5 Why Problem Solving

One applies the 5 why problem solving tool to determine the root cause of a problem.

As customers become more experience in forcing suppliers to provide corrective action, they will request documentation that covers the 8D approach and 5Y analysis. This article deals with the five why analysis.

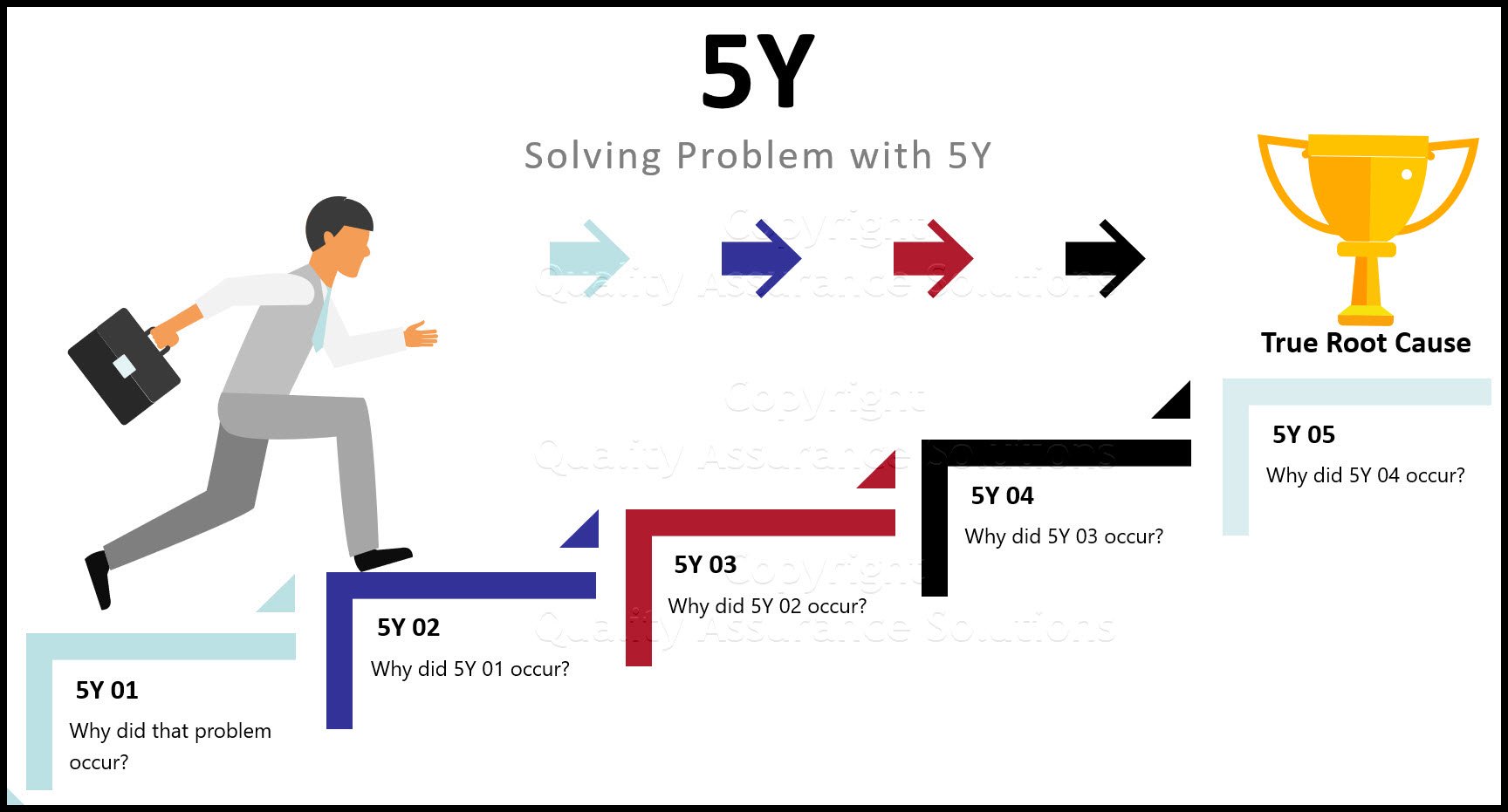

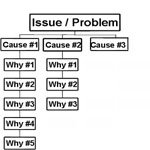

The Five Why Model

In theory, one can easily learn this tool. In practice, this tool is much more difficult to apply.

When a problem initially occurs, we all have an immediate reaction as to the cause of that problem. However, that immediate reaction is a surface reaction only. When it comes to examining processes or systems, there are other deeper root causes for that problem. 5Y helps us find the fundamental root causes of a given problem. 5 why problem solving methodology helps us uncover the details behind the problem.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

How does the 5Y tool work? Here is a quick flow...

- Problem occurs

- Why did that problem occur = sub root cause #1

- Why did sub root cause #1 occur? = sub root cause #2

- Why did sub root cause #2 occur? = sub root cause #3

- Why did sub root cause #3 occur? = sub root cause #4

- Why did sub root cause #4 occur? = key root cause #5

5Y means we asked the question "why" 5 times from the problem statement until you reach the primary root cause. The primary root cause or key root cause directly determines the other sub root causes. When solving the problem, you focus your efforts on the key root cause.

For each why question, you focus on the last sub root cause. When applying this tool, asking "why" 5 times may not be necessary. You may only need to ask "why" 3 times to come to the correct root cause. The number 5 is an arbitrary number. The 5Y method is a process of asking why a sub root cause occurred until you reveal the key root cause.

When doing the 5Y analysis, use a team approach to determine the root causes. Document each determined sub root cause. When you identify the key root cause, be sure to positively identify that root cause on your document with a check mark or underline.

Additional 5Y Actions

As mention above asking "why" five times may not be sufficient, you may need to ask more than 5 times.

Once you determined the key root cause from the 5 why problem solving methodology process you are not finished with the 5 why analysis. You need to verify that root cause. You verify the key root cause by witnessing the root cause in action. Then check to see that you duplicated the problem.

After verification of the root cause, you must determine your corrective actions for that key root cause. Document the corrective actions on the 5Y form. Implement these corrective actions. If you are completing a corrective action for a customer, proceed with the 8D analysis.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

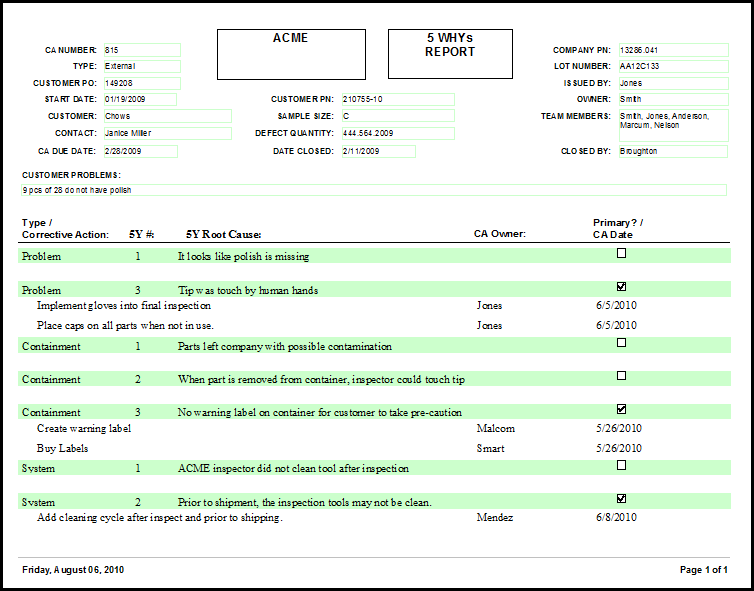

5 Why Problem Solving and Formal Corrective Action

Customers may require one of two different systematic methods when using when using the 5 why problem solving tool. These are;

1) Prevent - Predict - Protect

2) Problem - Containment - System

When a customer request one of these 5y analysis from you, you apply the 5 why problem solving template tool to each of the 3 elements. So for Prevent - Predict - Protect method you apply a 5Y approach separately to Prevent, Predict and Protect processes at your company.

Prevent - these are the processes at your company that did not prevent the problem from occurring. Why did your process not prevent the failure from occurring?

Predict - These are the process at your company that did not predict this issue from occurring. Why did your current processes not predict this failure mode? Why did your planning or development process not see this as a potential issue?

Protect - These are the processes at your company that protects the customer from receiving defective product. Why did your quality processes not protect the customer from the failure mode?

Problem - This is the root cause to the problem. Why did the problem occur.

Containment - This is the root cause reason why defects escaped your facility. Why did you process not catch these defects prior to shipment?

System - These are the root systems that did not foresee this potential root cause. This could also be lack of systems to prevent the root cause. Why did your systems not predict or catch this failure mode.

When conducting 5 why analysis, use a template that lets you capture the data. The template needs to isolate each of the 3 elements. This allows the customer to quickly review your analysis. If you use 8D Manager, you can quickly create a 5Y form for each 8D corrective action. 8D Manager software separates each of the elements.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

More on Five Whys

Description:

The Five Whys also named 5-whys analysis method is used to isolate the true root cause of a problem.

When dissecting a problem, ask why the issue occurred. For each reason given, ask why that reason happen. After asking why repeatedly for every reason, you will identify the true root cause.

5 why means 5 cycles, but you may not need 5 cycles. Sometimes 3 or 4 cycles isolates the cause. By the time you get to the 4th or 5th why, most likely you're looking squarely at management practices.

This methodology is closely related to the Cause & Effect (Fishbone) diagram, and can be used to complement the analysis to complete a Cause & Effect diagram.

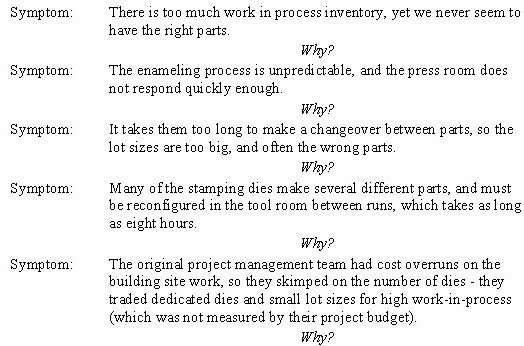

Example:

Here is a real world example from a kitchen manufacturer:

Root Cause: Company management did not understand lean manufacturing, and did not set appropriate project targets when the plant was launched.

- QAS Home

- 8D Reports

- 5 Why Problem Solving

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |