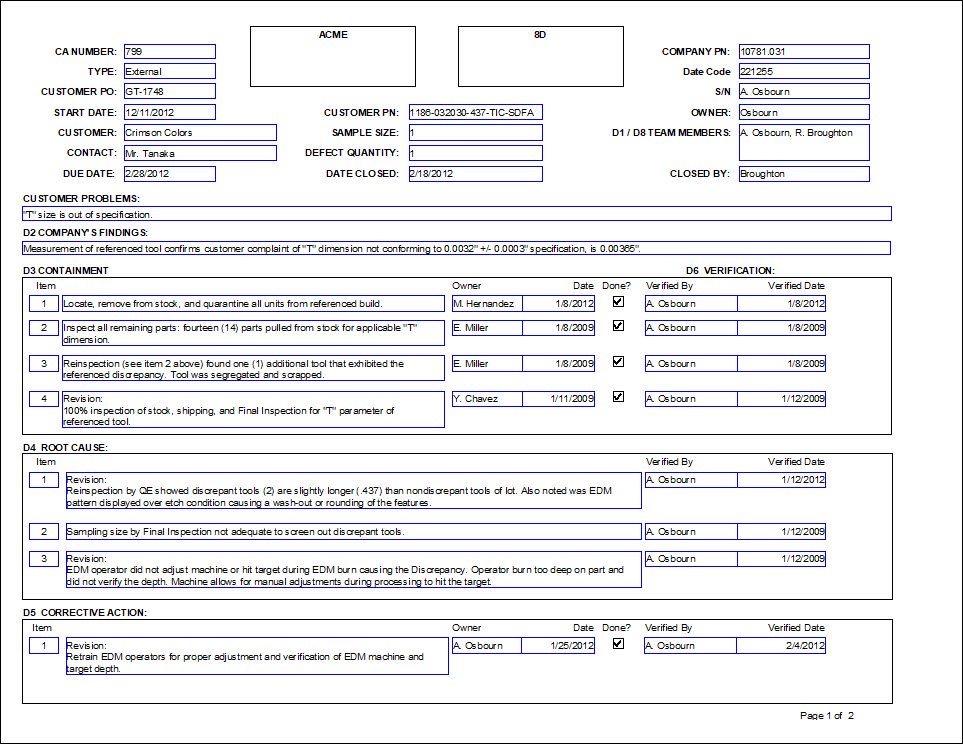

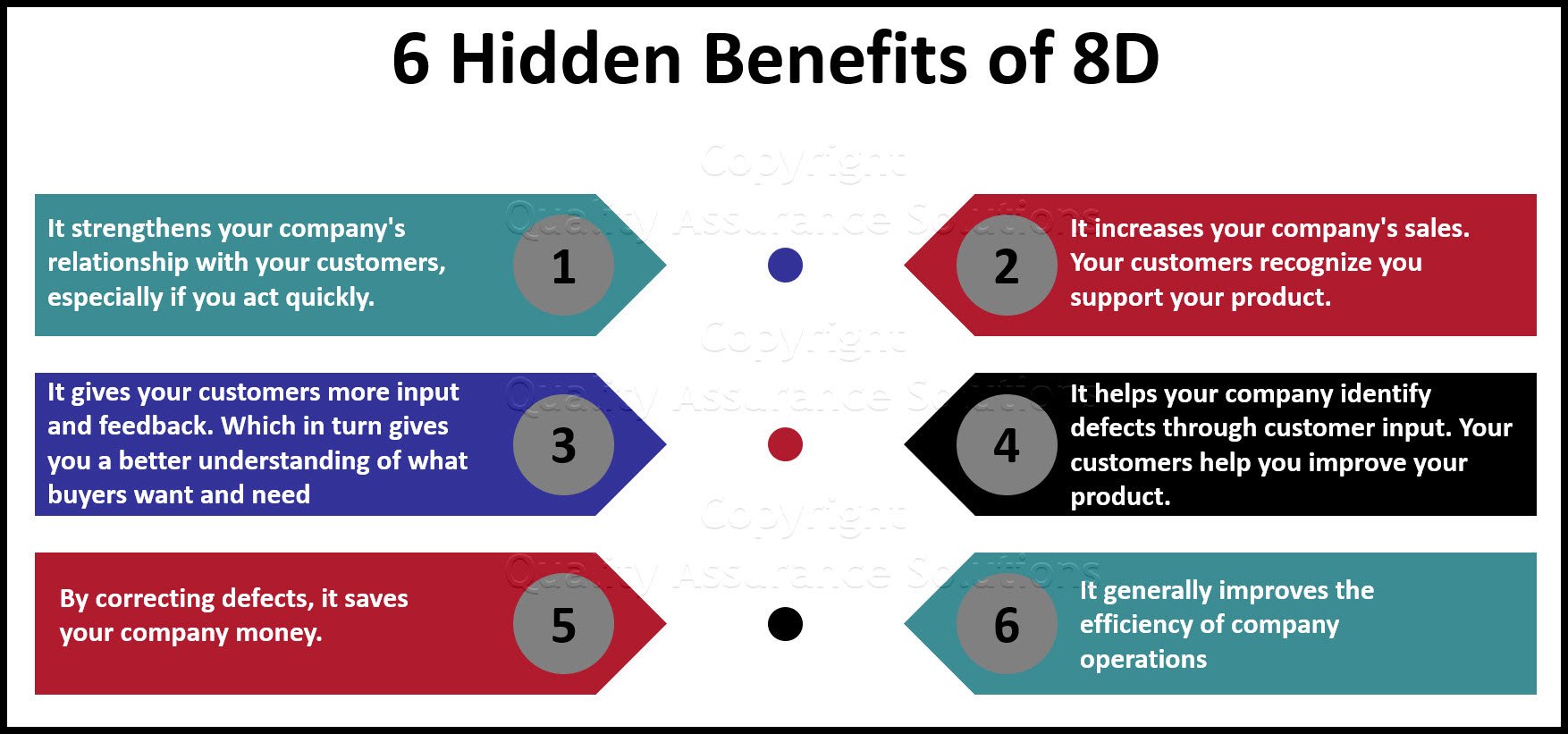

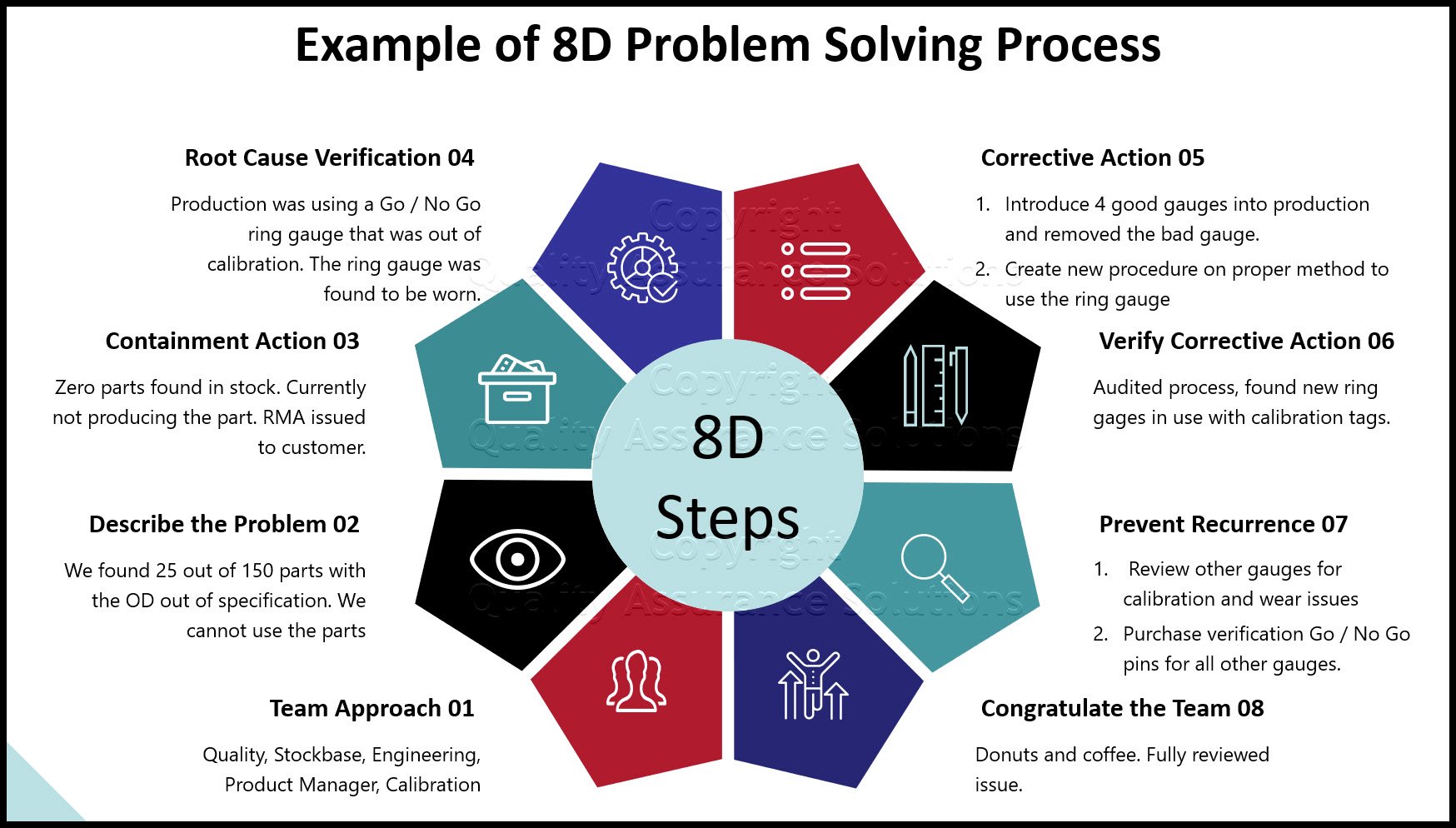

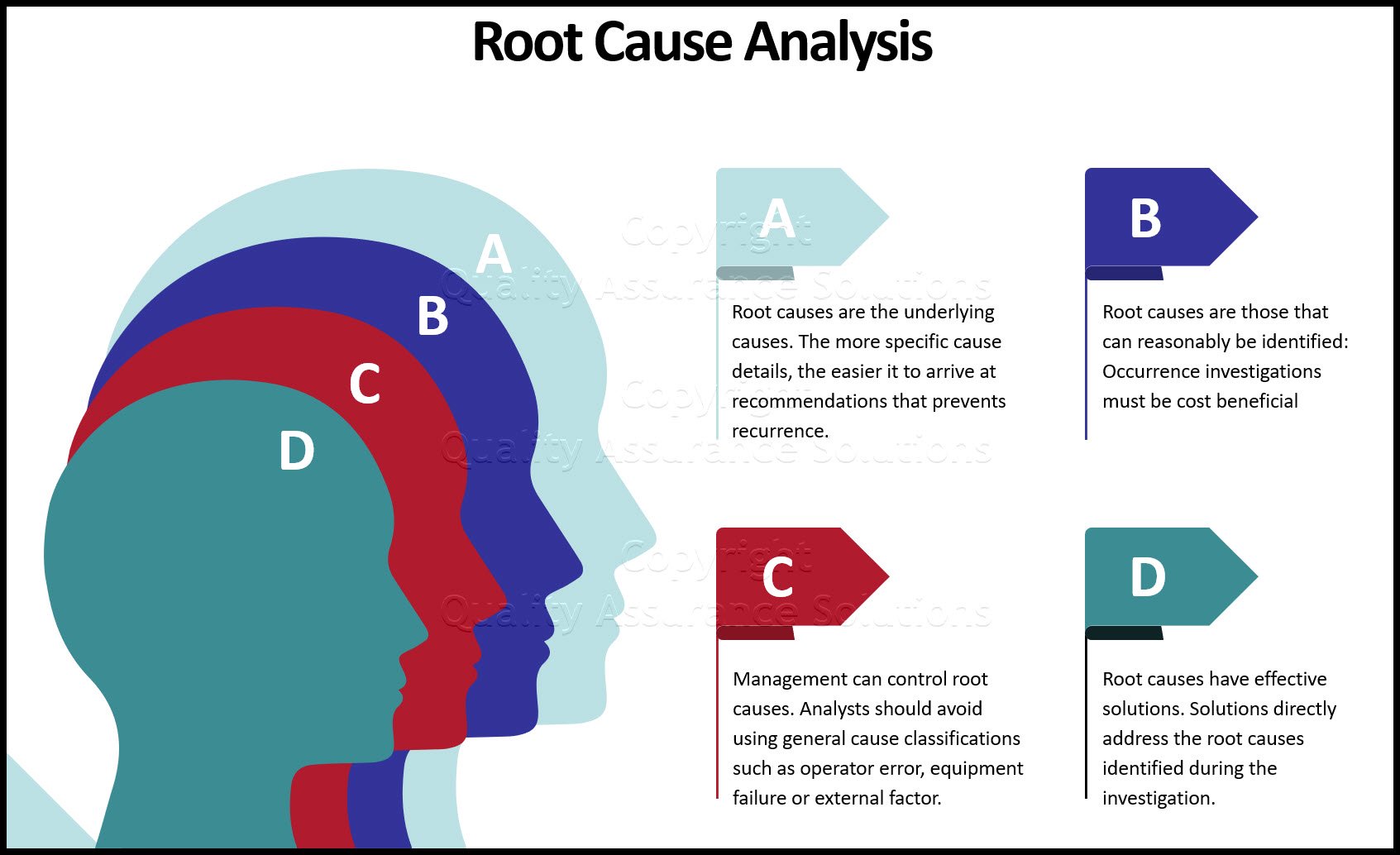

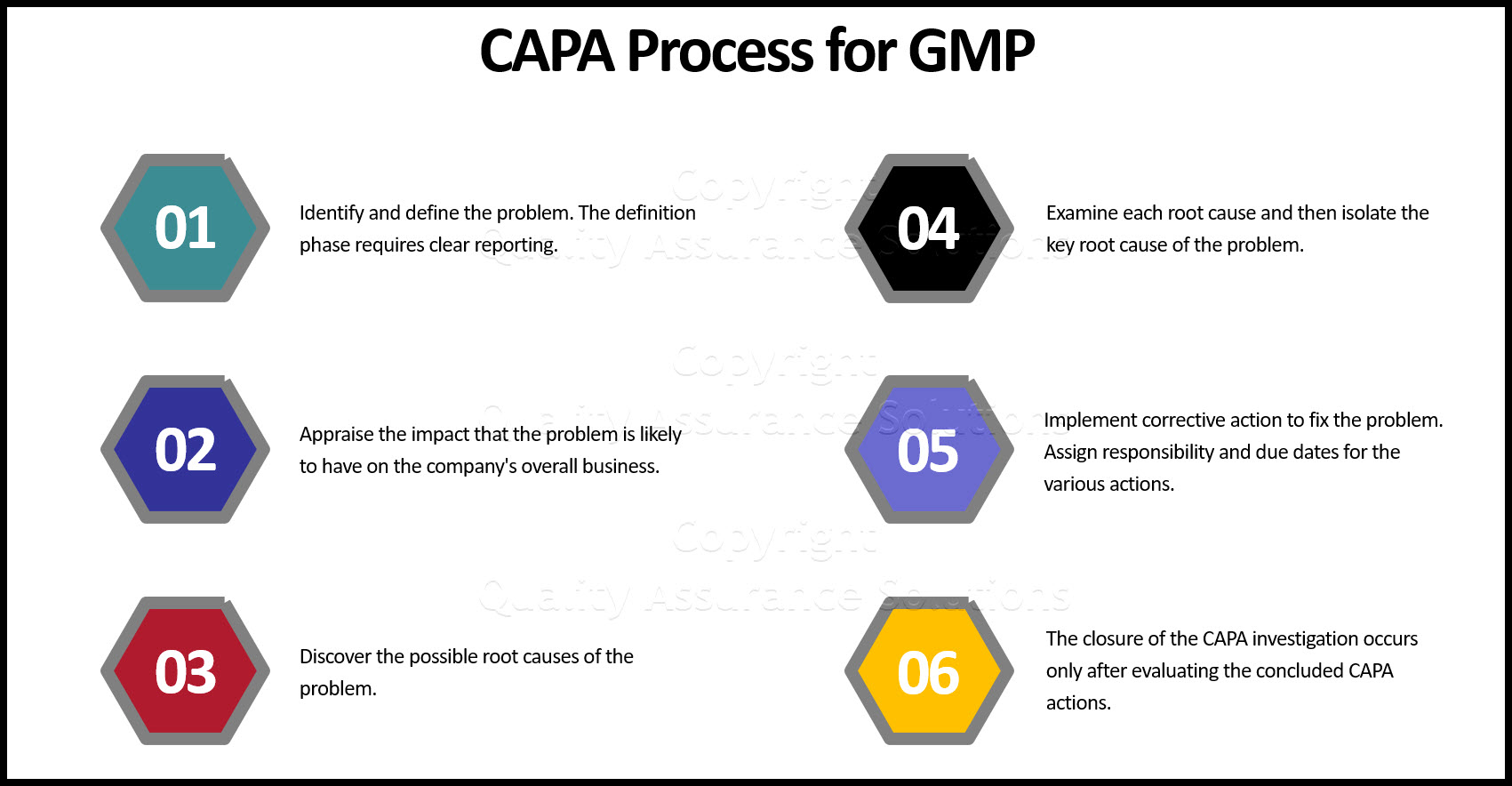

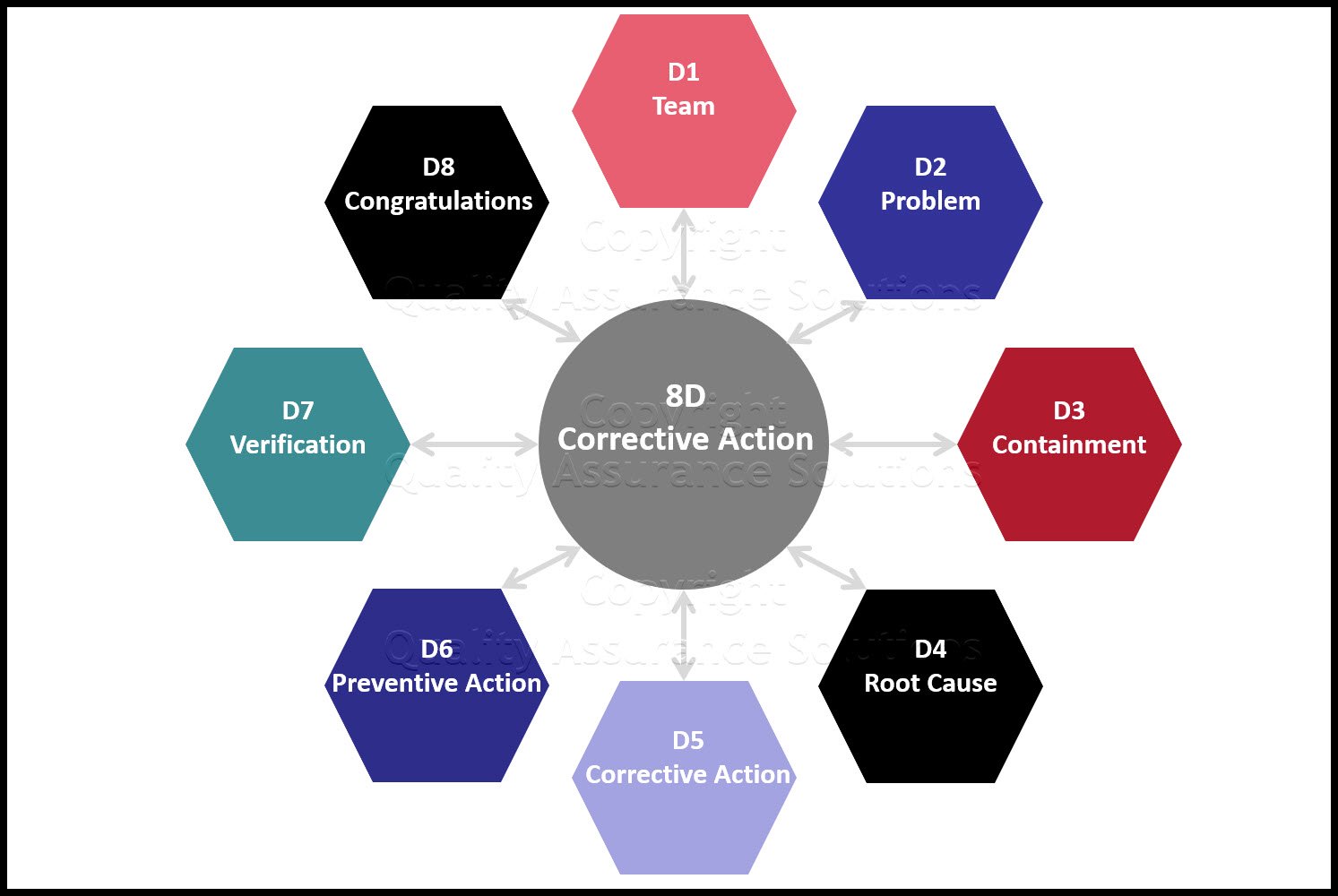

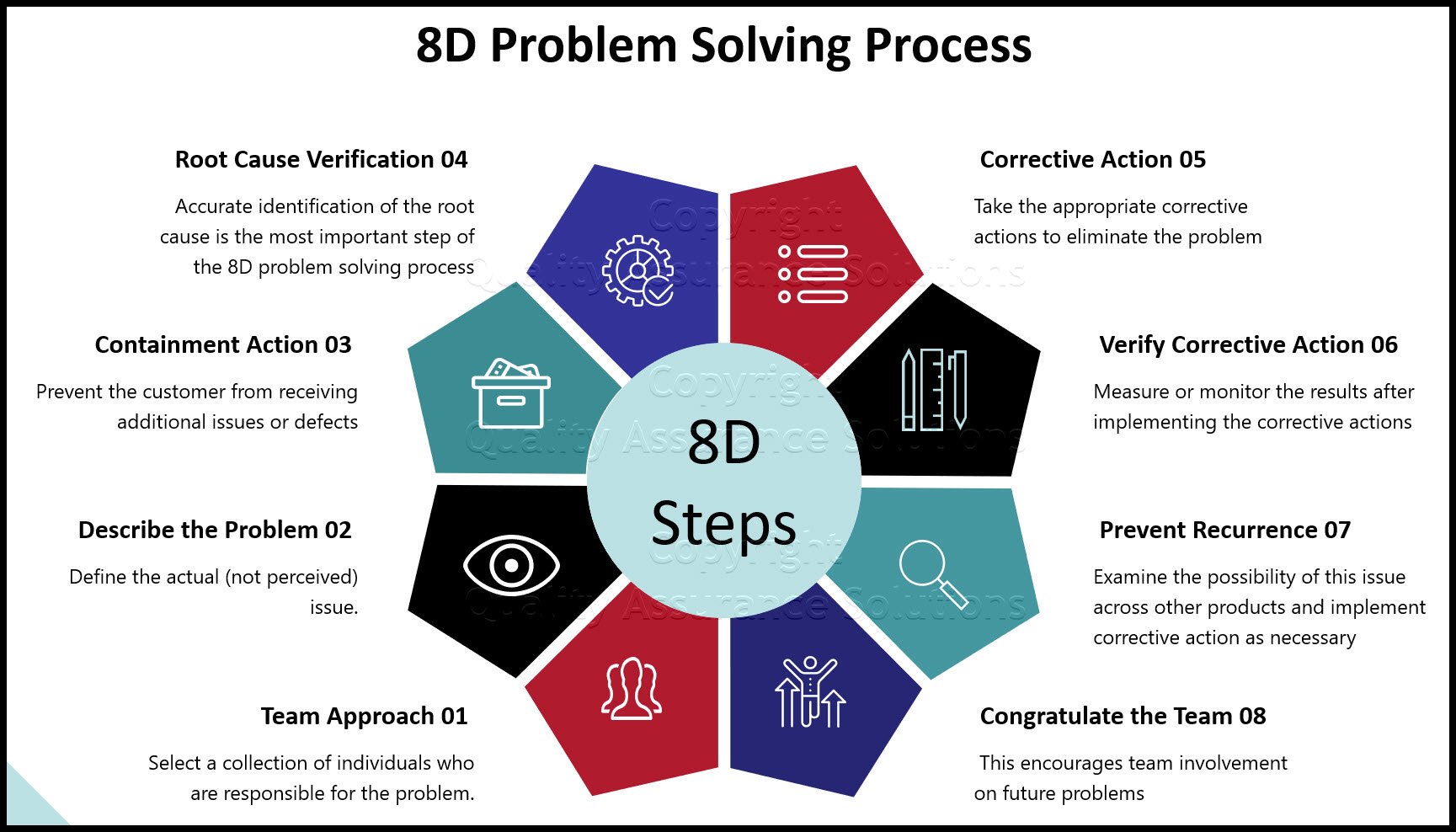

For your Root Cause Corrective Action system we recommend following an eight discipline (8D) approach to resolving internal and external Quality Issues. Your company should have a documented system that describes the method employees follow during the corrective action problem resolution. This document is necessary for ISO 9001 certification.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

8D steps

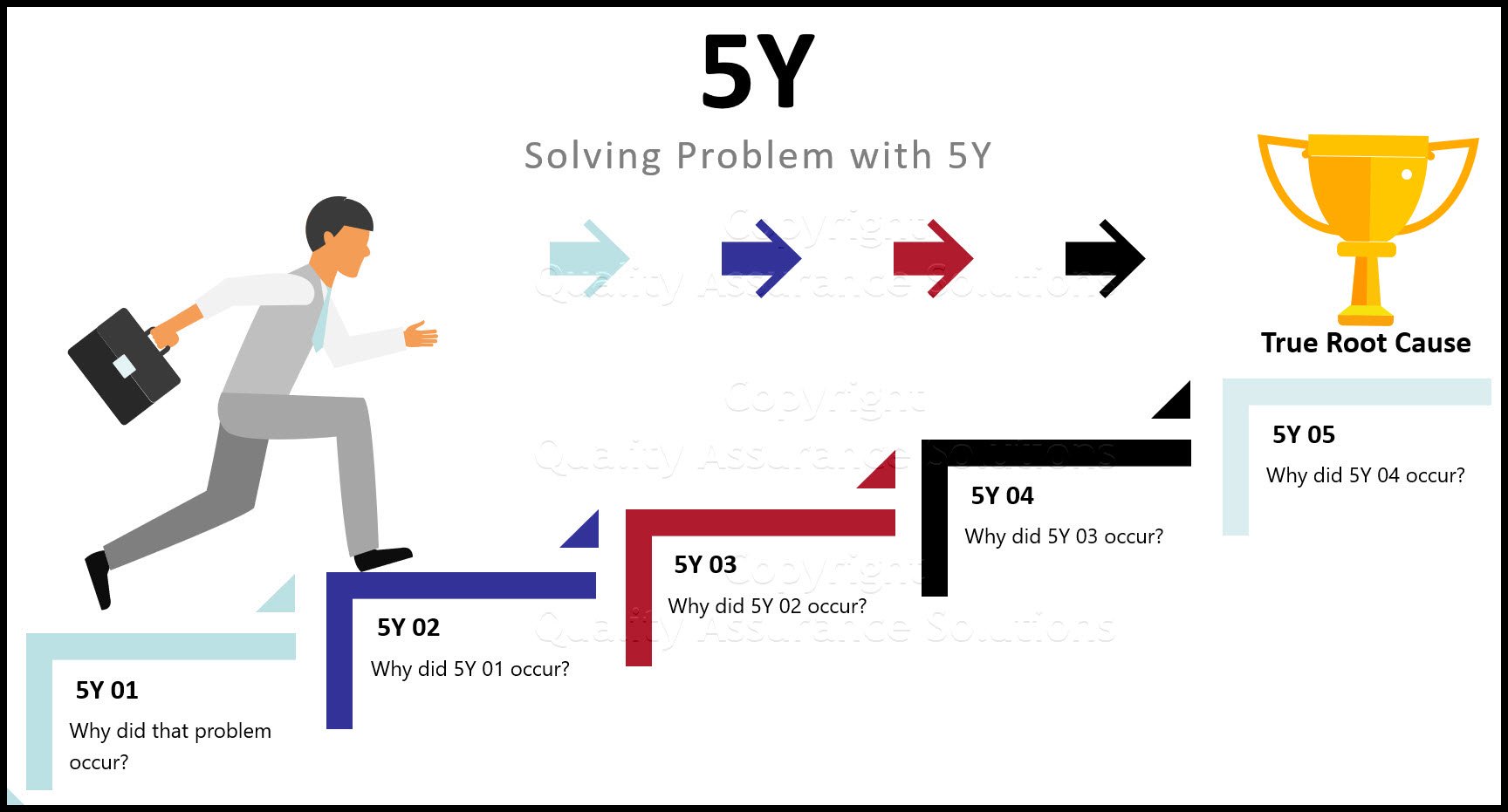

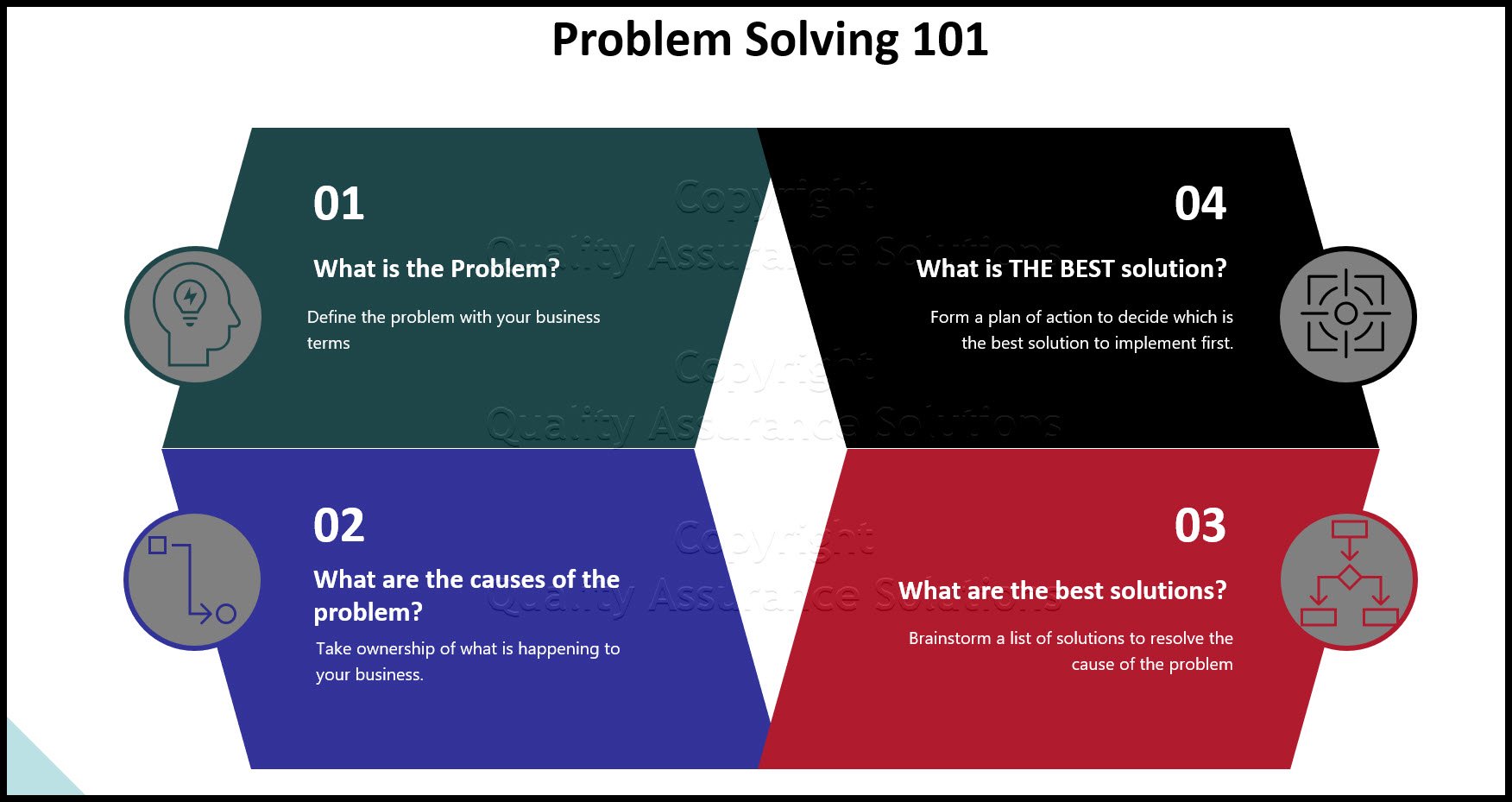

The 8D resolution approach to root cause corrective action includes these steps

- Team approach

- Describe the Problem

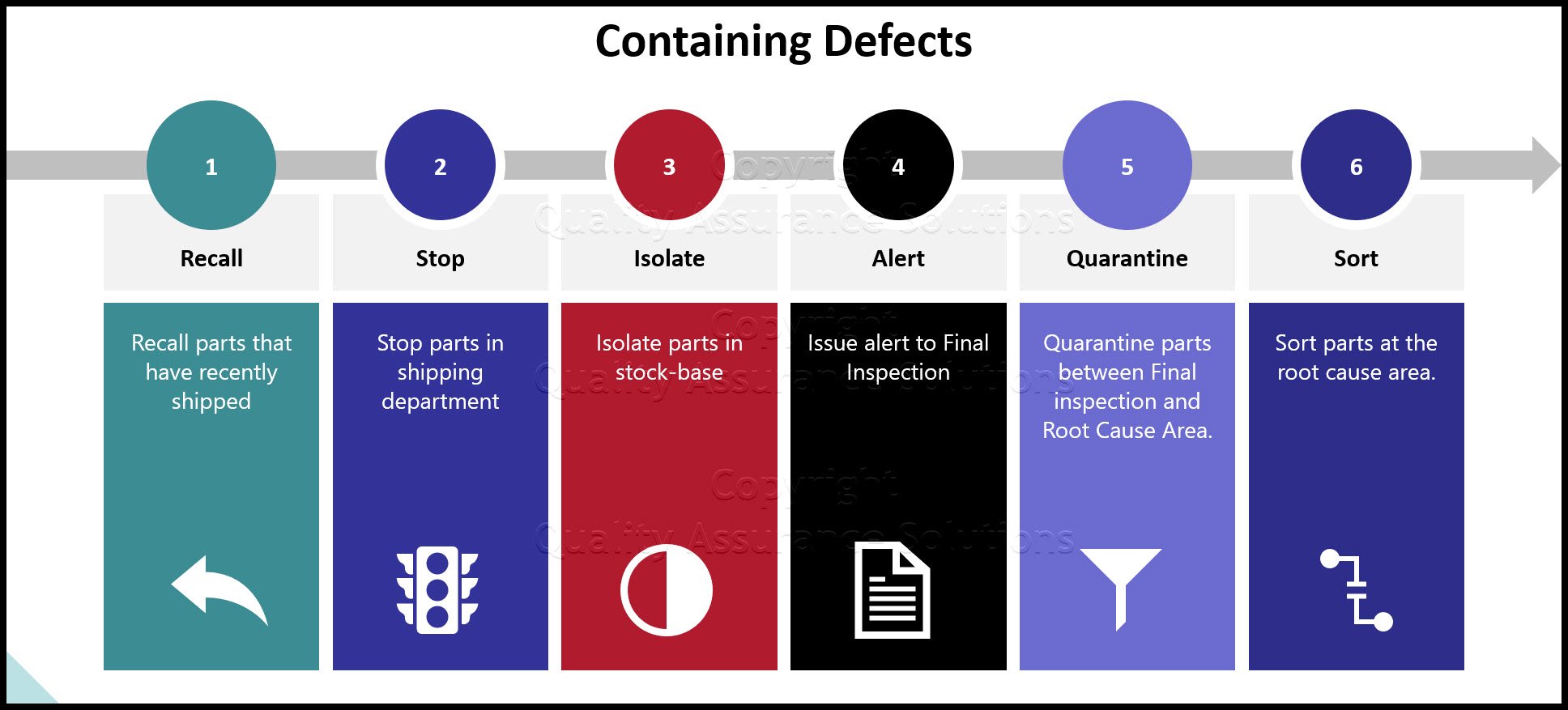

- Containment Action

- Root Cause Verification

- Implement Corrective Action

- Verify Corrective Action

- Prevent Recurrence

- Congratulate the Team

Corrective Action Document

The Root Cause Corrective Action documented system should cover these items:

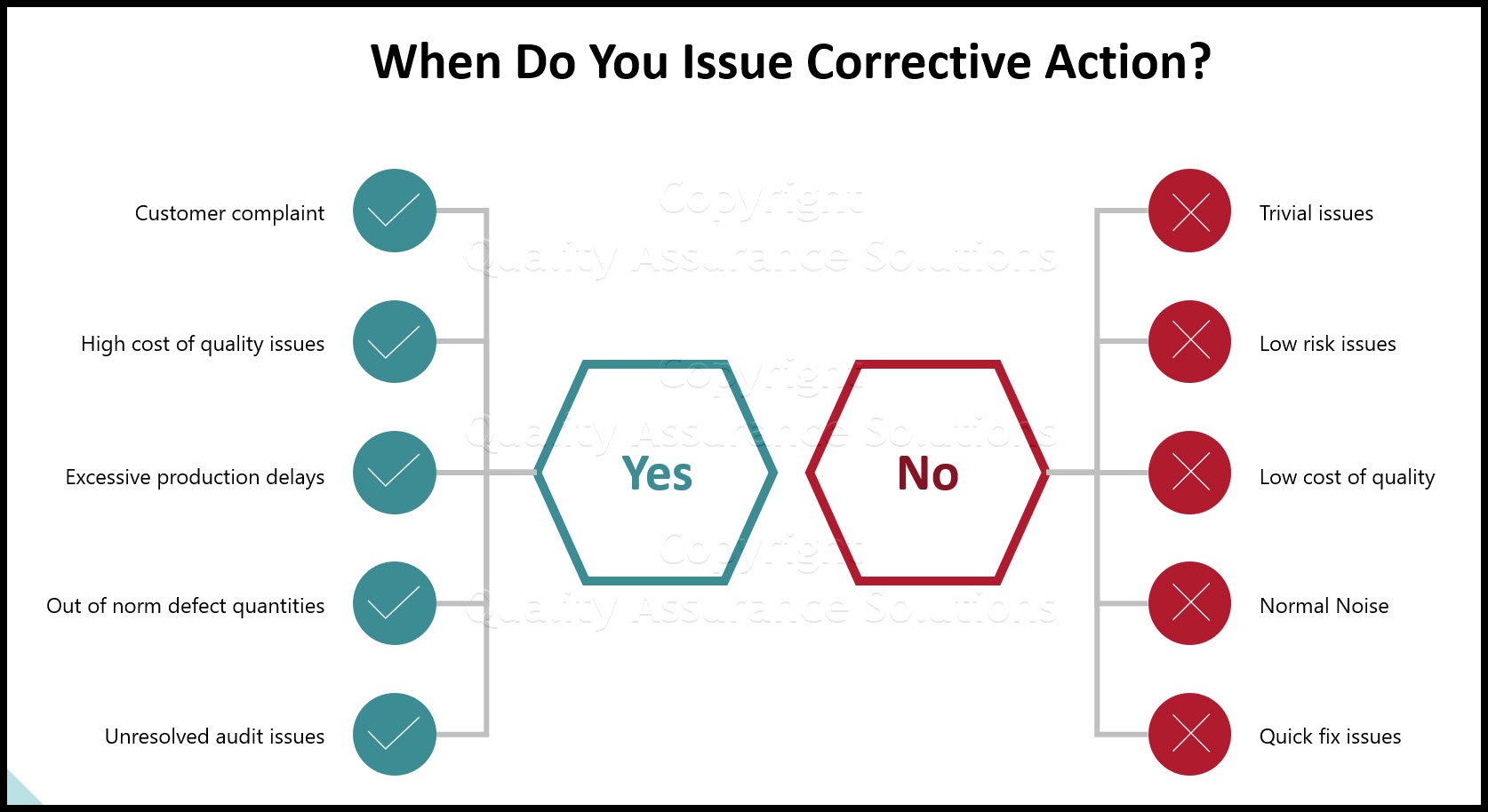

- When corrective actions are issued

- The process of starting the corrective action

- The tracking process for each corrective action from start to closure

- The resolution process of the corrective action

- Who is responsible for managing the corrective action system

- How corrective actions are considered closed

- The method of identifying open corrective action issues

- The timeliness of corrective action

- Provide a sample of the quality record used for corrective action

- The differences in handling internal and external corrective action

- How returned material is managed

- How customer communication is conducted

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Internal vs External

Internal corrective action deals with issues within your business. This can include product quality, process or business systems issues. External corrective action is initiated by your customer. Normally these deal with product quality but they could be business systems issues too.

Corrective Action Reasons

Let’s list some of the possibilities for starting a corrective action

- A customer complaint is received

- An internal product defect

- A product defect that prevents shipping the product

- An out of control process

- Audit findings

- A company system is not performing correctly

- An issue that is causing increase cycle time

- A problem that is costing your company significant money

- A subcontractor issue

- A training effectiveness issue

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Tracking Root Cause Corrective Actions

Your system must track the corrective action from beginning to end. A spreadsheet can do this. Software is better for this purpose.

The corrective action process gathers much reference documentation from beginning to end. All this material should be kept together. Keep it in a manila folder or hyperlinked in your 8D Software.

Preferably software is used and all material can be hyperlinked to the corrective action record. 8D Manager will centralize the reference material for ease of review by the corrective action team. In addition, your tracking system must distinguish between open and closed corrective actions.

Management Responsibility

Within your Corrective Action documented system describe who has the management responsibility. This person needs to have full authority to assure the implementation of the corrective actions.

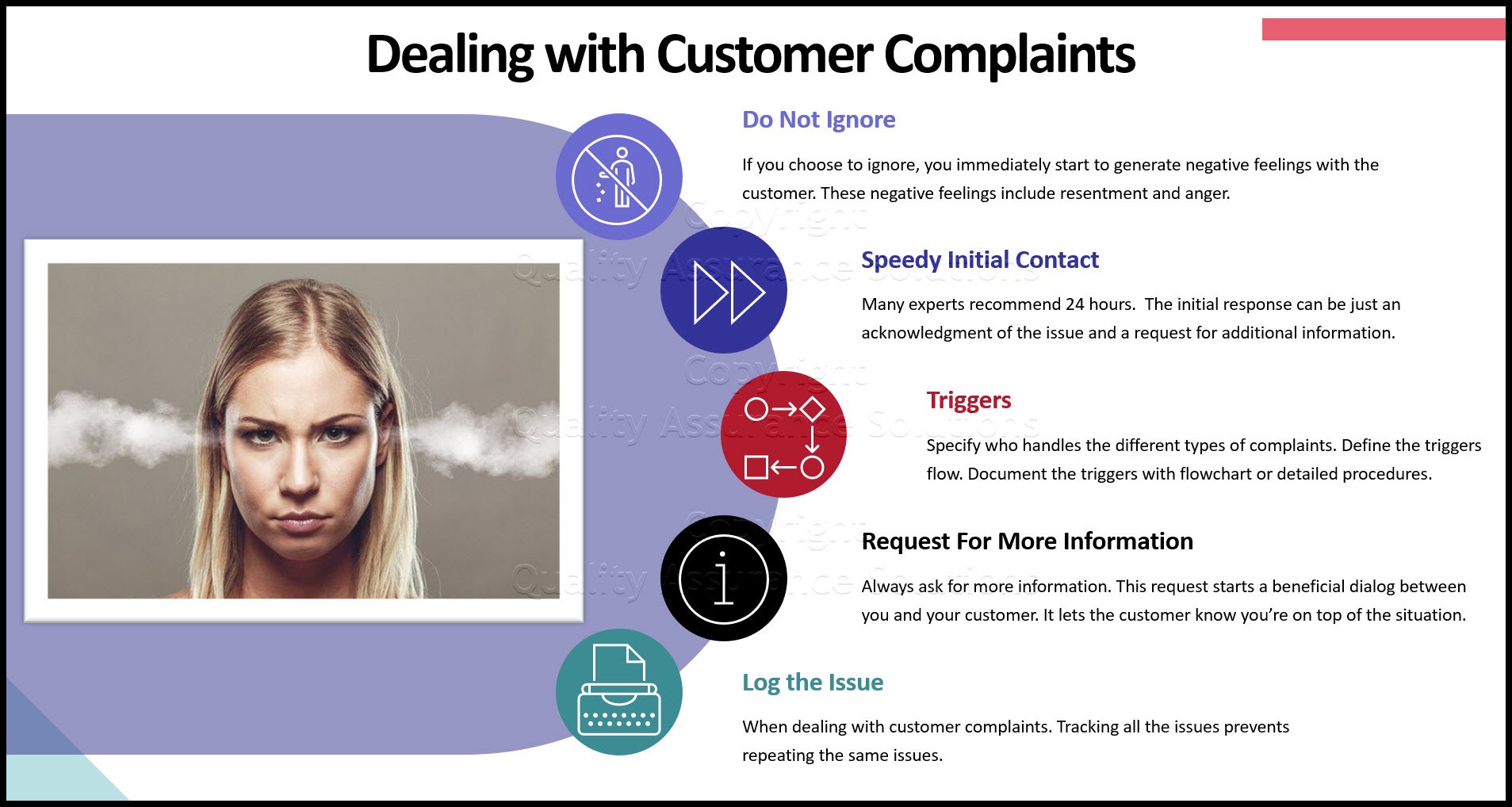

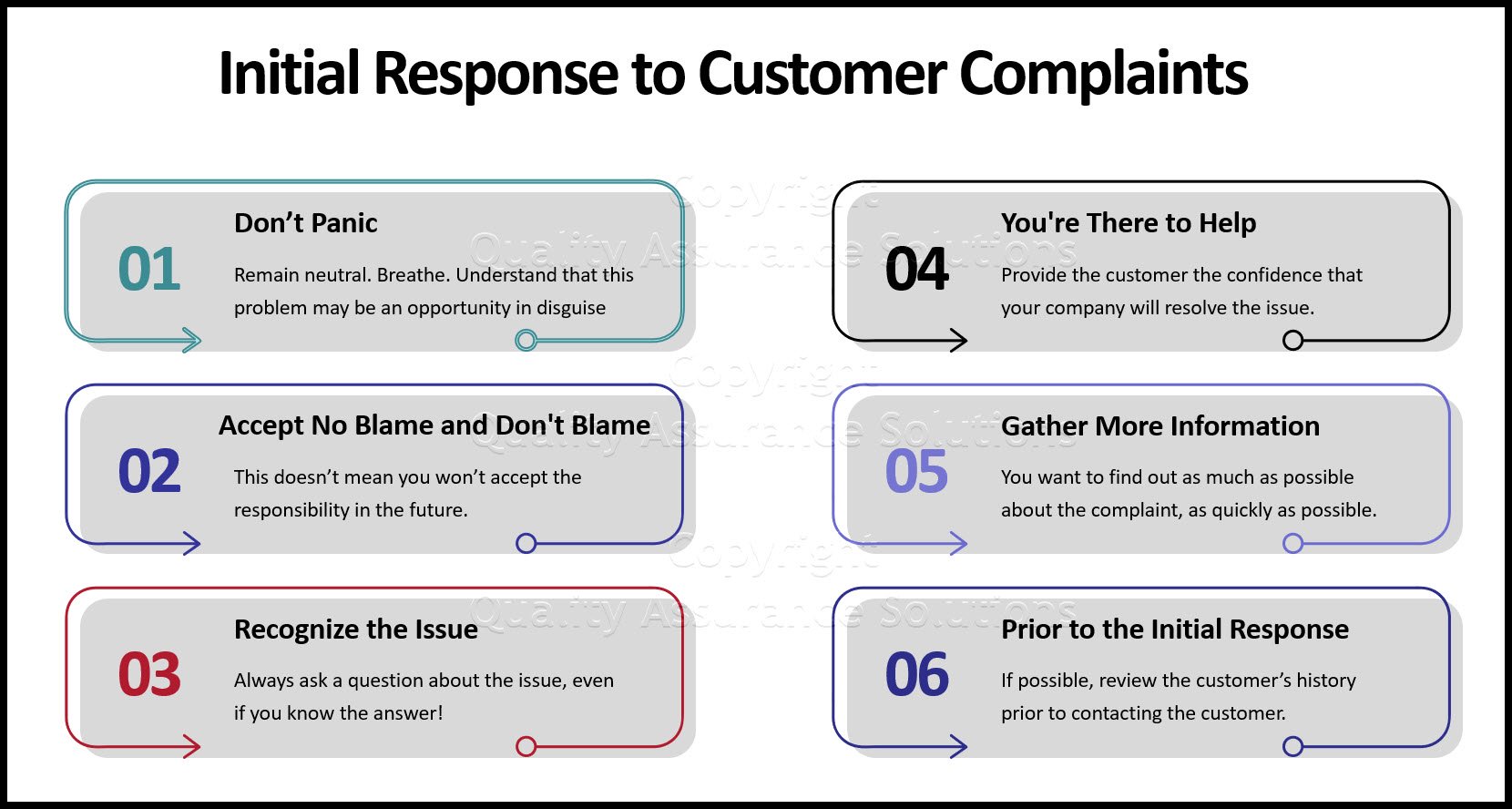

Timely Response

When managing customer complaints, timely response is critical. Do not leave the customer hanging when they initially complain about an issue.

At the beginning of a complaint a customer will be very responsive in giving information to help you resolve the problem. If the customer is ignored then the customer responsiveness will turn to disdain. The customer will immediately start looking for another source. Your current business and future business is at jeopardy.

We recommend an initial written response within 48 hours of the initial complaint. Within that 48 hours complete and document the 8D containment.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Corrective Action Record

The Quality record for the root cause corrective action should cover all of the elements of the 8D process. Responsibilities and dates of the corrective actions will be on the record. The record should have an ID number that separates itself from other corrective action forms.

Your Root Cause Corrective Action System is a Basic System for the following reasons

- You need a documented method for solving problems.

- Customers need assurance that you have a method to resolve their issues.

- It drives continuous improvement.

- It is critical for ISO 9001 certification.

- QAS Home

- Corrective Action

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |