TQM History

This page describes TQM History. TQM stands for Total Quality Management.

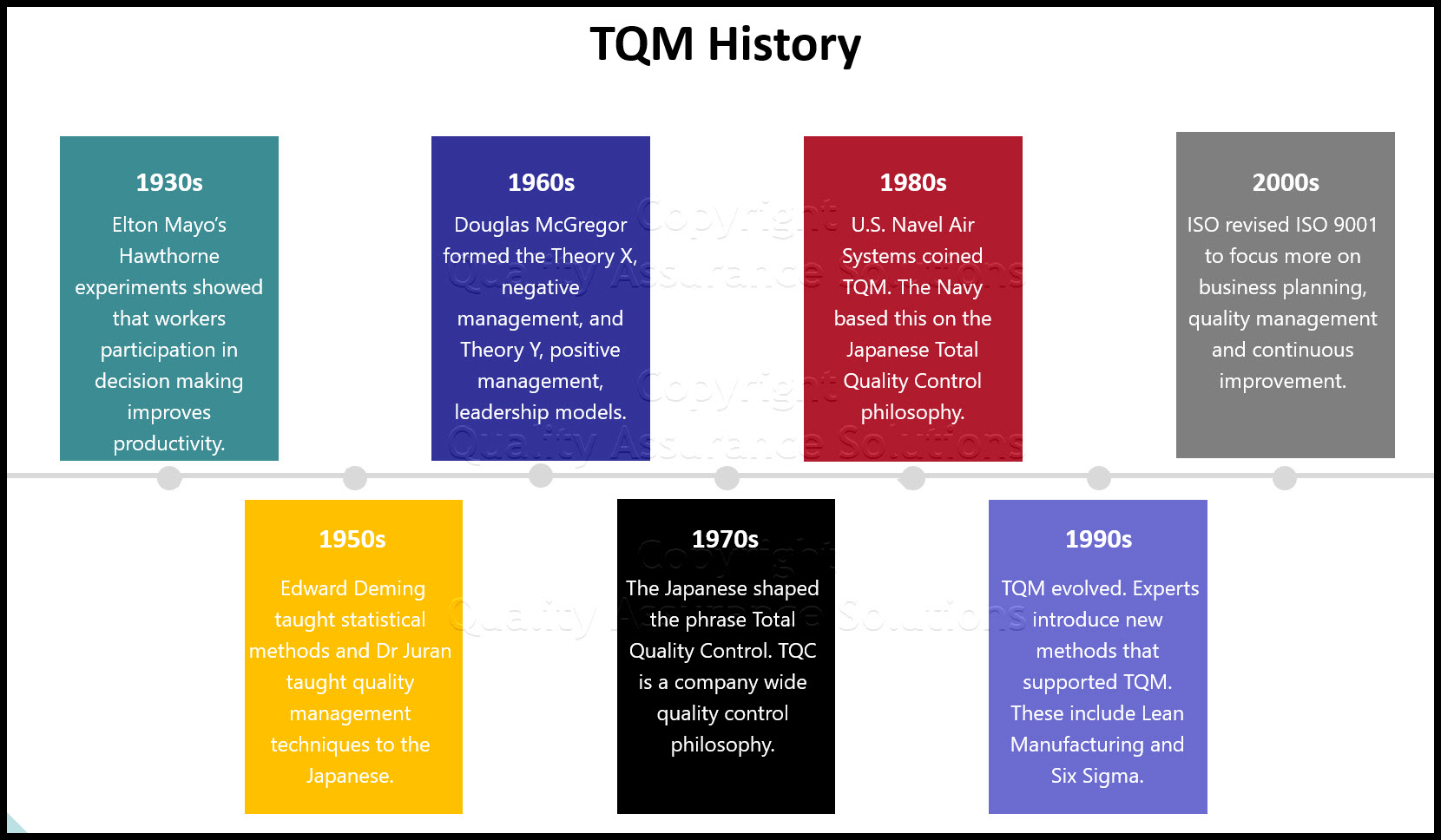

1930s TQM history

The history of TQM starts with Elton Mayo’s Hawthorne experiements from 1927 through 1932. These experiments showed that workers participation in decision making improves productivity.

In the 1930s, the Hawthorne plant of the Western Electric Company studied lighting levels, workday lengths, and rest period lengths to maximize productivity. During the lighting level studies, researchers found that when the lights were brighter, worker productivity increased. However when lighting level was decreased worker productivity also increased.

This change in behavior from the employees is now called the Hawthorne effect. It basically states that when workers are involved in studies or decision making, productivity increases.

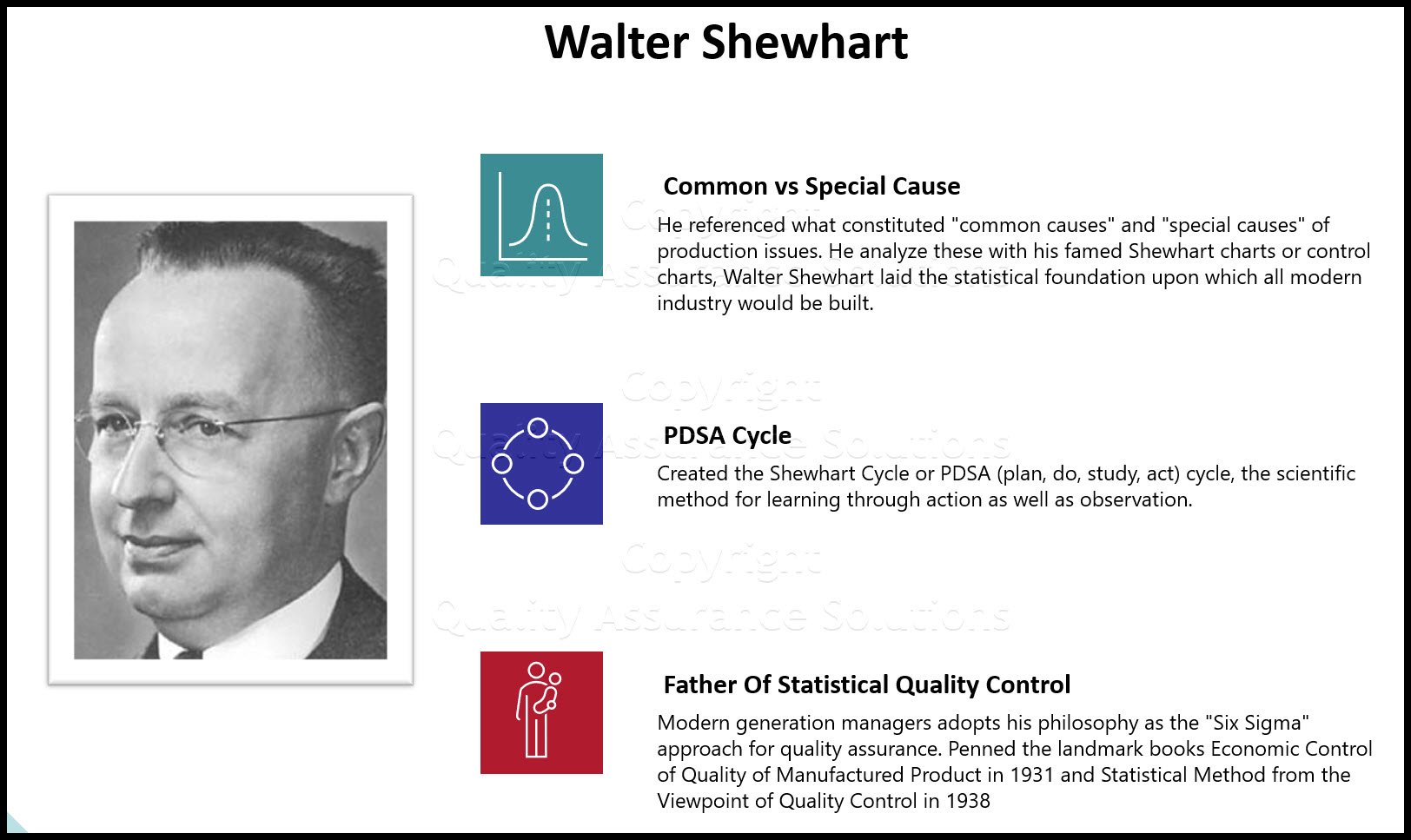

Also during the 1930s, Walter Shewhart developed control charts. which are a statistical method to control processes.

This Data Analysis Video teaches you the basic tools for understanding, summarizing, and making future predictions with your collected data. Includes MS Excel templates.

1950s TQM History

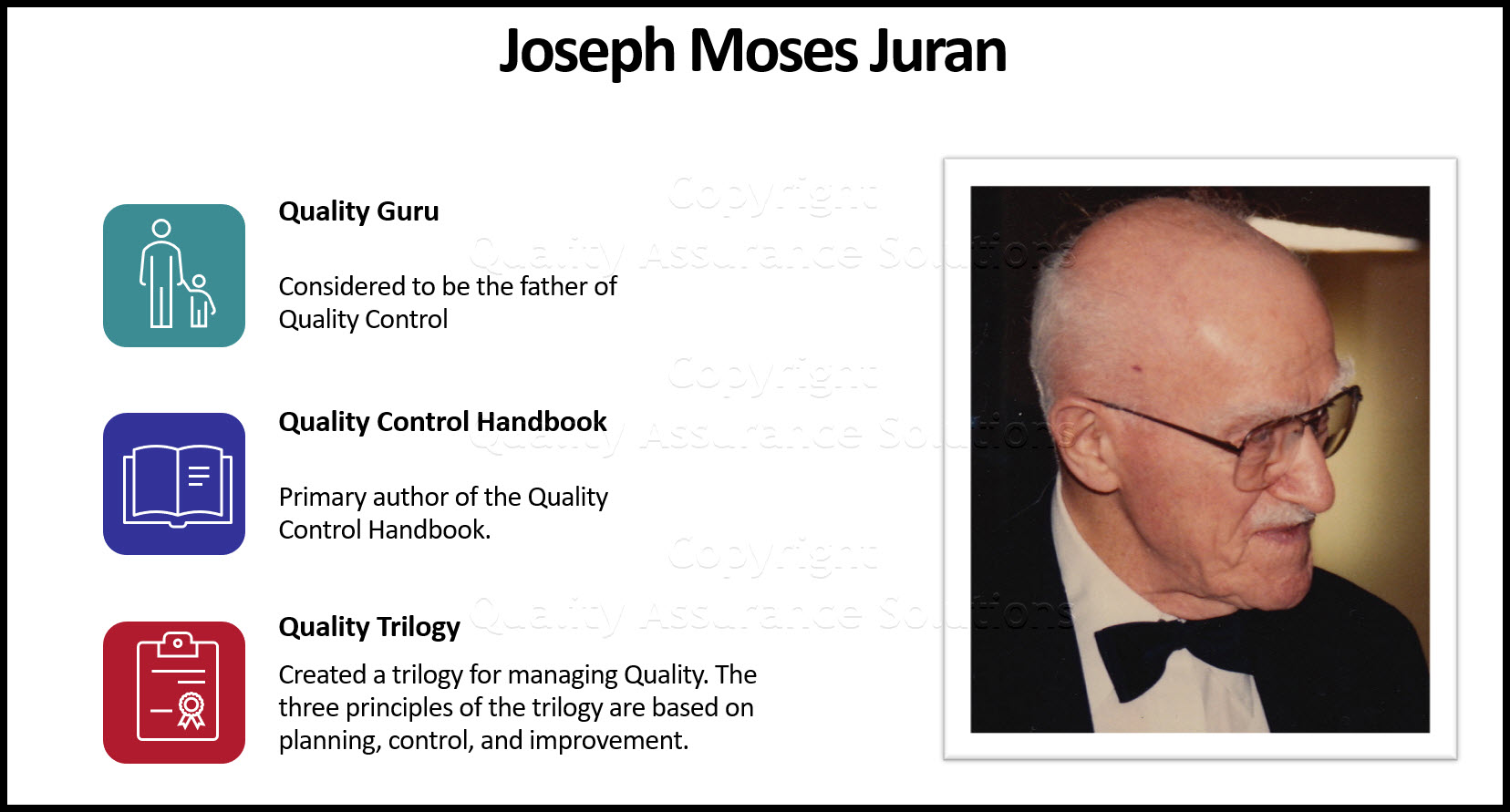

In the 1950s Edward Deming taught statistical methods and Dr Juran taught quality management techniques to the Japanese.

Armand Feigenbaun wrote Total Quality Control. This became the first work that started many Total Quality Management theories.

In 1954 Abraham Maslow created a pyramid of self actualization needs. In terms of work productivity, the lower levels of needs must be met prior to employees performing at higher levels. The needs in order are

- Physiological which is to eat, sleep, and have shelter

- Safety which is to have economic and physical security

- Belonging which is to be accepted by family and friends

- Esteem which is to be held in high regard

- Self actualization which is to achieves ones best

1960s TQM History

In the 1960s Douglas McGregor formed the Theory X and Theory Y leadership models.

A Theory X leader applies a negative approach to management. They assume most workers really do not like to work and try to avoid work.

A Theory Y leader believes workers want to do a good job. They believe workers will offer solutions to problems and participate in problem solving events. An involved employee is a productive employee.

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

1970s History of TQM

In 1968 the Japanese shaped the phrase Total Quality Control. TQC is a company wide quality control philosophy. This philosophy drove Japan to the world quality leader in the 1970s. For the most part, Japan remains the quality leader. However the world has significantly closed the gap.

1980s History of TQM

In the 1980 the U.S. Navel Air Systems coined the TQM phrase. The Navy based most of the principles on the Japanese Total Quality Control philosophy.

Many companies adopted TQM during the 80s. TQM spread like wild fire. Many companies saw significant gains in productivity. However many companies started the program and failed miserably because they weren't willing to change.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

1990s History of Total Quality Management

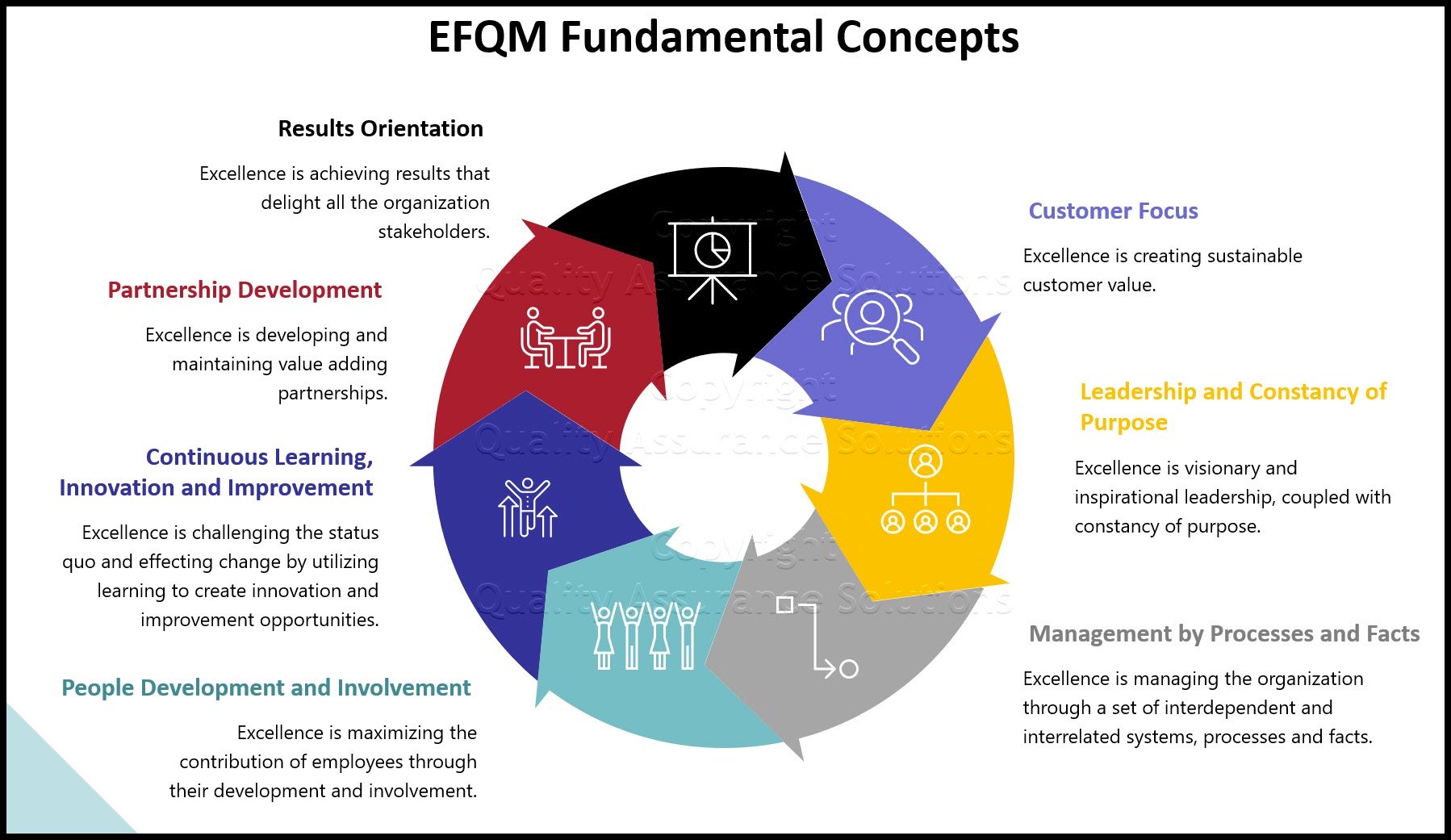

In the 1990s' TQM evolved. Experts introduce new methods that supported TQM. These include Lean Manufacturing and Six Sigma.

Organizations could now become certified to ISO 9001

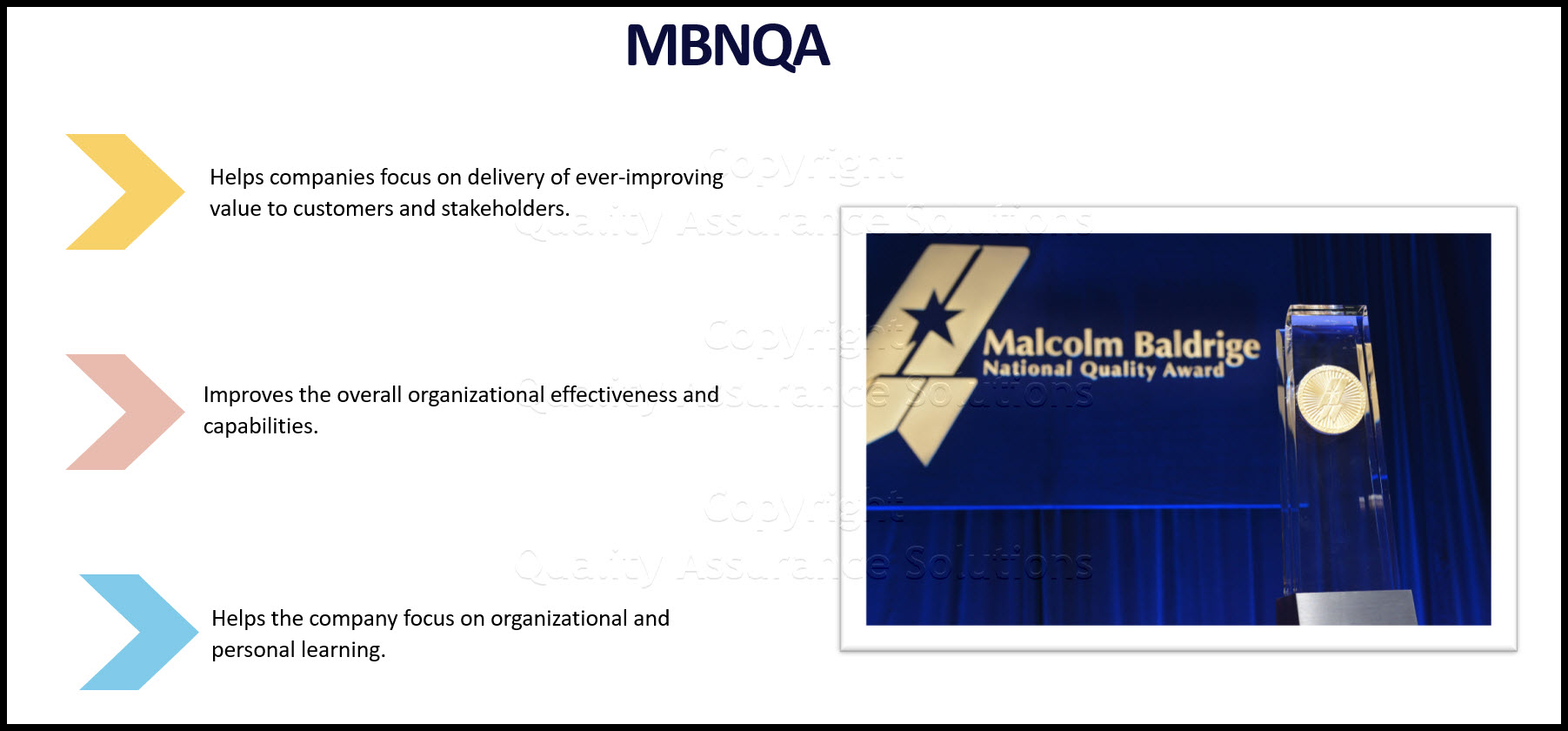

The Malcom Baldridge National Quality Award (MBNQA) was created for the US. MBNQA auditors give this award to companies who show the most outstanding quality management practices.

2000s History of Total Quality Management

In the 2000s, ISO revised ISO 9001 to focus more on business planning, quality management and continuous improvement. Other certification standards were created including AS9100 for aerospace, TS16949 for automotive, ISO 14001 for environmental, TL9000 for electronics, and ISO 17025 for laboratories. These standards all include the ISO 9001.

2010s History

ISO revised the ISO 9001 standard in 2015 to include Knowledge management. Although Six Sigma started in the 1990s, it became the prevalent problem solving process used by Quality professionals.

The term Lean Six Sigma was born. A combination of Lean thinking, 5S, and Six Sigma forms the core of Lean Six Sigma. In addition experts start using Kaizen, Gemba, and Hoshin Kanri concepts.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

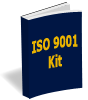

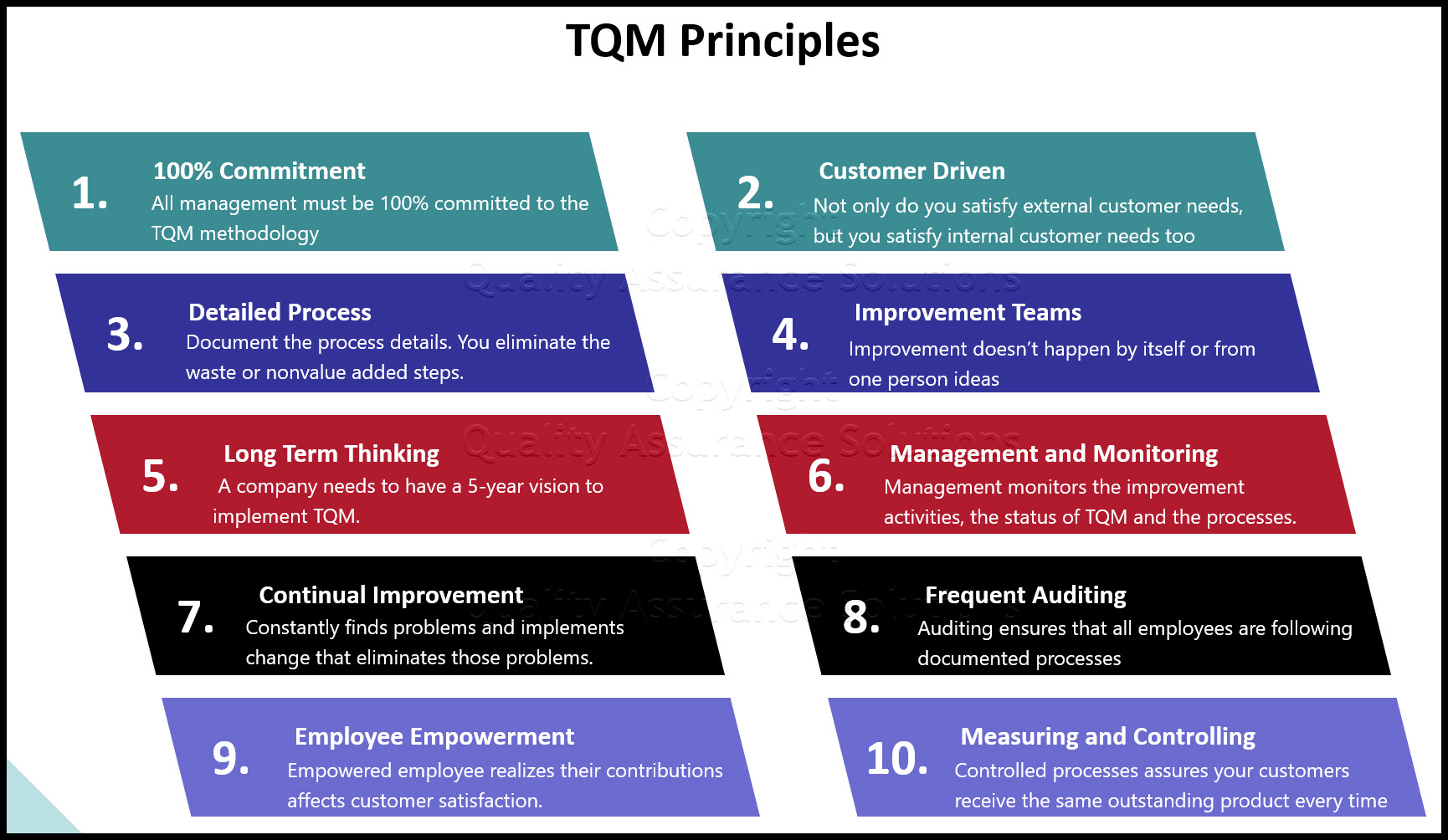

Key Concepts of Total Quality Management include

- structured system for exceeding customer expectations

- system that empowers employees

- drives higher profits

- drives lower costs

- continuous improvement.

- management centered approach on improving quality

Benefits of TQM include

- Improves competitive position

- increase adaptability to global markets

- elevated productivity

- superior global image

- eliminates defects

- significantly reduces waste.

- reduces quality costs

- Improves management communication

- raises profits

- drives customer focus

- customer loyalty

- reduces design time

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |