What Is Quality Control?

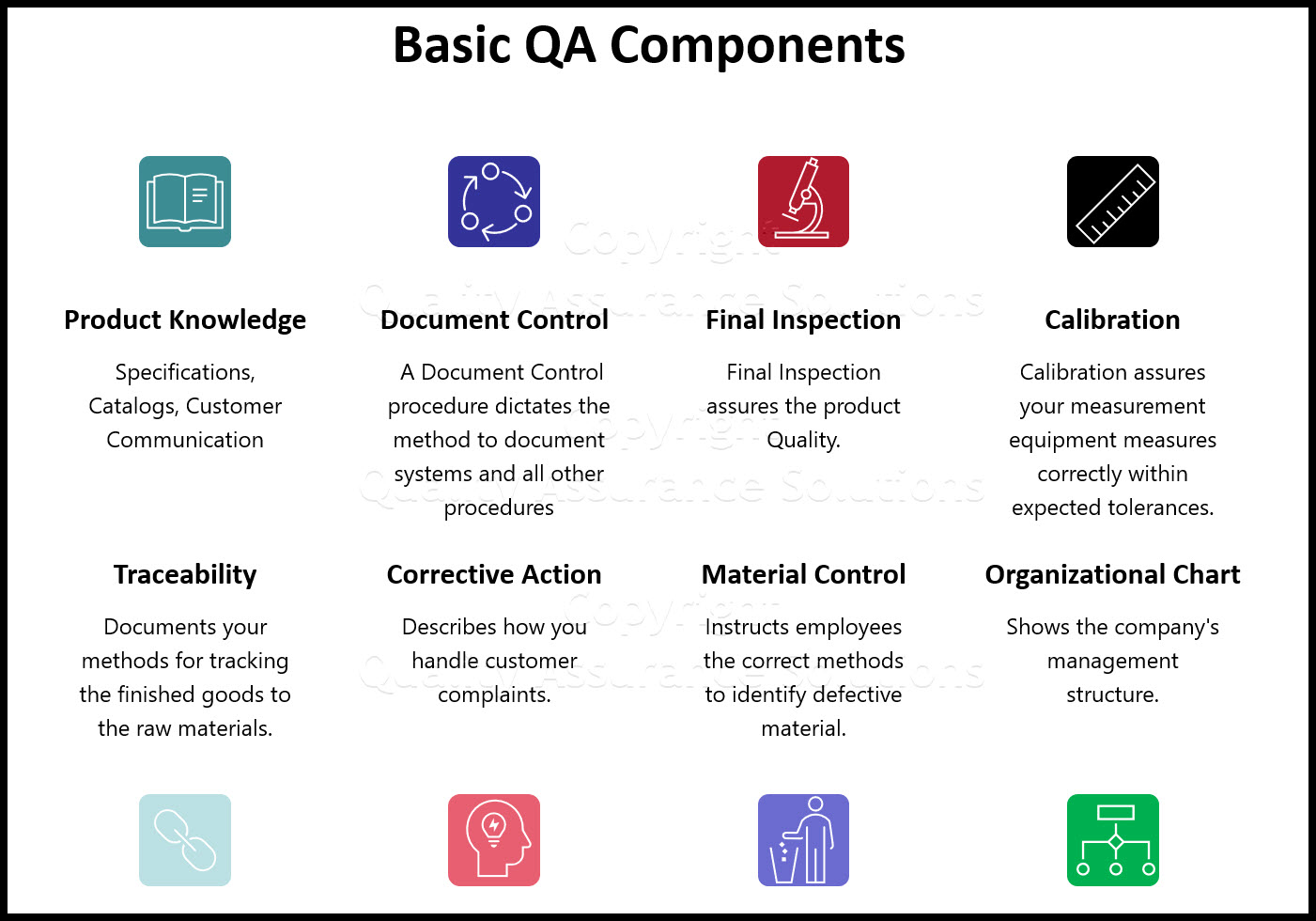

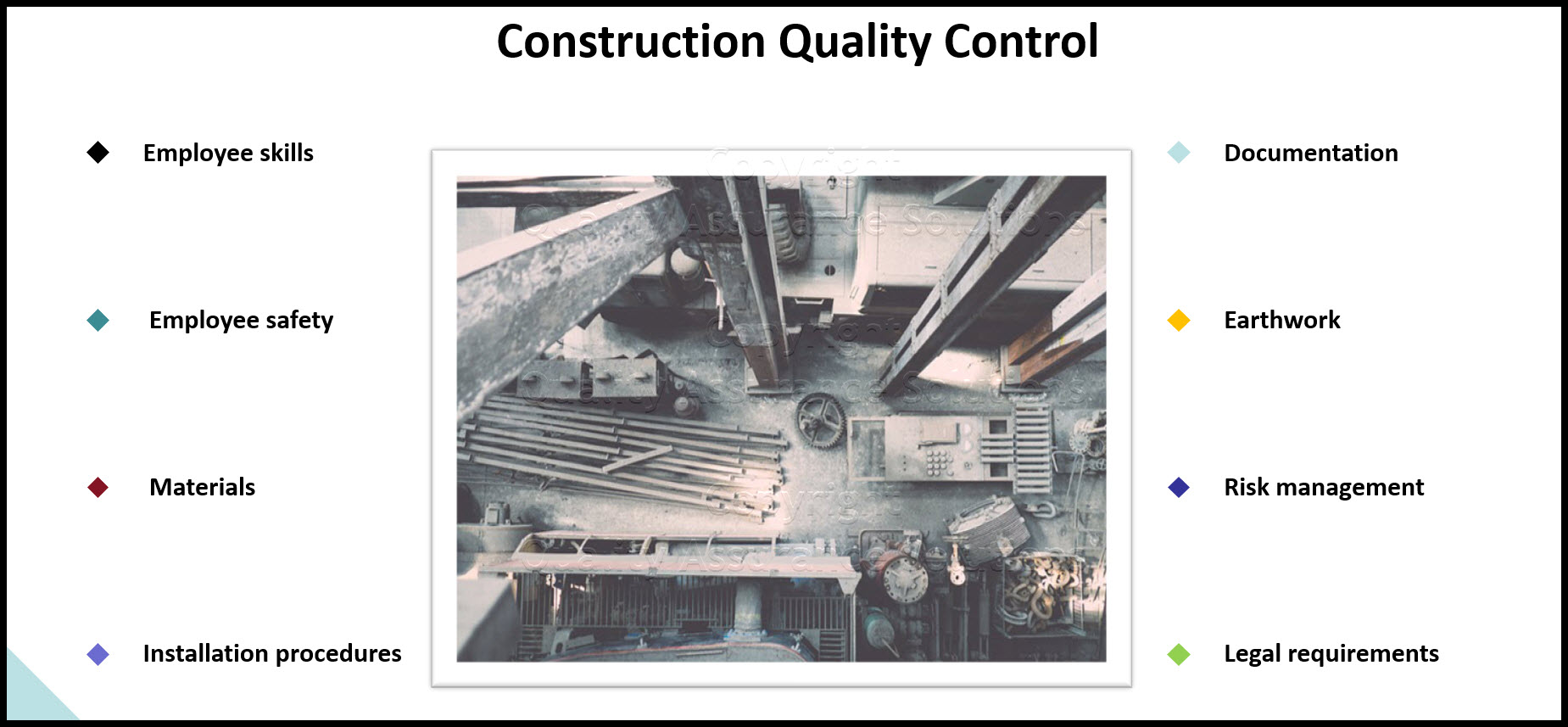

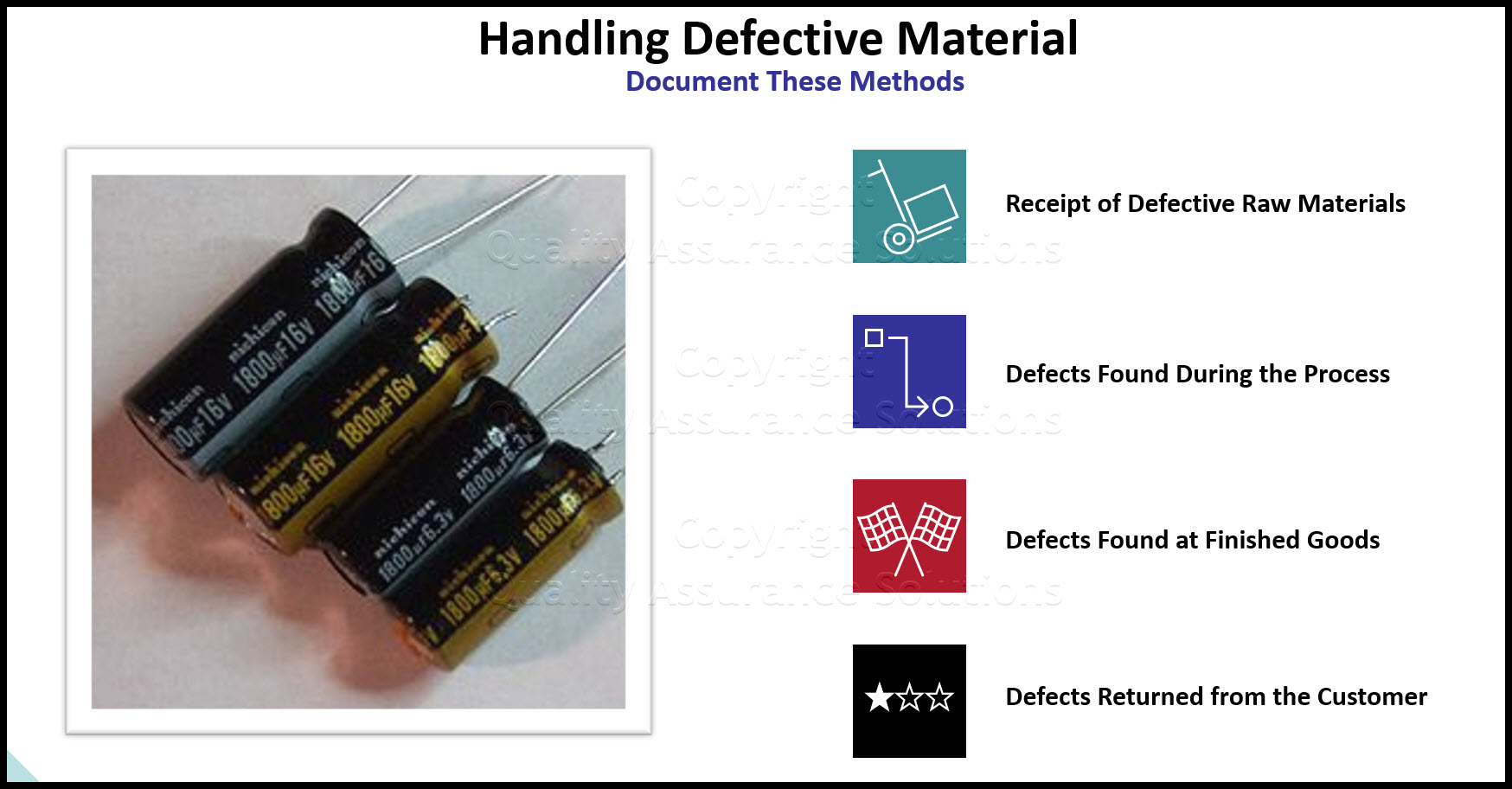

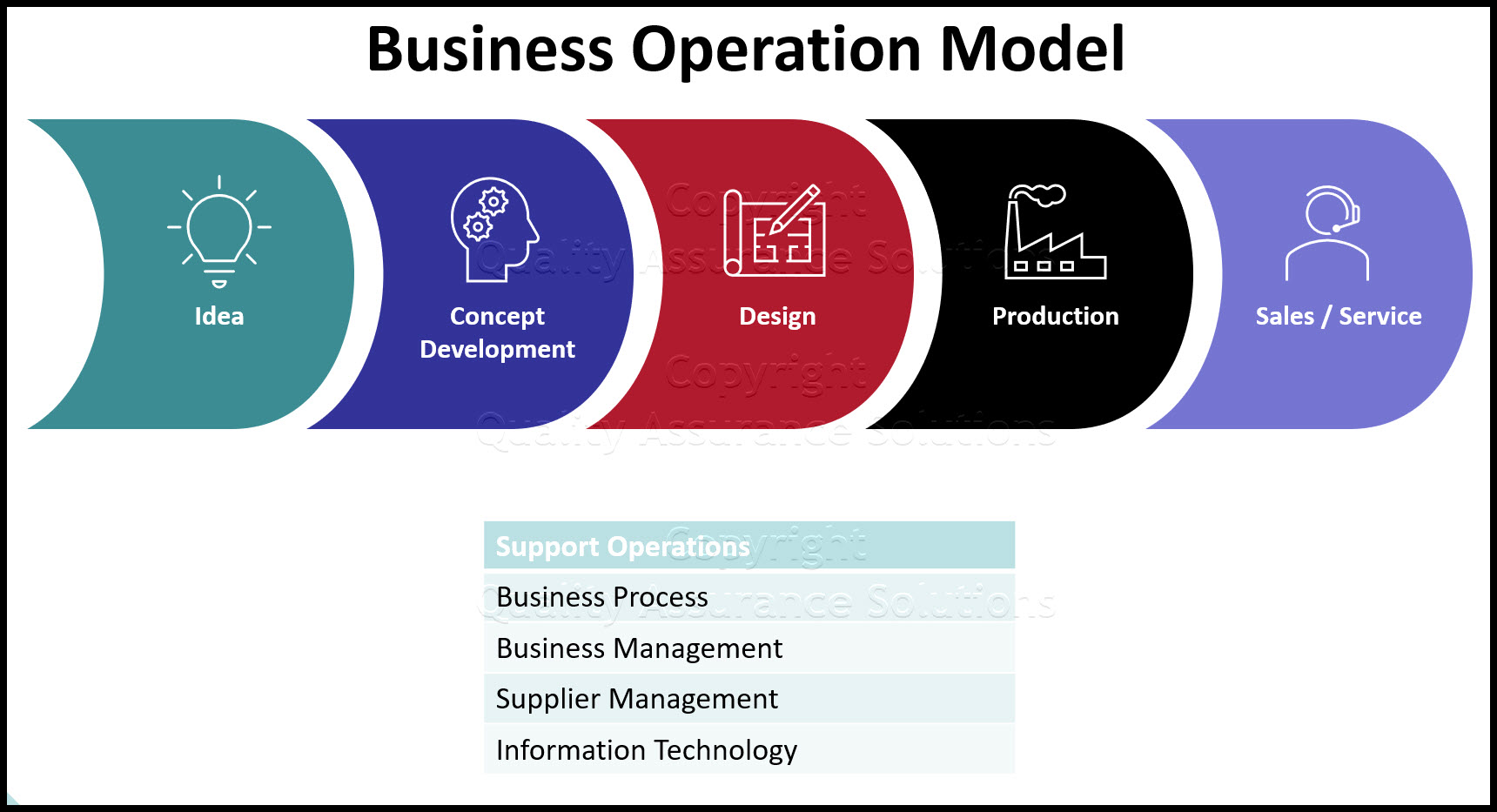

What is quality control? Quality control are the systems in your company that detects defects. Quality control prevents customers (internal and external) from receiving defective products. This includes inspection points for receiving inspection, inprocess inspection and final inspection. When establishing these systems you need to consider these items

- The procedure for inspection

- The sampling plan for inspection

- The quality record for inspection

- The accept / reject criteria or specification.

- The plan for handling and identifying the defective material

- The review and corrective action of the defective material (MRB)

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Receiving Inspection

Receiving inspection are the controls you use to prevent defective materials from entering your production lines. Your company decides which materials are critical to your process. Critical materials directly affect product quality. These materials must be controlled.

Consider these questions when creating your receiving inspection procedure.

- How are the materials inspected?

- What is the inspection procedure?

- What is the sampling plan?

- Where is the inspection documented?

- How is the accepted material distinguished differently from the rejected material or unqualified material?

- What happens to rejected material?

- What is the process of notifying the supplier of rejected material?

- How do you prevent good and rejected material from being mixed?

- What is the staging process for unqualified material?

Inprocess Inspection

Inprocess inspection

You might have inprocess inspection in various departments in your company as production is flowing through those departments. This could include

- Inspecting machine settings,

- Inspecting machine output

- Inspecting the incoming material

- Inspecting the outgoing material

- Statistical Process Control

When establishing an inprocess inspection stage consider these items

- Do you need the inspection to ensure the quality of the part?

- Do you have a operating procedure for the inspection tool?

- Do you have specifications for the inspection?

- Have you consider SPC for the inspection?

- Have you determined the sampling plan?

- Is there a quality record for the inspection?

- Is someone reviewing the quality record?

- Is there a Material Review Board process if issues are found?

- Who is notified when issues are found?

- Is production stopped when defects are found?

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Final Inspection

Final inspection should occur on the product prior to shipping to the customer or prior to storing in inventory. When implementing final inspection activities, review the above inprocess inspection information.

Final inspection is more dependent on customer requirements. The customer may have a specification or a drawing. Perhaps you are selling to a catalog or web page. Final inspection assures the customer is receiving the items they order.

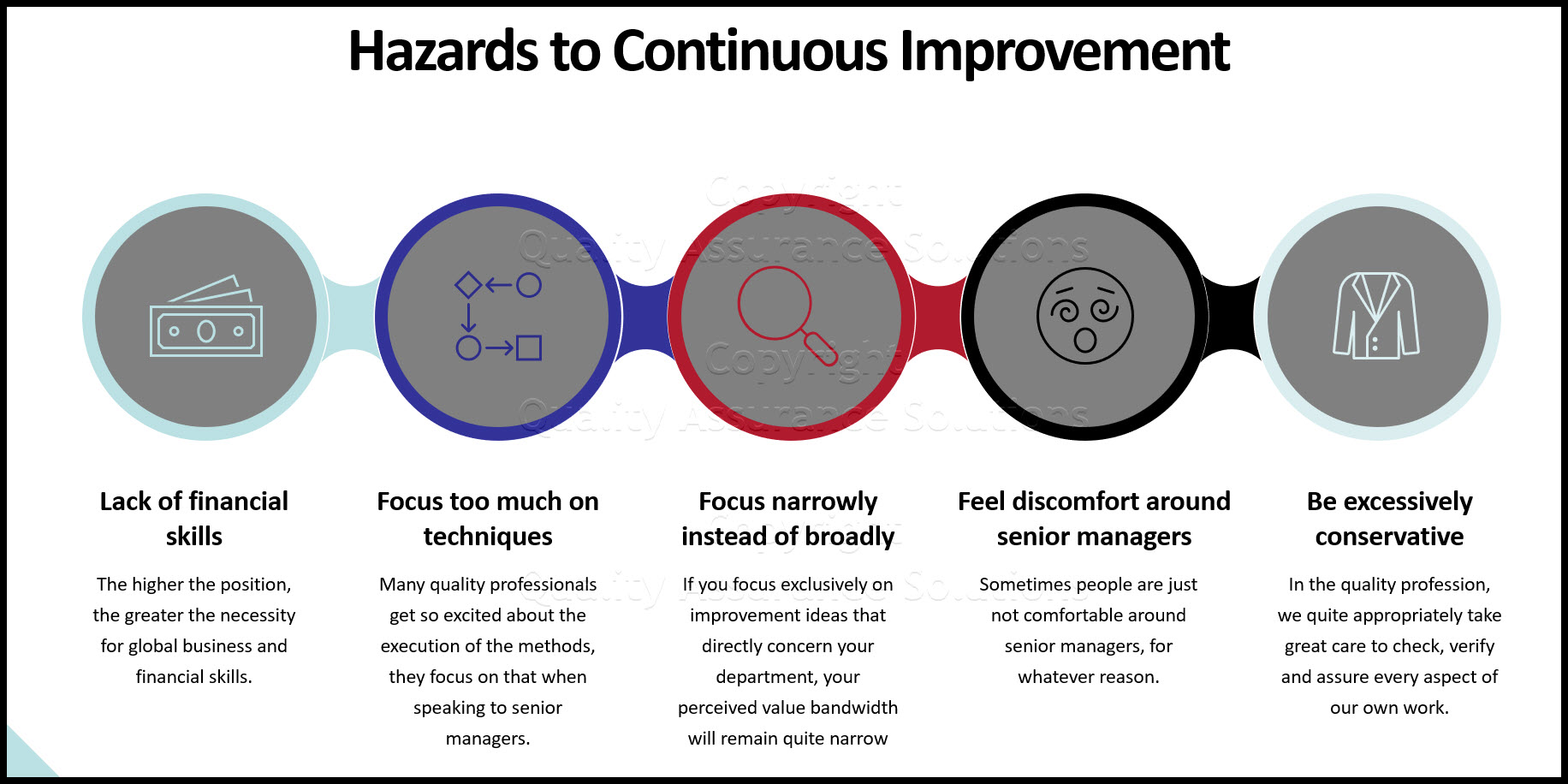

Final inspection occurs on the product. If defects are found, then the product may need to be reworked or scrapped. Finding defects at this time can cost your company serious money because the process that caused the defect may still be making the same defect on fresh product. In addition all value added steps have been placed in the product. All money spent on creating that product will be wasted if the product is scrapped.

As a preventive measure, final inspection should review the inprocess inspection documentation to assure that the data is in order.

Documentation for final inspection should be formal as the customer may ask for the data. Design The quality record so it meets your customer requirements and formats. If the customer is asking for the data, be sure to get their acceptance to the format prior to sending the initial data to the customer.

What is Quality Control inspection types?

Mechanical - These are dimensional measurements of the item

Performance - This is an inspection for the function(s) of the product.

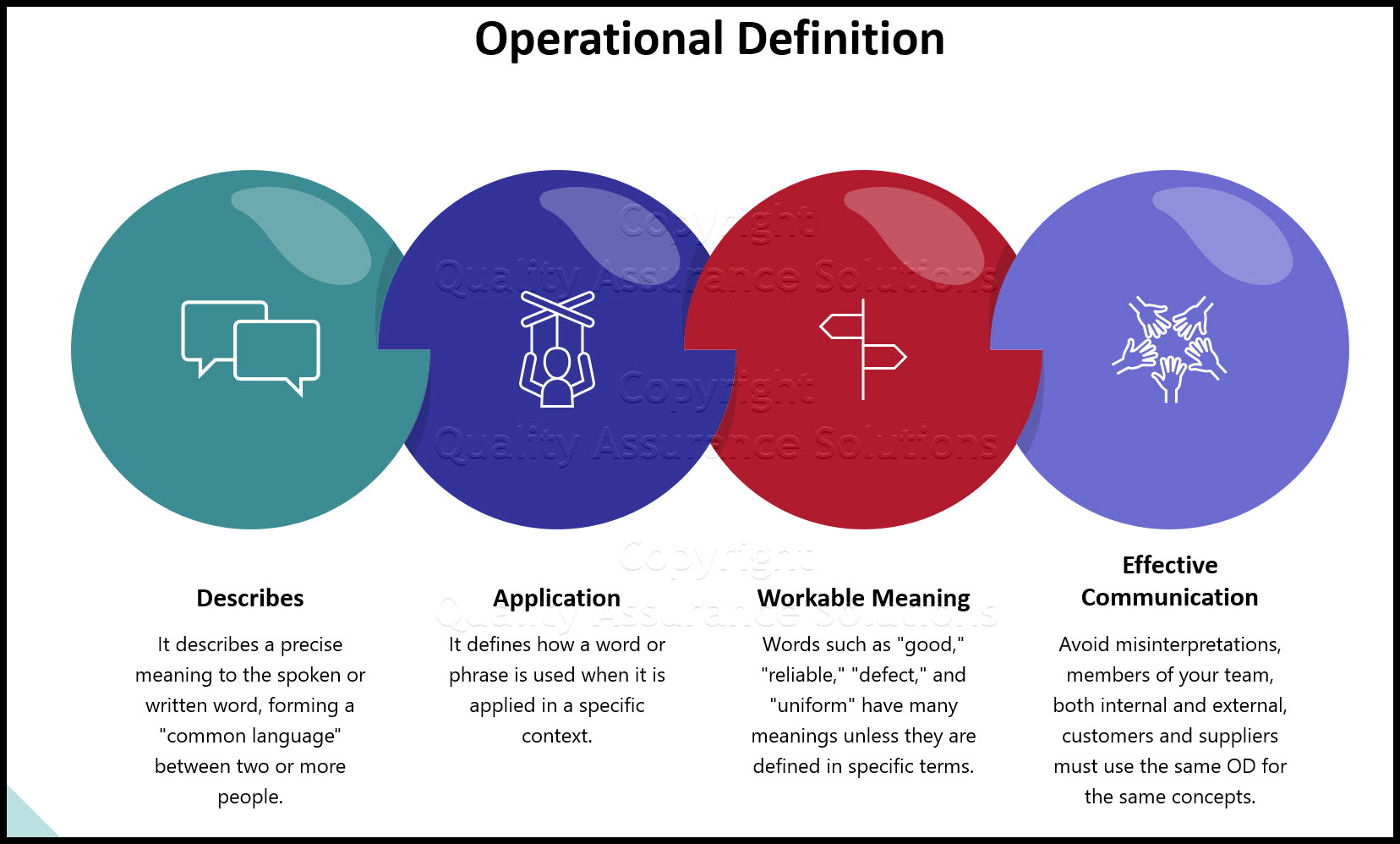

Visual - Looking for certain undesirable characteristics. These characteristics need to be defined

What is quality control definition? The operational techniques and individual activities that focus on controlling or regulating processes and materials to fulfill requirements for quality. The focus is on preventing defective products or services from being passed on.

- QAS Home

- The Basics

- What Is Quality Control

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |