Dr Deming Point 3

Cease Dependence on

Mass Inspection

First, A Little Dr. Deming History

Did you know that Dr. Deming once tried to volunteer for USA's National Guard? Since he lived in a small town, Cody Wyoming this was a big deal to the town residents. In 1914, the town had a celebration honoring him and others for joining the National Guard. After the celebration, Dr. Deming went to Cheyenne by train to join the National Guard. The National Guard rejected him because he was too young. He was only 14.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

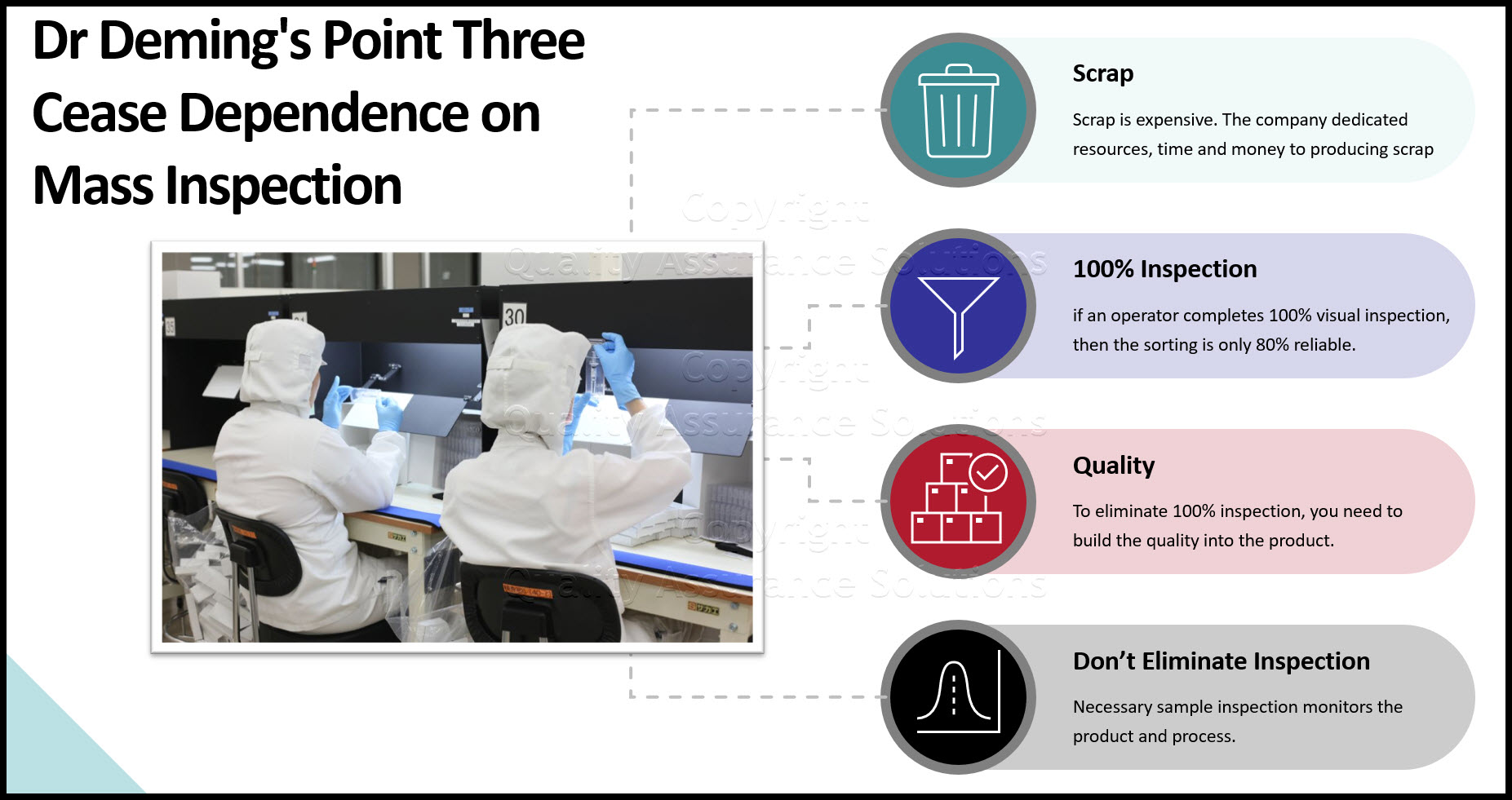

Deming Point 3: Cease Dependence on Mass Inspection

I've seen many companies mass inspect the final product. Parts come into final inspection department. Dedicated inspectors 100% inspect these parts. They sort the parts between good and bad. Because the inspectors sort the parts, senior management thinks the customer is receiving good parts.

There are many problems with this scenario. Scrap is expensive. The company dedicated resources, time and money to producing scrap.

100% inspection does not guarantee that 100% of the product is removed. In fact, if an operator completes 100% visual inspection then the sorting is only 80% reliable. That means the operator will make a mistake 20% of the time. Even with extensive operator training that number could only be reduce to 5%.

How do you eliminate 100% inspection? First you need to build the quality into the product. This starts at the very beginning of the design stage. If production is past the design stage, you can use pareto charts to classify the top defects. Focus on eliminating the top defects. Use the 8D problem solving approach to reduce the defects.

This does not mean that the goal is to completely remove all inspection. Necessary sample inspection monitors the product and process. Dr. Deming would say "Don't drive at night without your lights on". In addition, 100% inspection may be initially required when there is a change in the process or materials.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Dr Deming’s 14 points

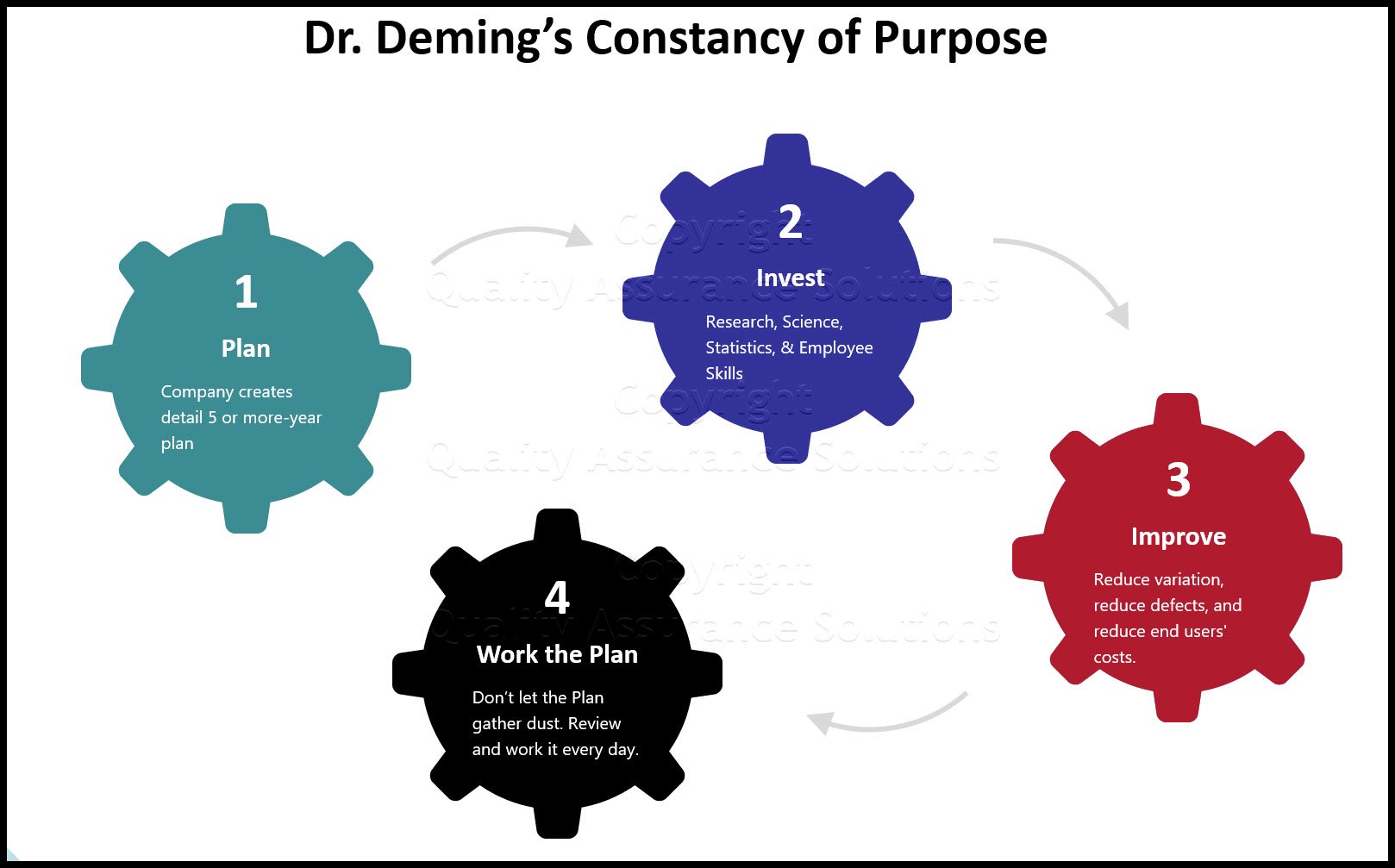

1. Create constancy of purpose for improvement of product and service.

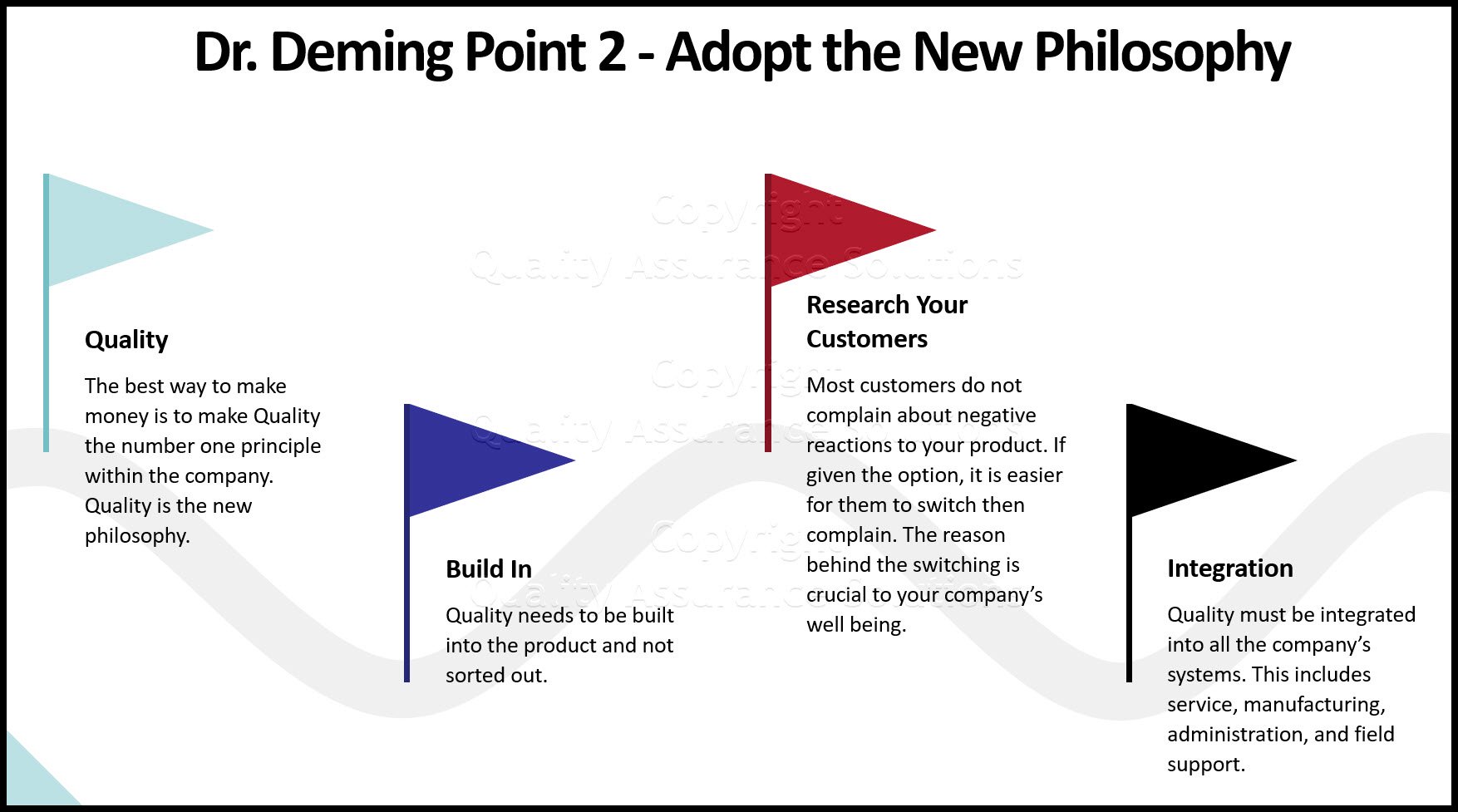

2. Adopt the new philosophy

3. Cease dependence on mass inspection

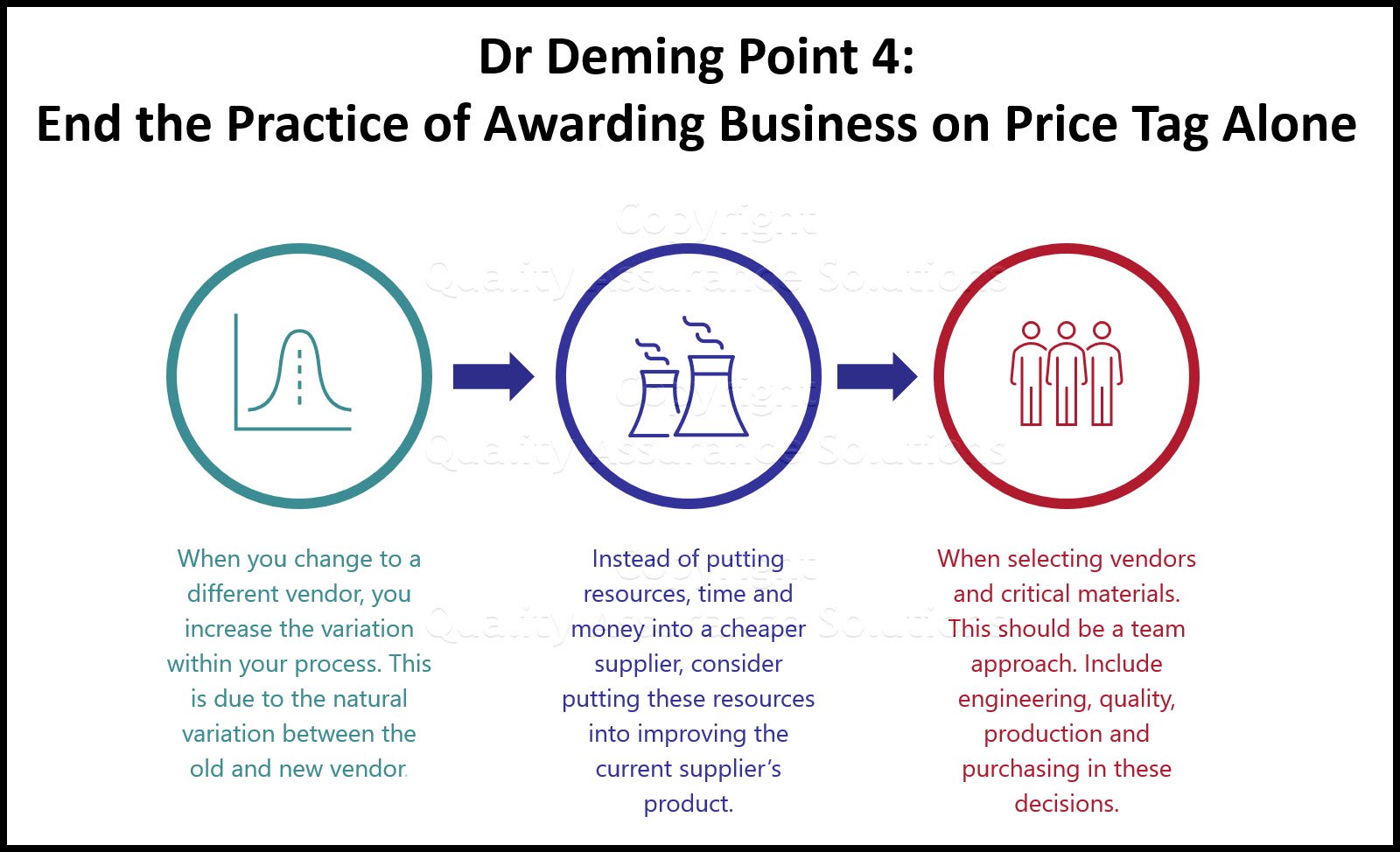

4. End the practice of awarding business on price tag alone

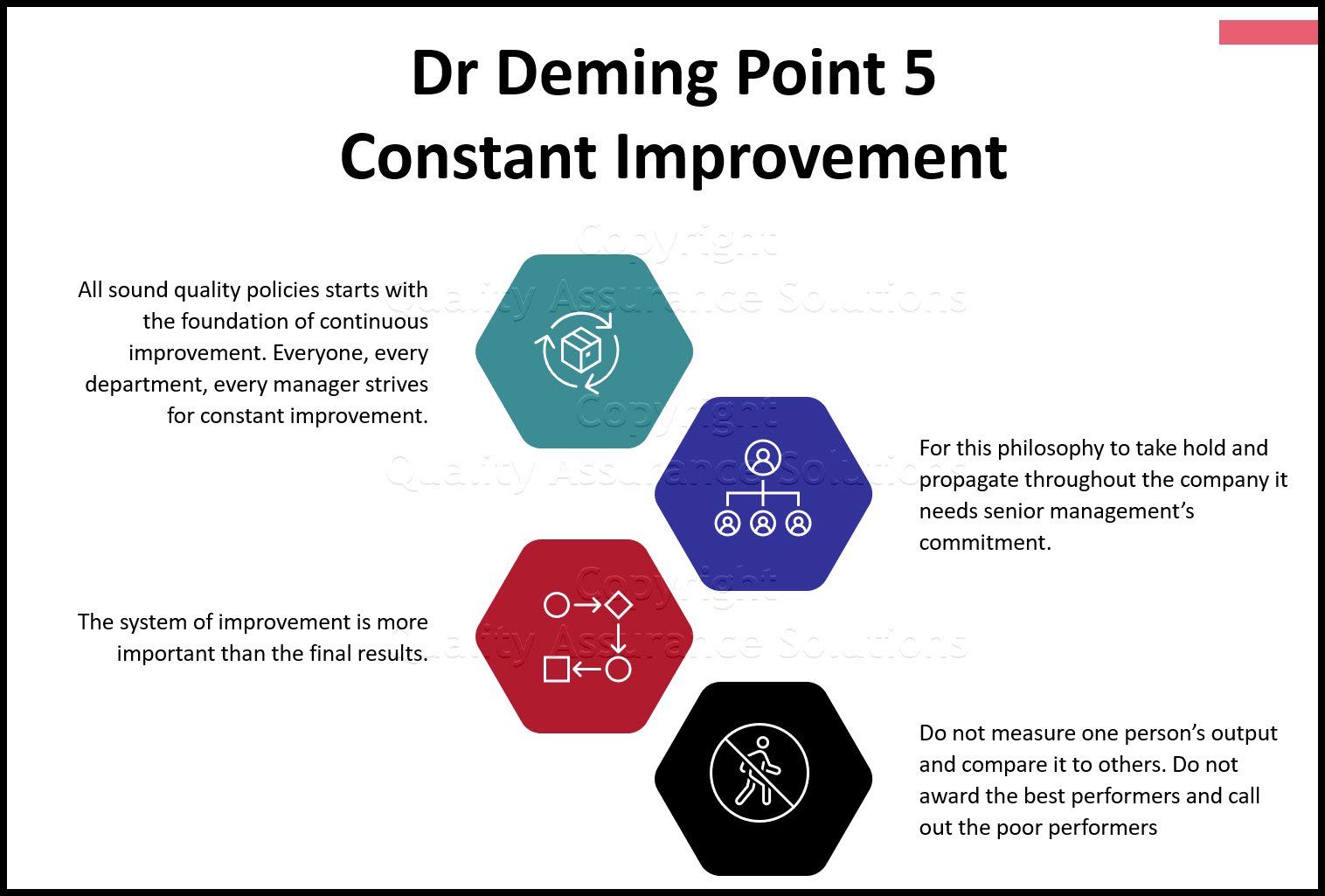

5. Improve constantly and forever the system of production and service.

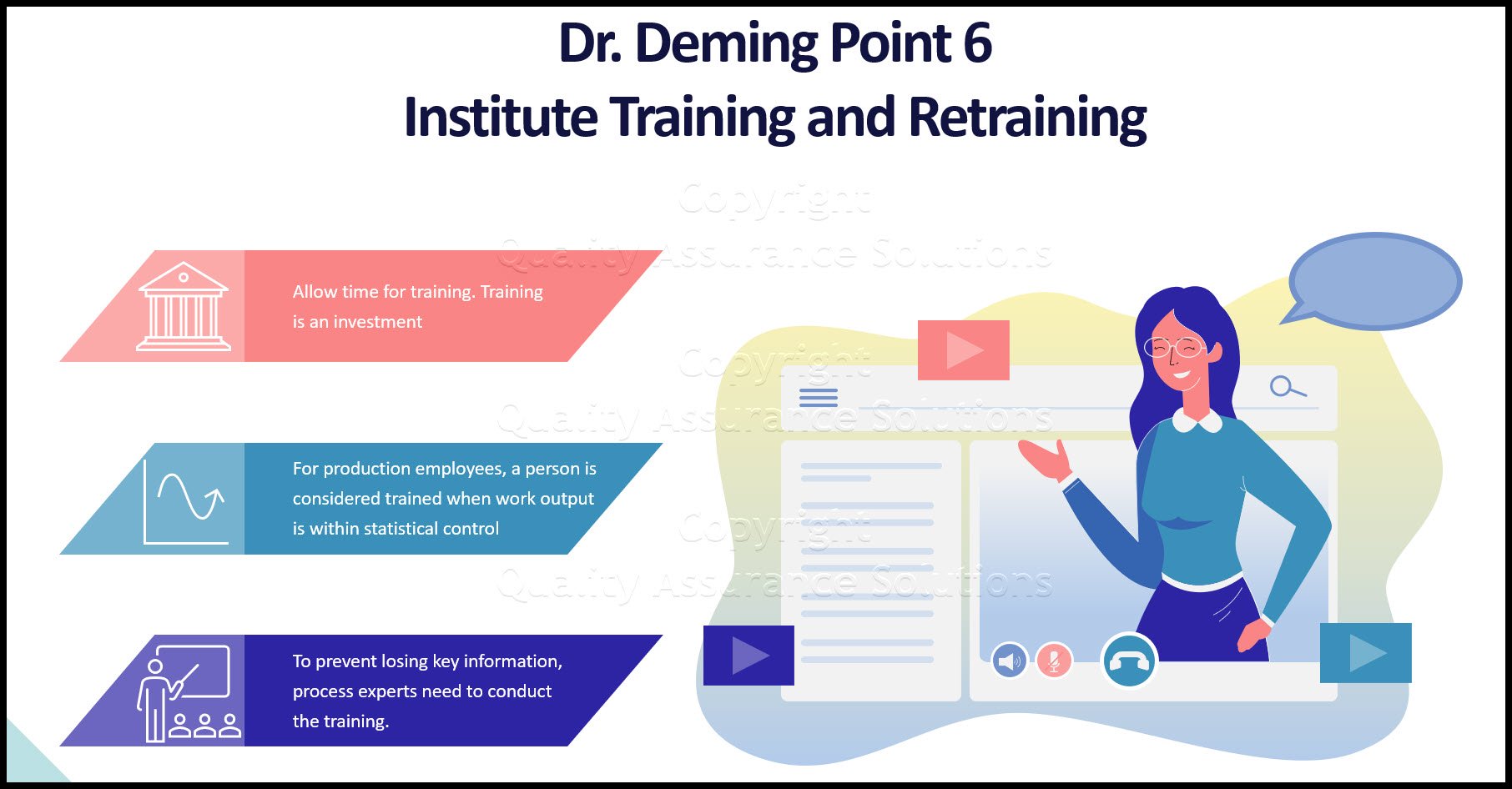

6. Institute training

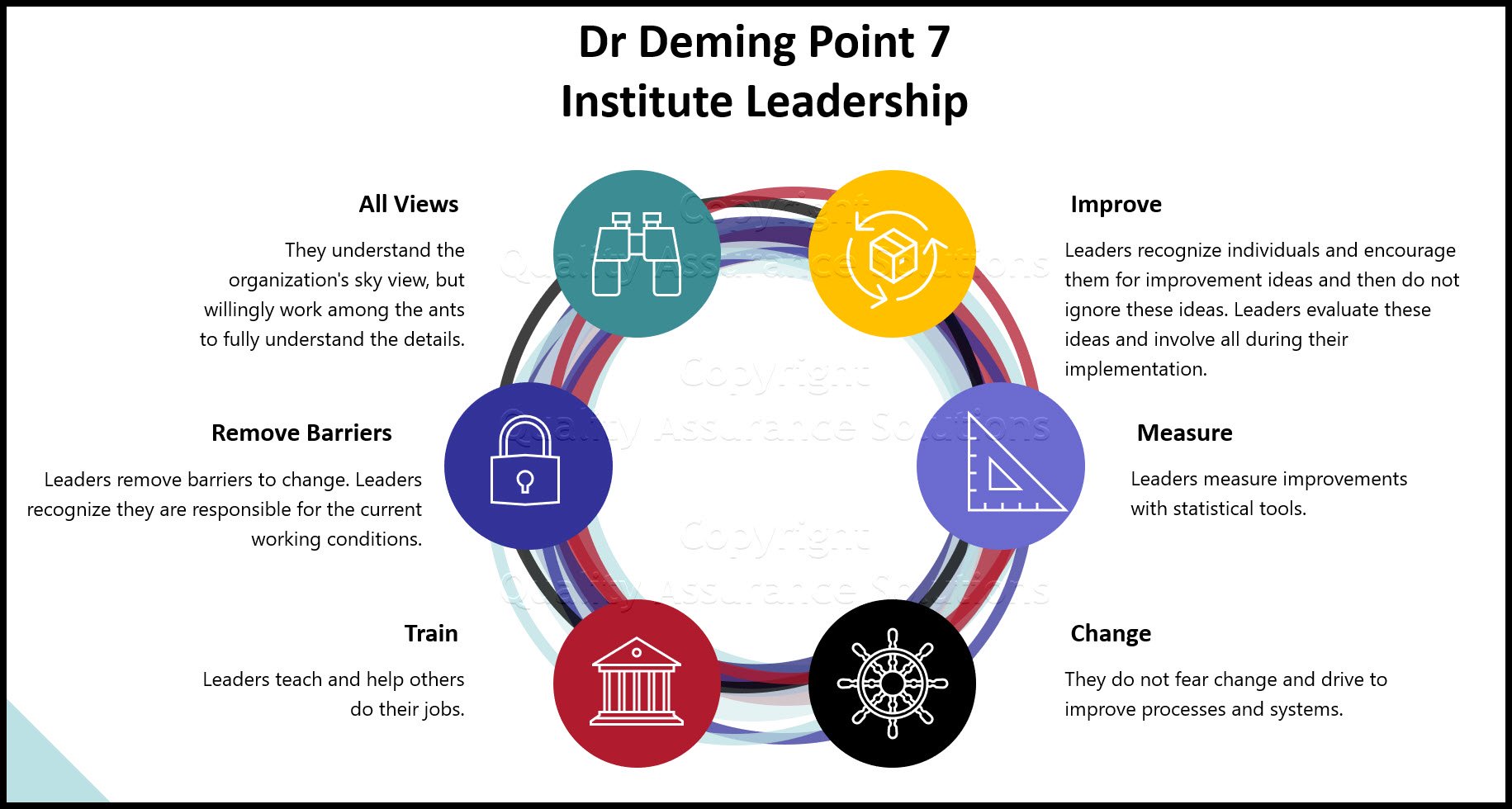

7. Institute leadership

8. Drive out fear

9. Break down barriers between staff areas

10. Eliminate slogans, exhortations, and targets for the workforce.

11. Eliminate numerical quotas.

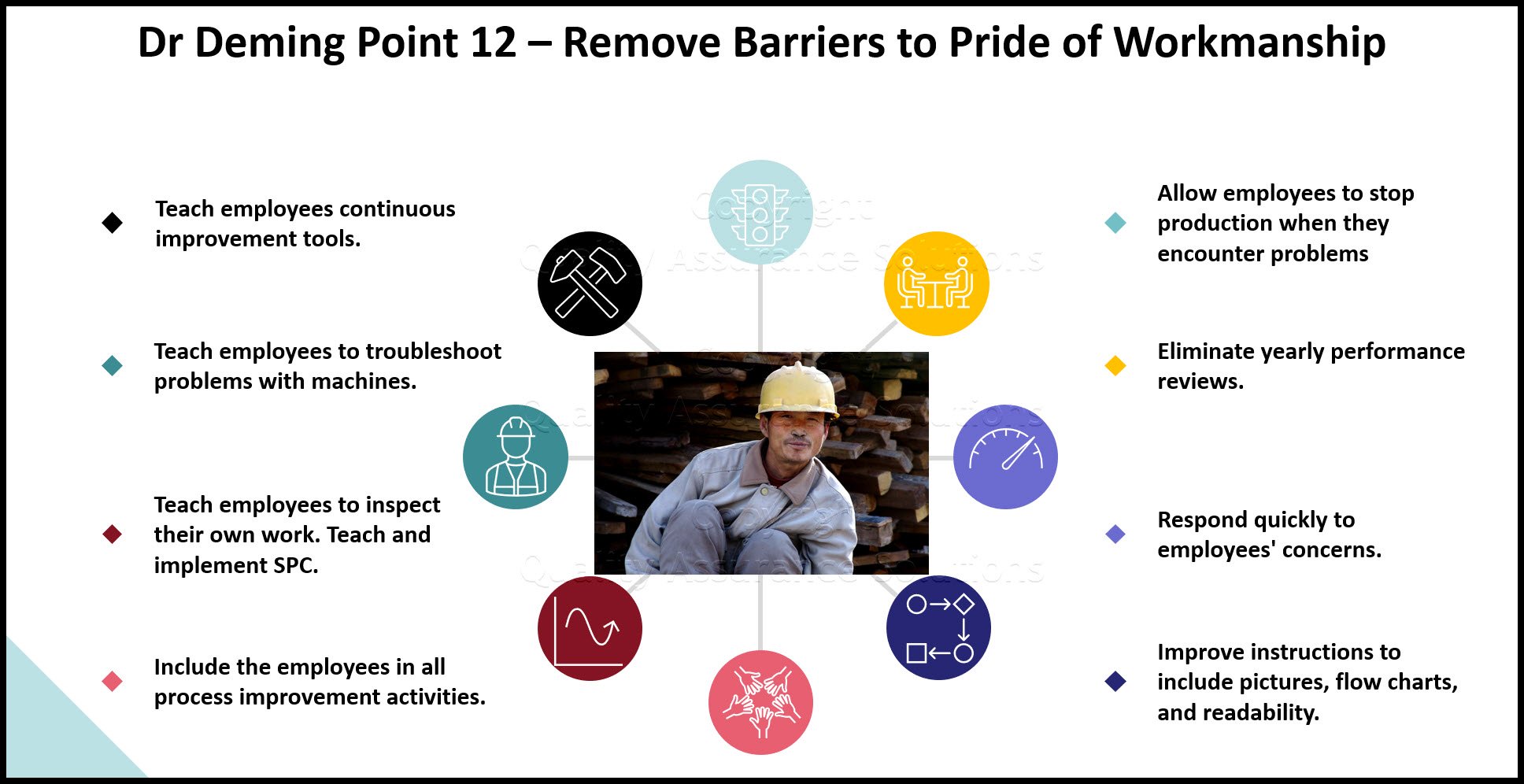

12. Remove barriers to pride of workmanship.

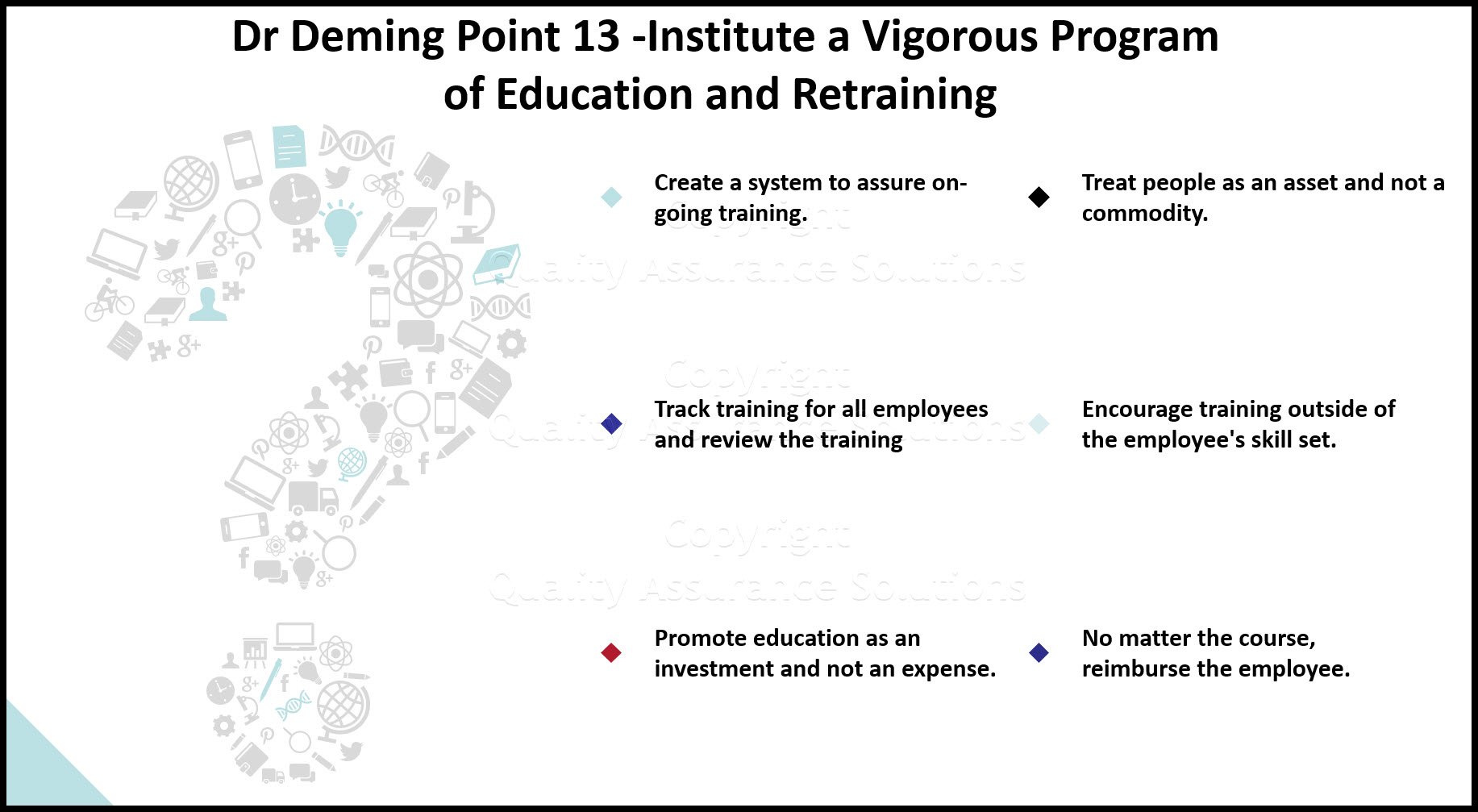

13. Institute a vigorous program of education and retraining.

14. Take action to accomplish the transformation.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |