Dr Deming Point 5

Constant Improvement

There is not doubt that there is no right improvement tool for all operations and/or situations. The company that hangs its reputations on one is doomed to eventual extinction.

-Ernst & Young

Dr. Deming was good friends with Dr. Shewhart. Dr. Shewhart is the father of statistical process control. Dr. Shewhart taught him SPC and other statistical quality control methods. These theories became the foundation for Dr. Deming’s management model.

Progressive companies use SPC for monitoring, controlling, isolating and eliminating unexpected problems, and tracking improvement. SPC is a visual statistical aid that tells operators when to make adjustments to the process and when to leave the process alone. Modern SPC software can be programmed to provide specific instructions for the operator to follow.

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

Improve Constantly and Forever the System of Production and Service - Deming Point 5

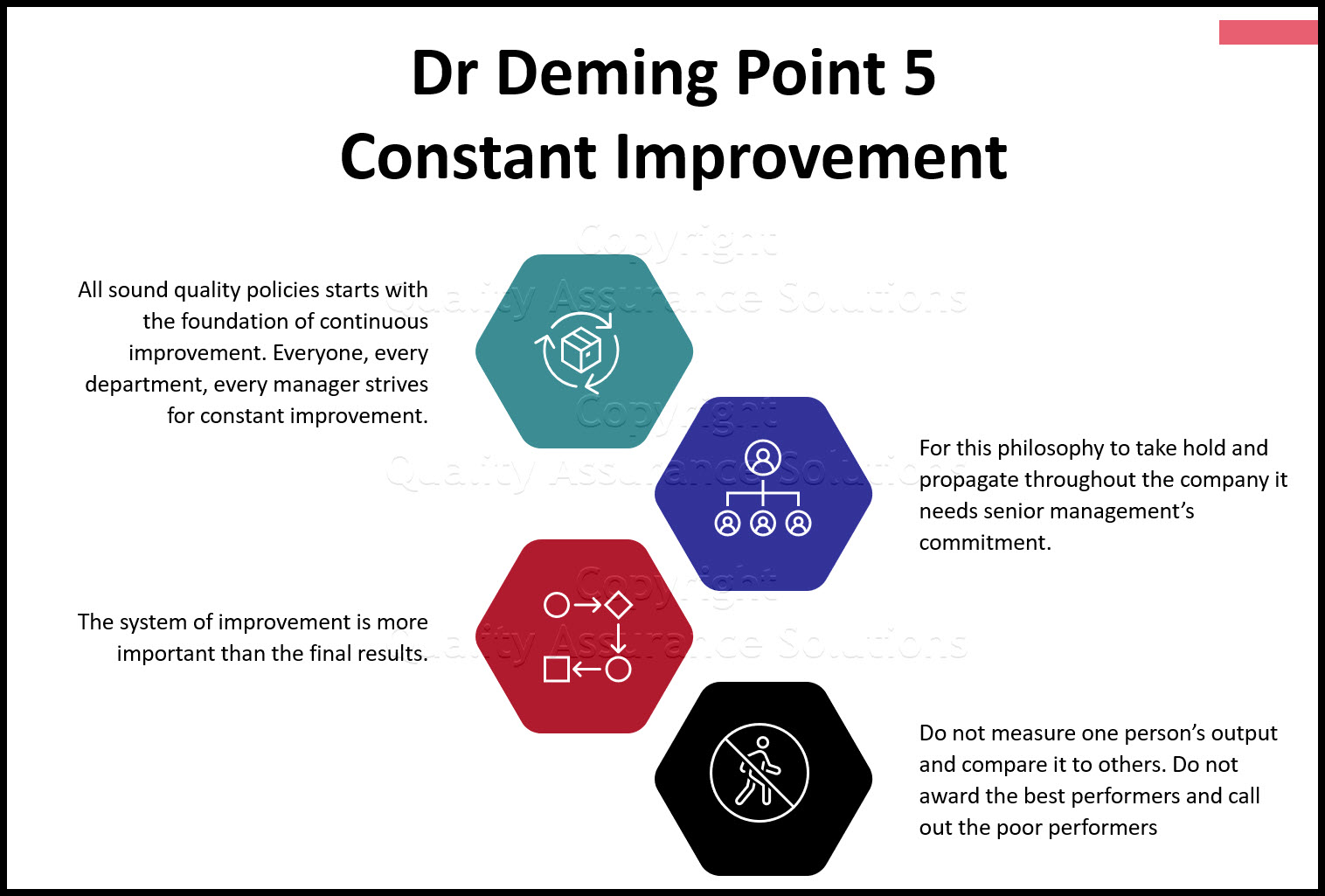

The main goal of any commercial business is to make money. The second all encompassing goal is to “continually improve”. All sound quality policies starts with the foundation of continuous improvement. Everyone, every department, every manager strives for constant improvement.

Continuous improvement starts at the top. For the quality department, it starts with your quality management review. For this philosophy to take hold and propagate throughout the company it needs senior management’s commitment. The quality management review includes senior management improvement ideas and actions.

Dr. Deming Point 5 did not believe in measuring every facet of a company’s business. He believed that you constantly have to use the quality improvement tools to drive improvement. The system of improvement is more important then the final results.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Dr. Deming did not want management to measure one person’s output and compare it to others. Do not award the best performers and call out the poor performers. Individual performance is based on many things such as assigned responsibilities, workload, knowledge, relationships and environment. The employee cannot control many of these items and management must understand this. Continuous improvement is focused on perfecting the system so all employees improve.

Dr Deming’s 14 points

1. Create constancy of purpose for improvement of product and service.

2. Adopt the new philosophy

3. Cease dependence on mass inspection

4. End the practice of awarding business on price tag alone

5. Improve constantly and forever the system of production and service.

6. Institute training

7. Institute leadership

8. Drive out fear

9. Break down barriers between staff areas

10. Eliminate slogans, exhortations, and targets for the workforce.

11. Eliminate numerical quotas.

12. Remove barriers to pride of workmanship.

13. Institute a vigorous program of education and retraining.

14. Take action to accomplish the transformation.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |