TQM Methodology

This page describes the TQM Methodology or the principles of TQM

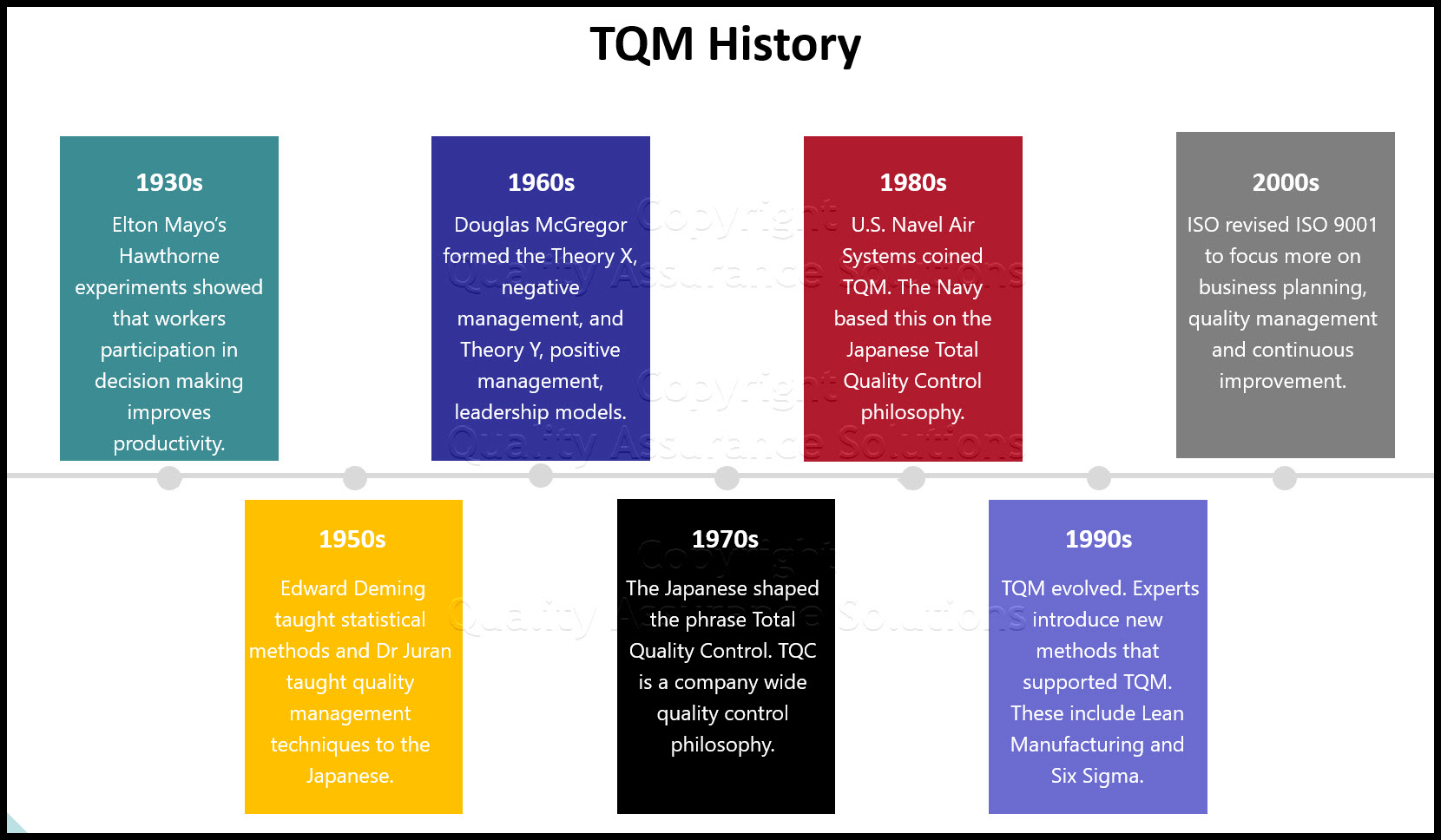

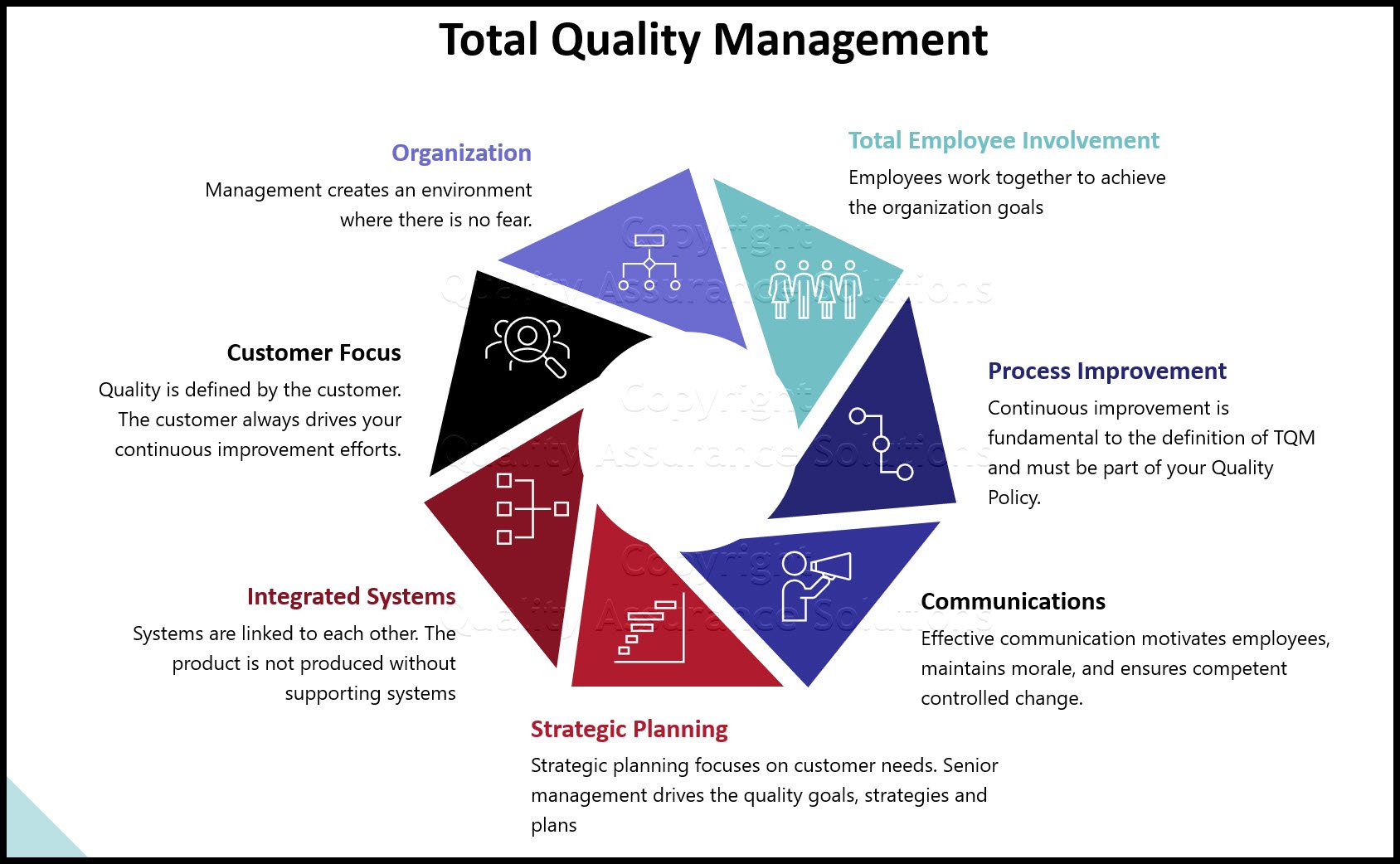

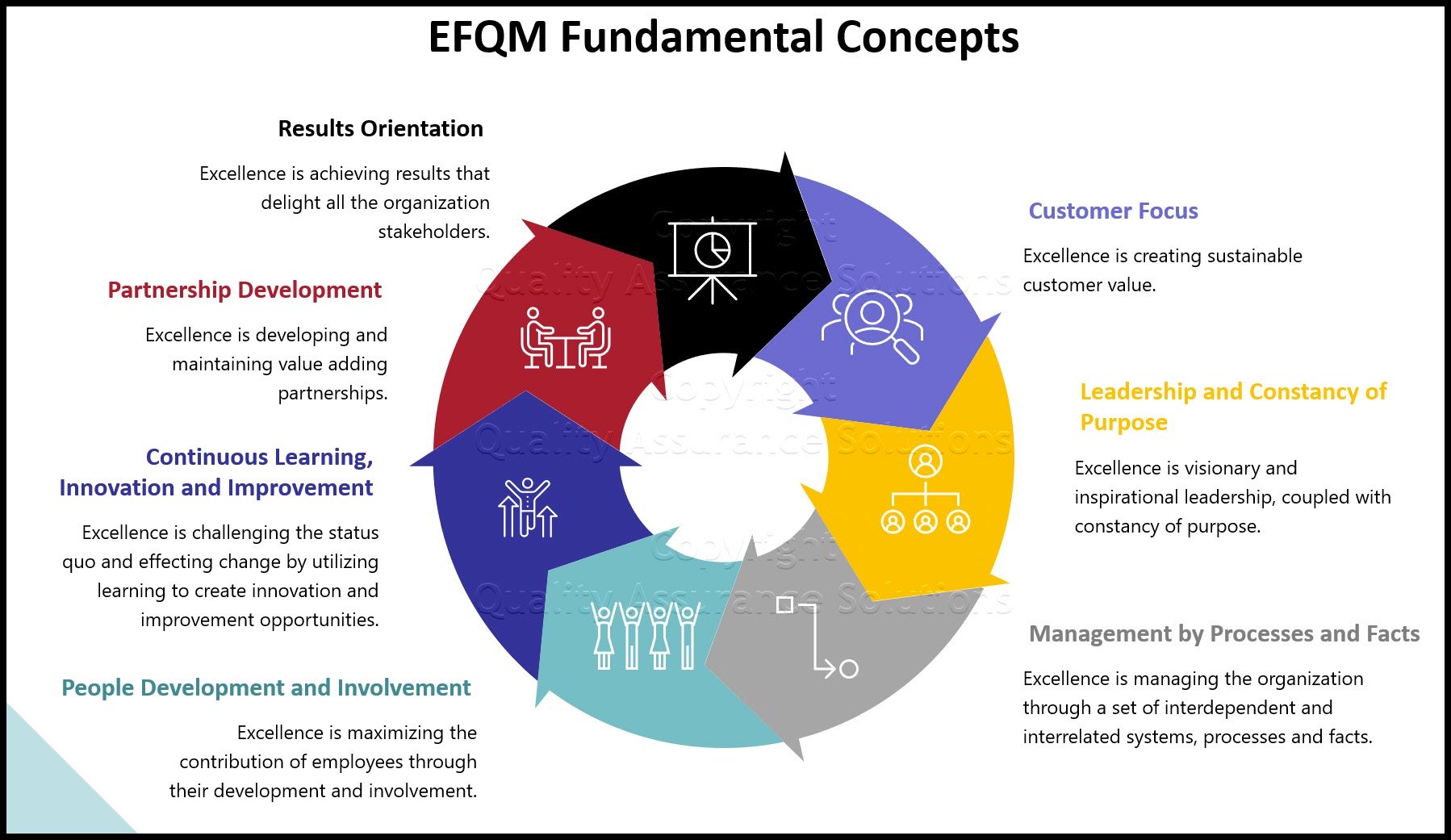

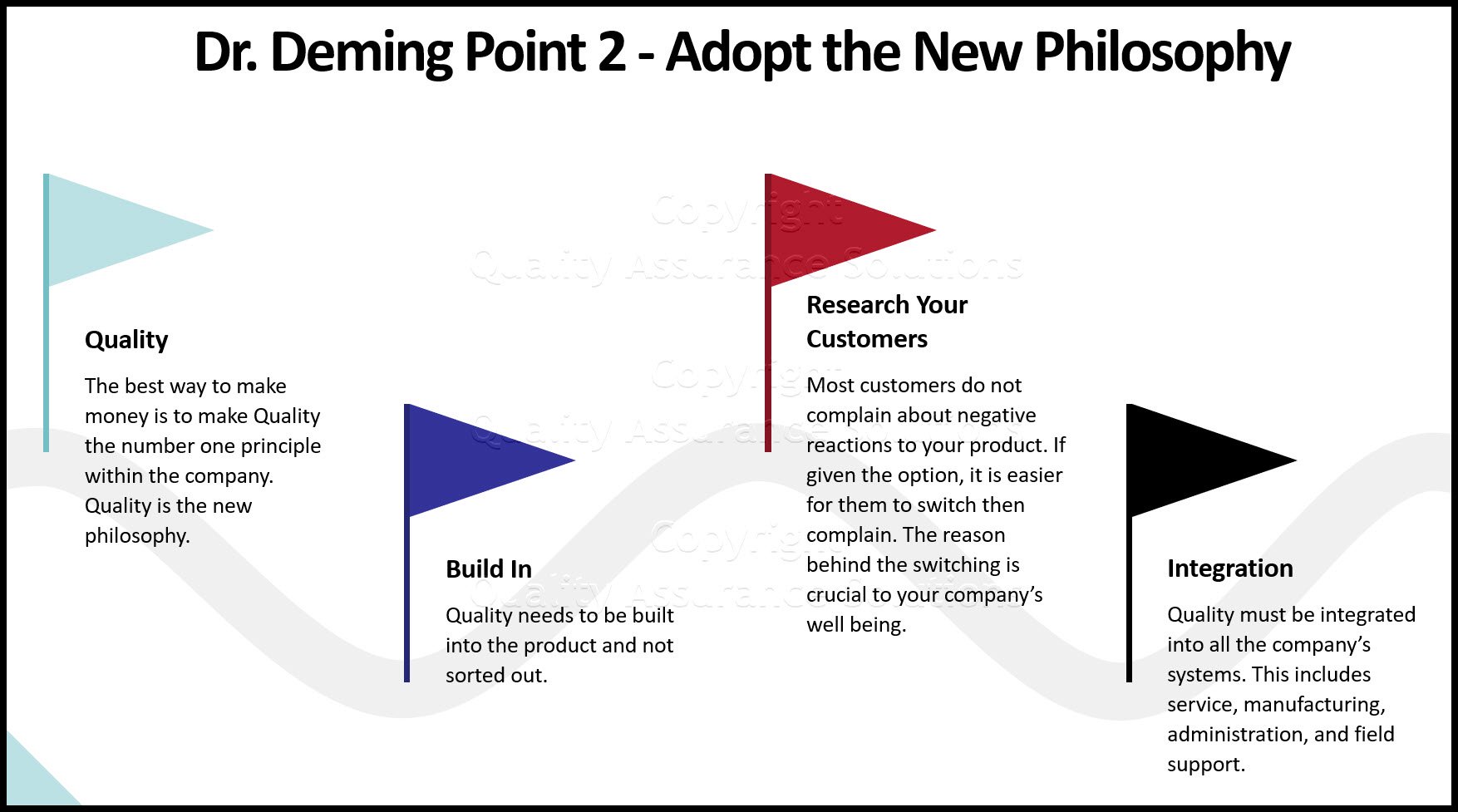

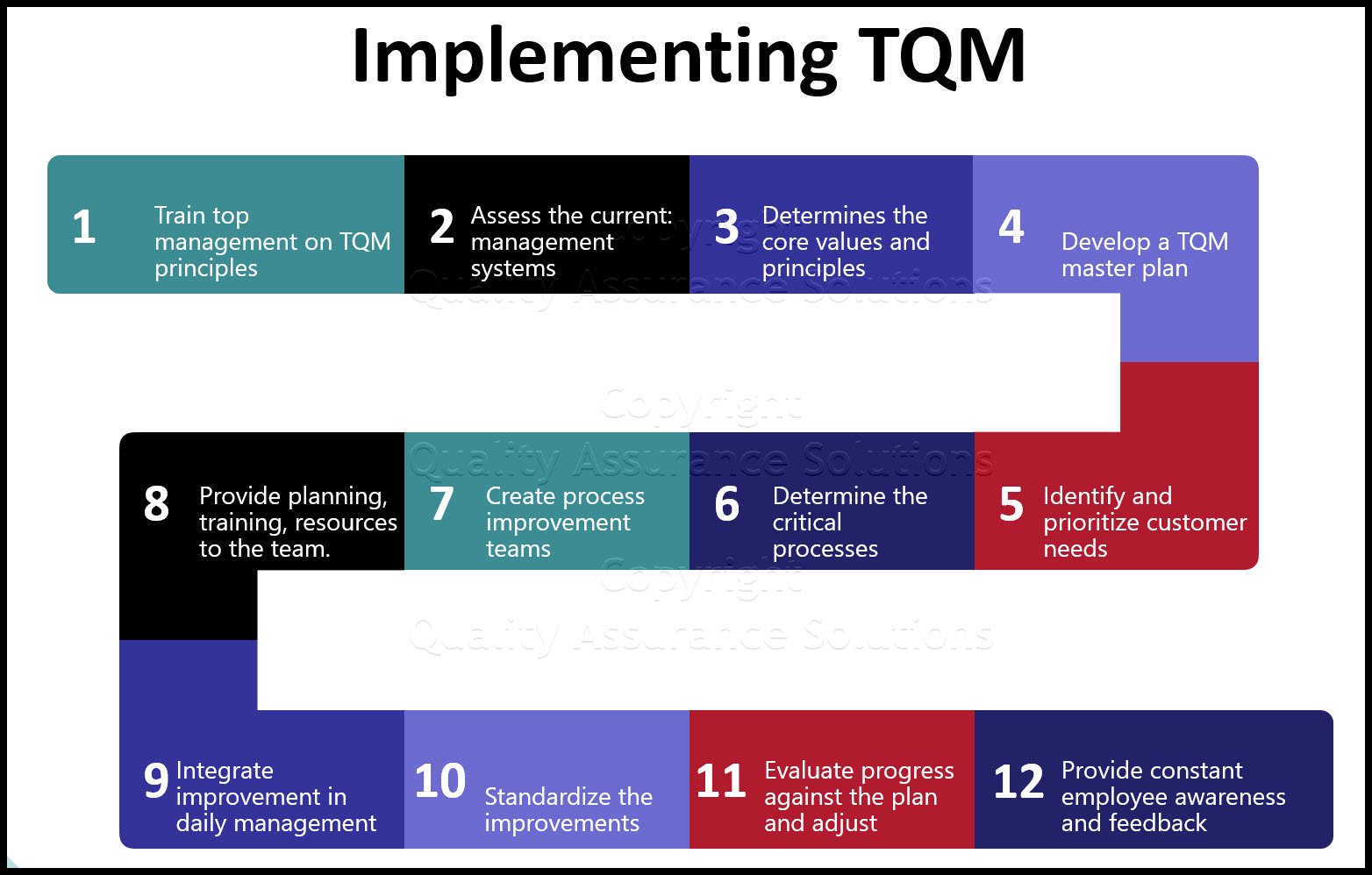

Total Quality Management (TQM) is a company wide philosophy that focuses on customer satisfaction. Every business improvement, quality improvement, or continuous improvement process is part of TQM Methodology.

TQM is not a flavor of the month management. When you are a TQM organization, you breathe TQM. I find TQM companies do not just discuss TQM, they walk TQM. They live TQM. When you apply the principles of TQM, TQM is inherent to all management decisions.

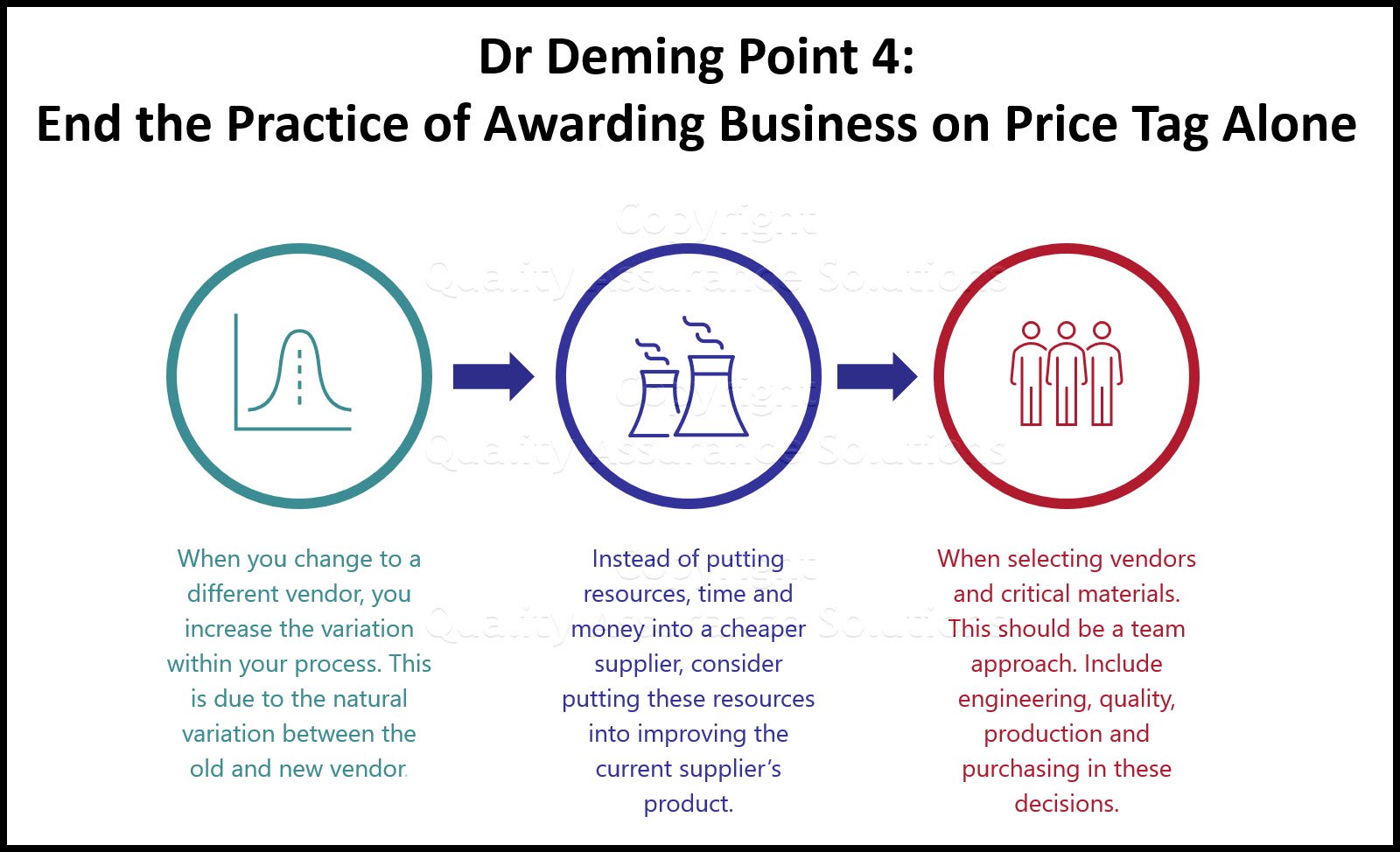

A TQM company understands their customers and needs. A TQM company works with their vendors and teaches them TQM tools. A TQM company constantly trains their employees and helps them improve their lives.

A TQM company thinks long term. Short term profits are not the immediate concern. Customer satisfaction is the focus. Customers included both external, internal, stake holders and share holders.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

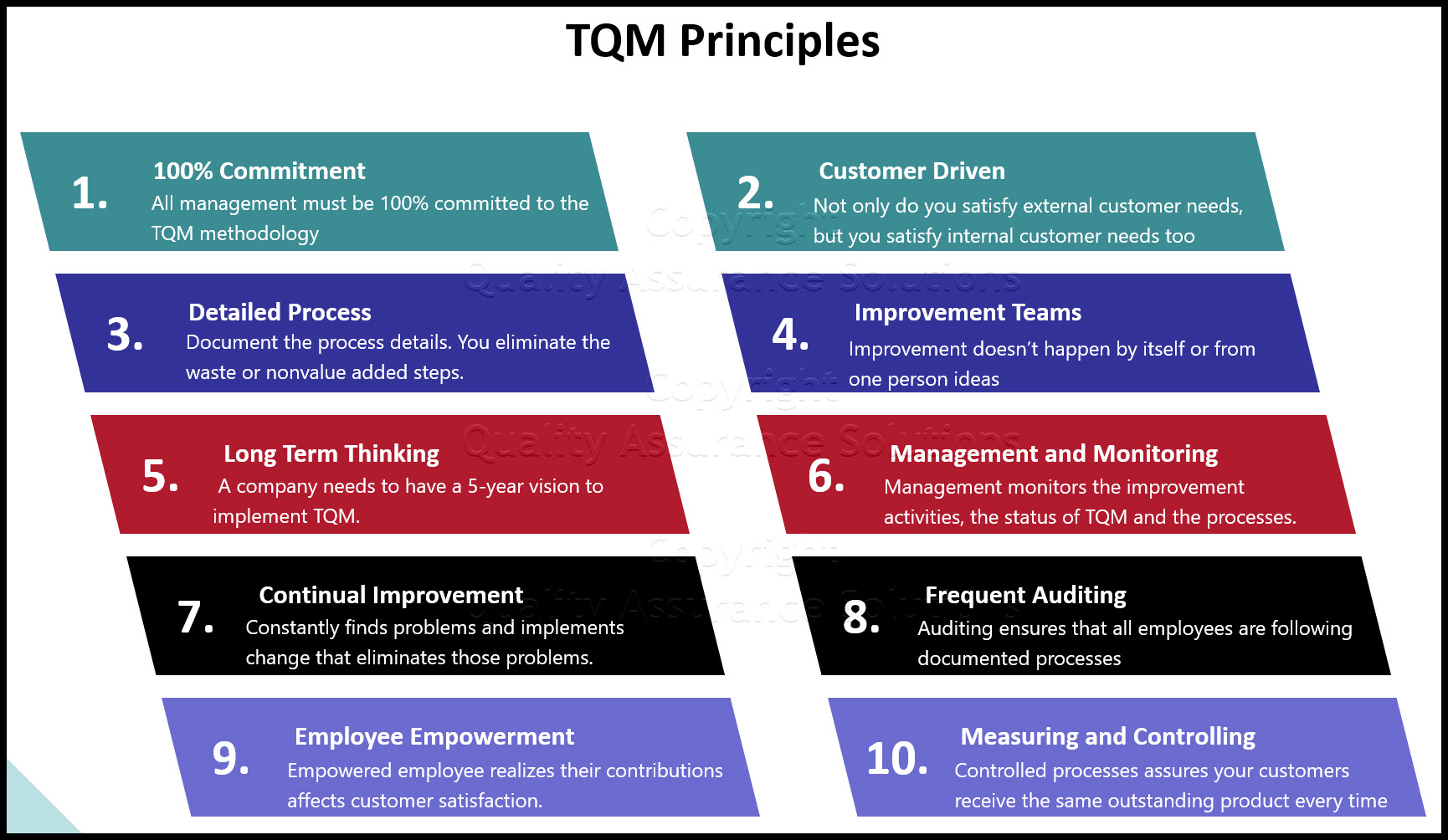

10 Principals of TQM Methodology

- 100% Commitment

- Customer Driven

- Detailed Process

- Improvement Teams

- Long Term Thinking

- Management and Monitoring

- Continual Improvement

- Frequent Auditing

- Employee Empowerment

- Measuring and Controlling

Your comprehensive package for learning and training the TRIZ problem solving methodology. Includes mobile app, books, PowerPoints and real world examples.

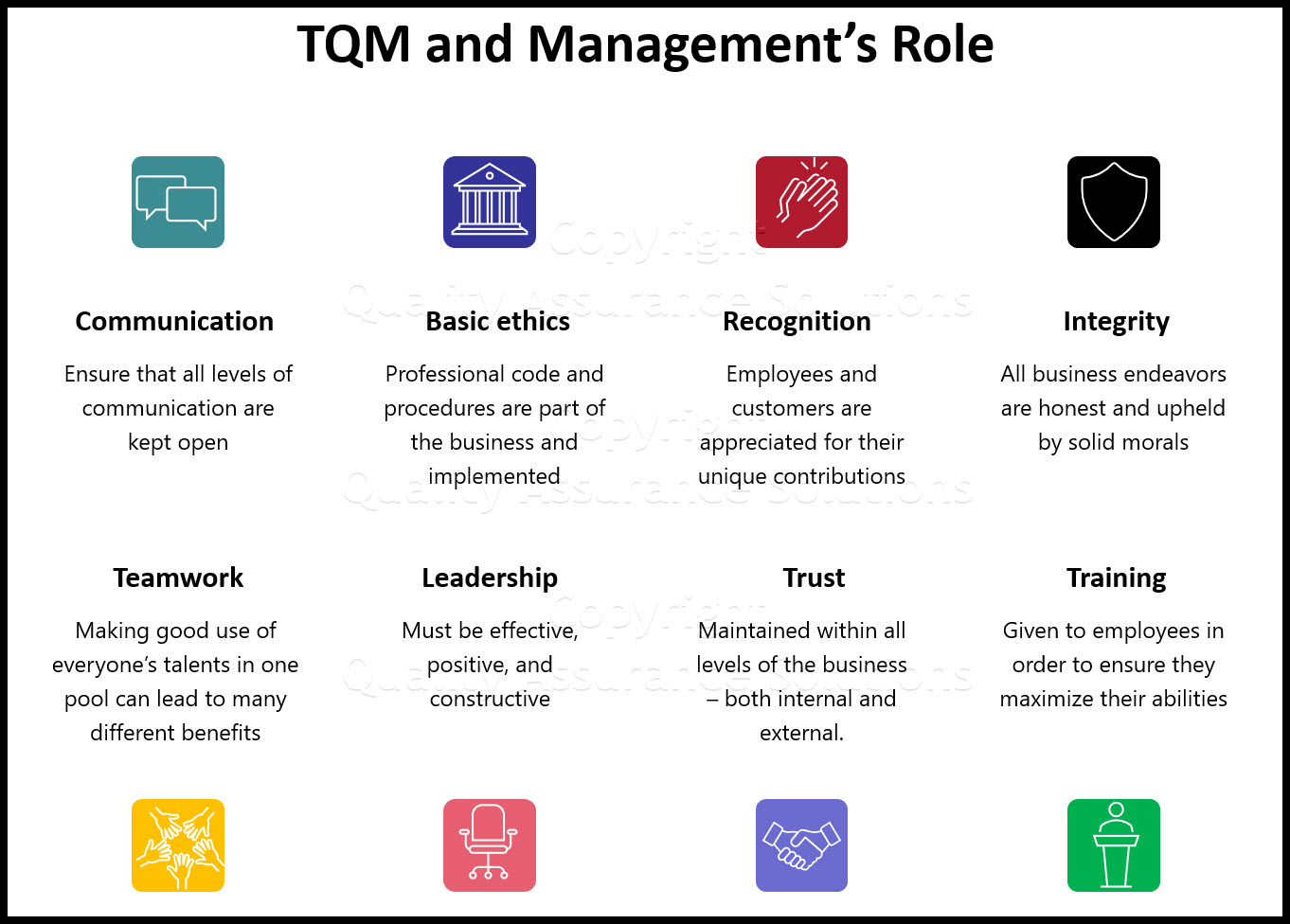

100% Commitment

In order for TQM to work, all management must be 100% committed to the TQM methodology. This includes the most top level person to all line managers. Top management must understand and harness the principles of TQM.

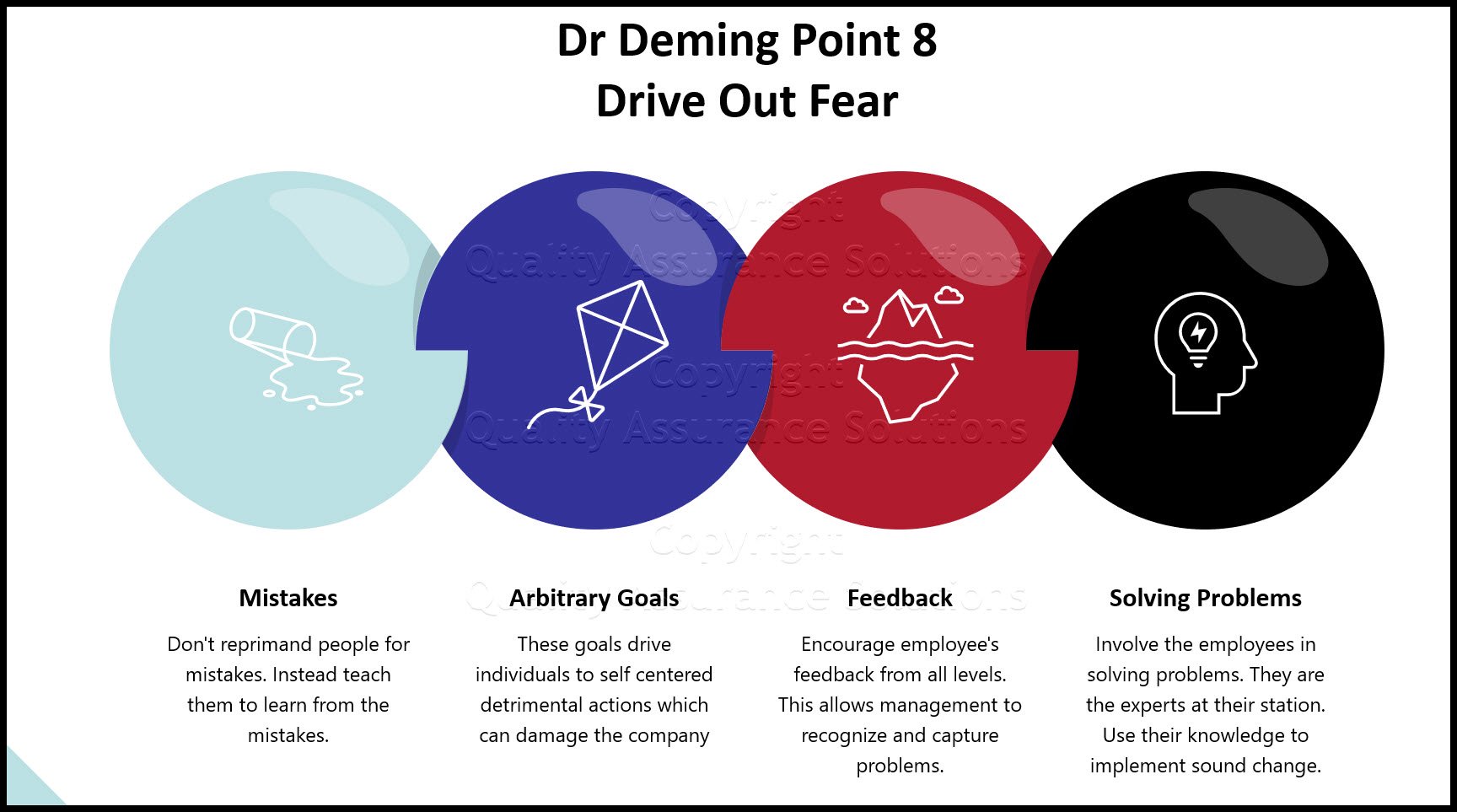

Top Management is responsible for removing fear from the organization’s employees. Employees cannot be fearful of making mistakes. Employees cannot be fearful of making decisions.

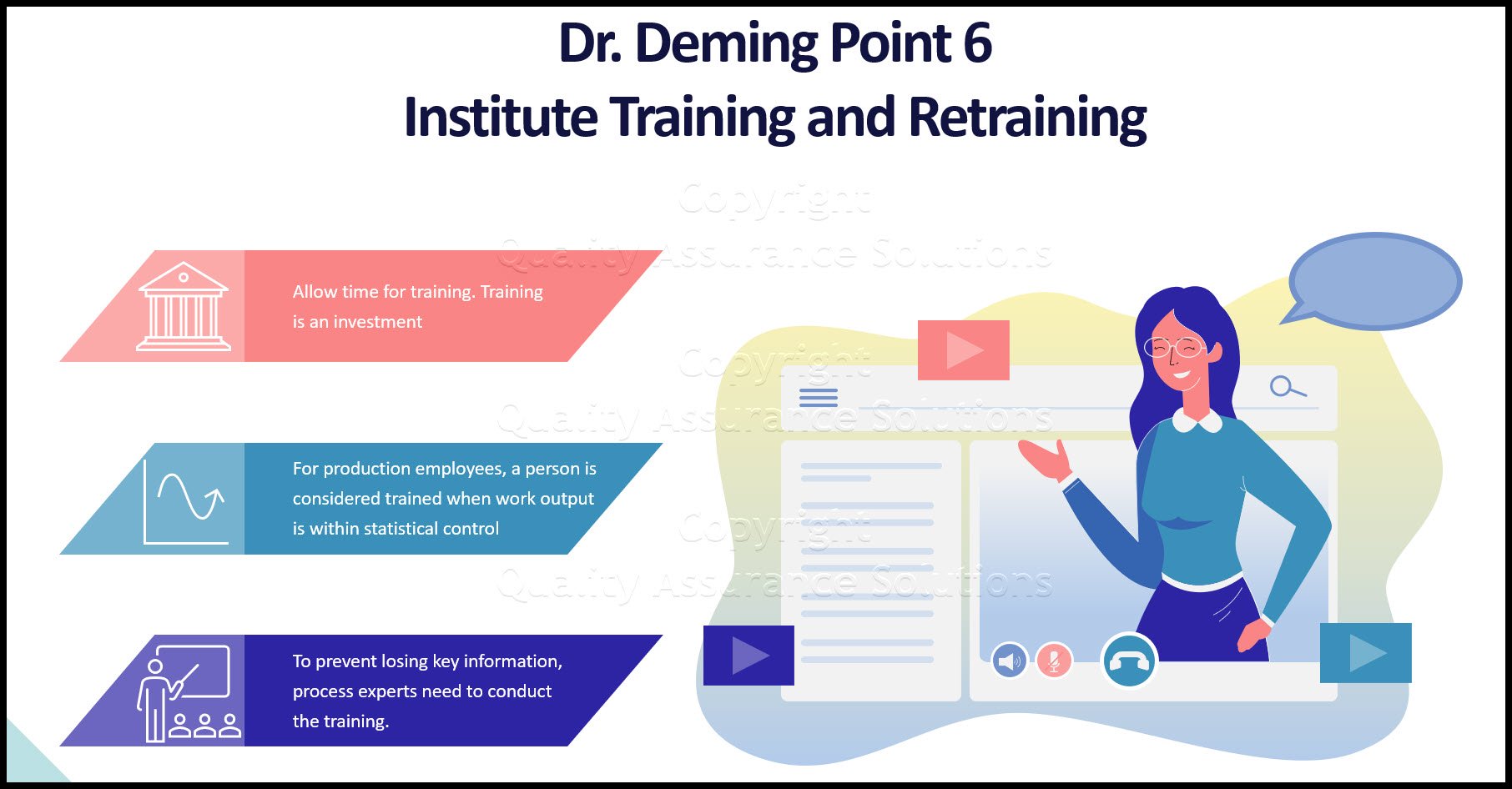

100% commitment means that all management receives training in Total Quality Management tools, teams, continuous improvement, and customer satisfaction. After training, management then trains all other employees. Management should record and track all training in a software package such as TrainingKeeper

Management needs to realize that TQM is an investment, a long term investment. Before making the decision to jump on the TQM bandwagon, get training first. Research TQM thoroughly.

The road to TQM requires hard, hard work. However the benefits are outstanding and long lasting.

Do not make an emotional call based on your organization current situation. Top management must be willing to change. This may include a reorganization. If top management cannot commit, perhaps they are used to their own way, then TQM is not going to work. Is your company willing to put the right people in the right roles to move ahead with TQM?

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Customer Driven

Selling quality products to customers is just a small part of TQM methodology. Your company will need to outstandingly serve the customer. This means many things depending on your customers such as

- Providing information as needed

- Holding the customer hand through installation.

- Creating custom surveys to capture your customer needs

- Constantly improving lead times

- Quickly responding to customer questions.

- Providing detail information on your website

Not only do you satisfy external customer needs but you satisfy internal customer needs too. This means that your employees must be happy and motivated. Include all employees in improvement projects.

Do all employees have the tools, recourses to complete their tasks? Do all employees partake in improvement projects? Have you surveyed the employees to find their needs?

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

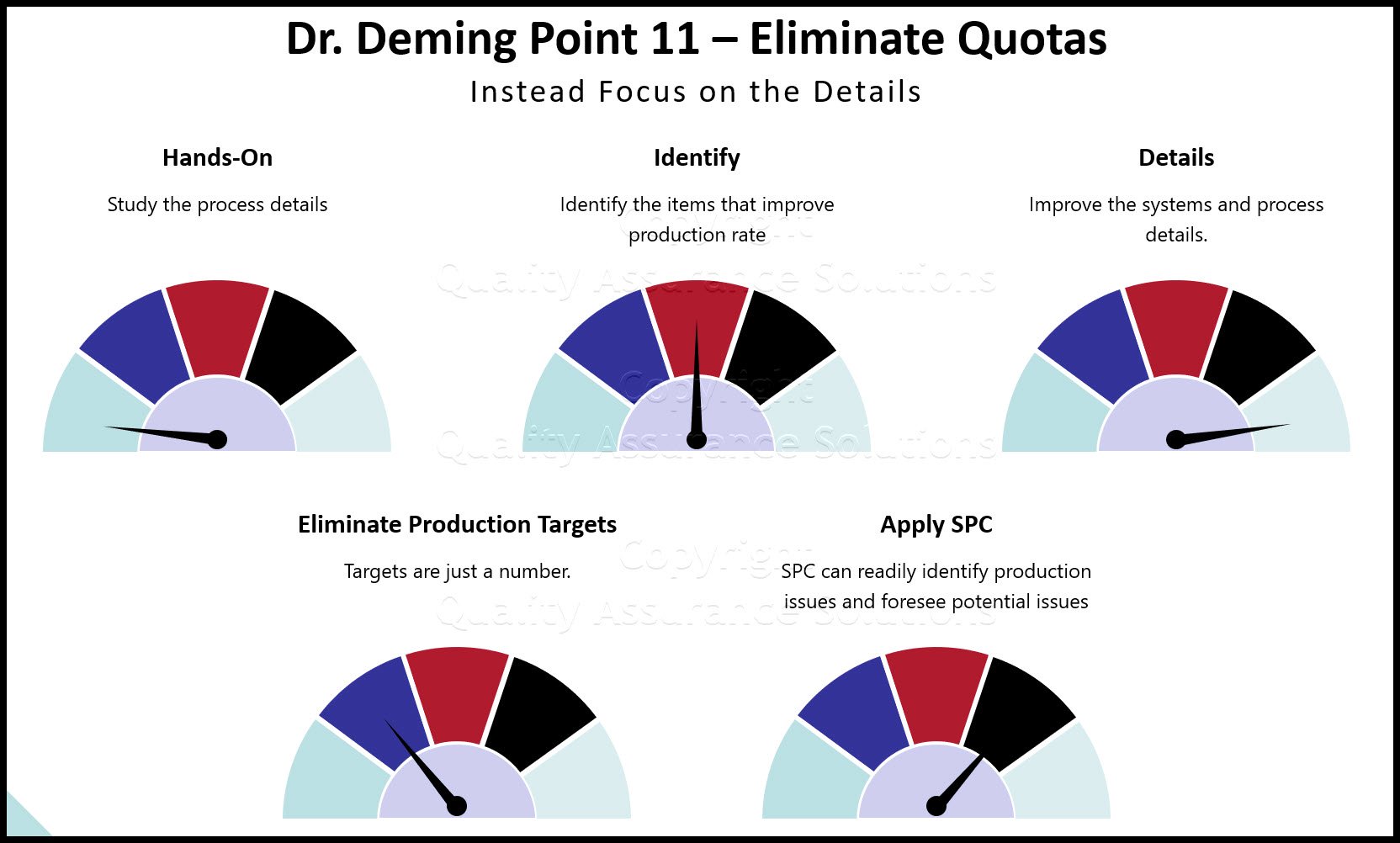

Detailed Process

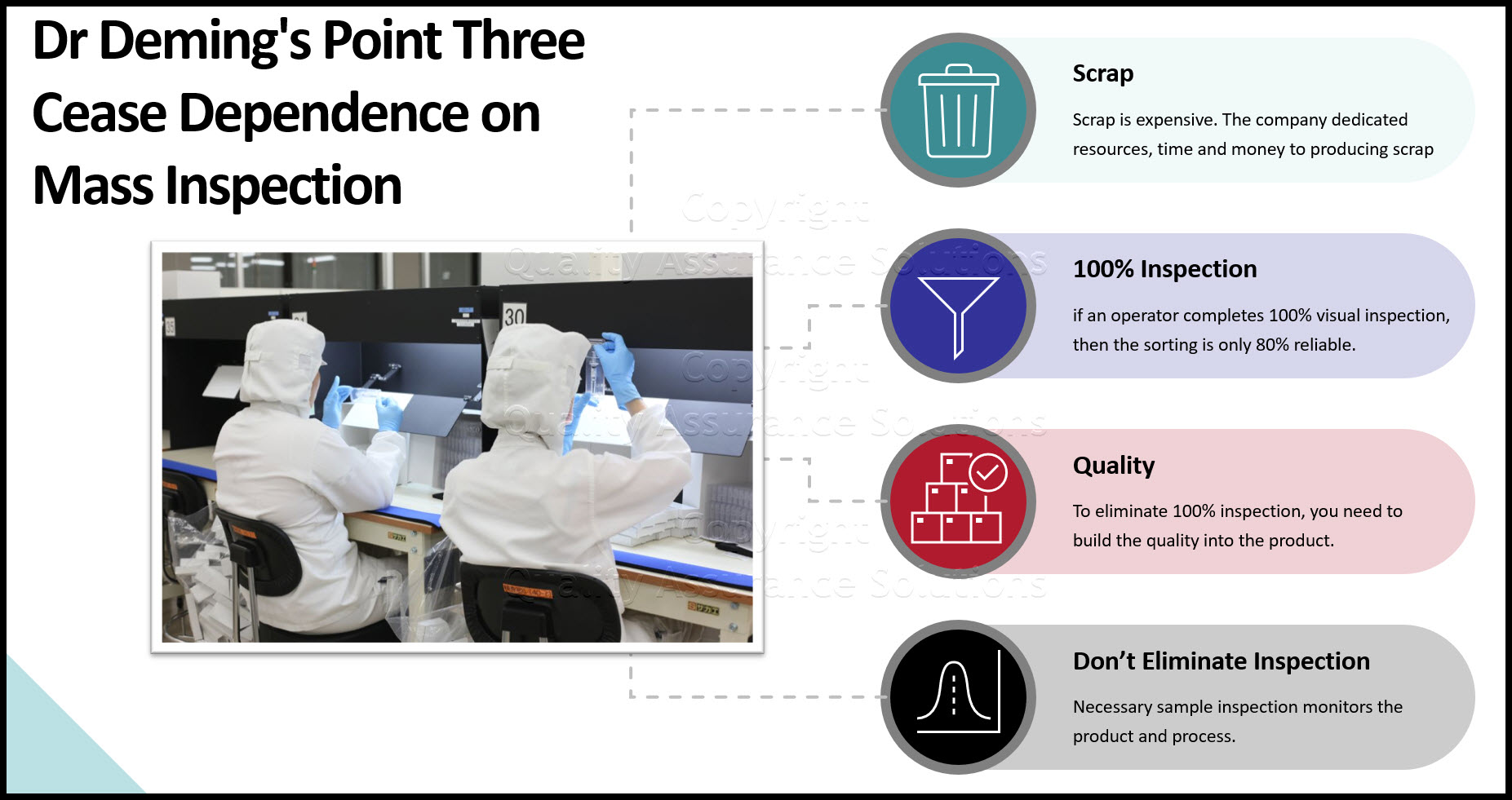

In a TQM environment, you sweat the details. You document the process details. You eliminate the waste or non value added steps. You assure that all employees follow the same process.

The processes produces product that satisfies the customer. The internal customer is the person receiving the product. If employees receive unsatisfactory product they are empowered to reject the product. Empowered employees can improve processes to minimize rejects.

Comprehensive ISO 9001:2015 Audit Checklist for Internal, Gap and Certification Audits.

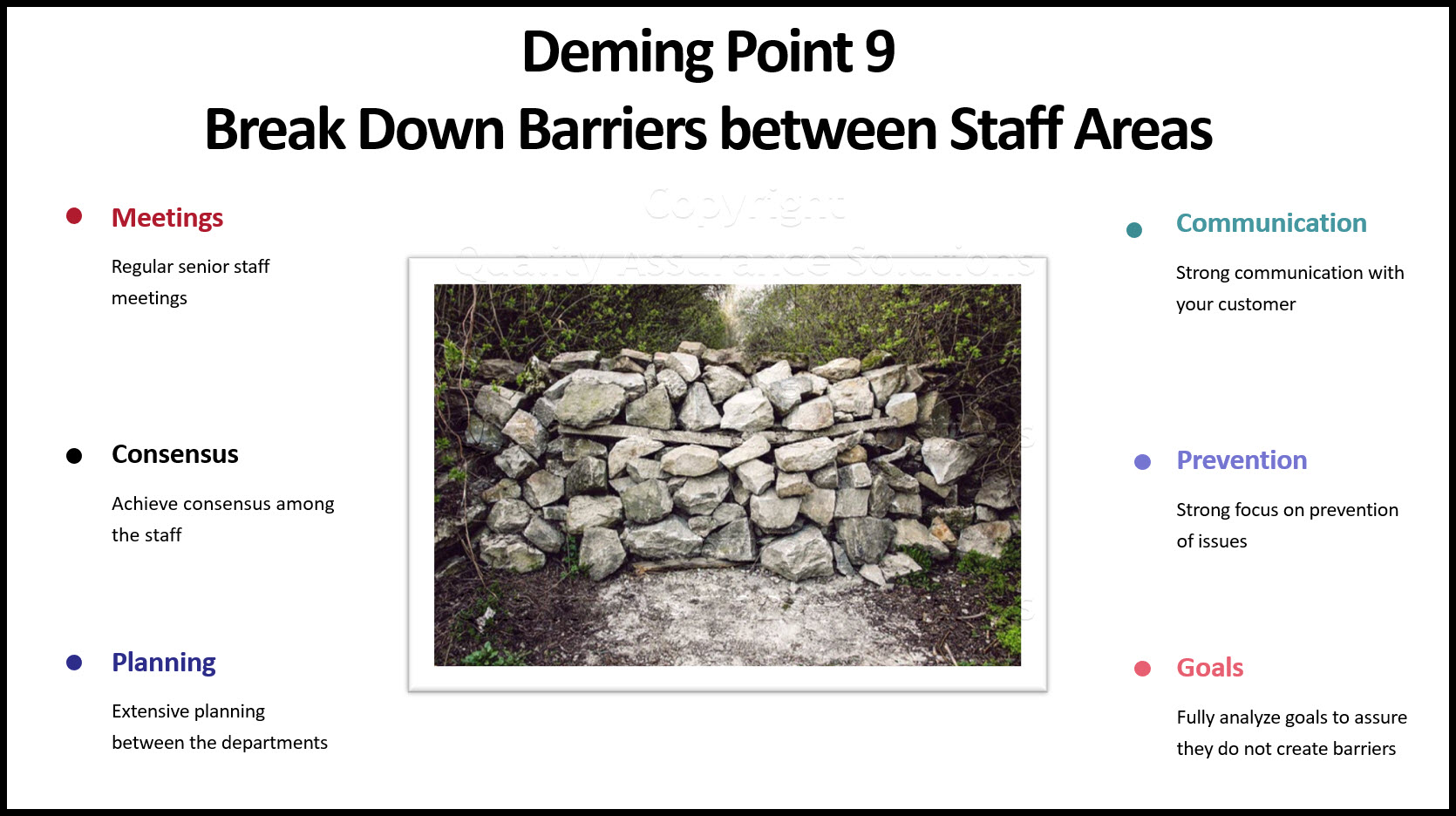

Improvement Teams

A TQM company will have a steering committee made from top management. The committee create projects, form project teams and monitor the teams improvement efforts. The projects will have significant and long term benefits to the company.

Improvement doesn’t happen by itself or from one person ideas. Every person contributes a unique and valuable point of view to the team. Train team members in the process improvement tools.

There are two types of teams:

1) Functional teams are from one area or department. They focus on issues that are internal to that area only.

2) Cross functional teams are created from members from multiple departments or areas. Empower members of cross functional teams make changes. They focus on processes, systems and problem projects.

I discuss more about teams here.

Your easy to edit ISO 9001:2015 Quality Assurance Manual.

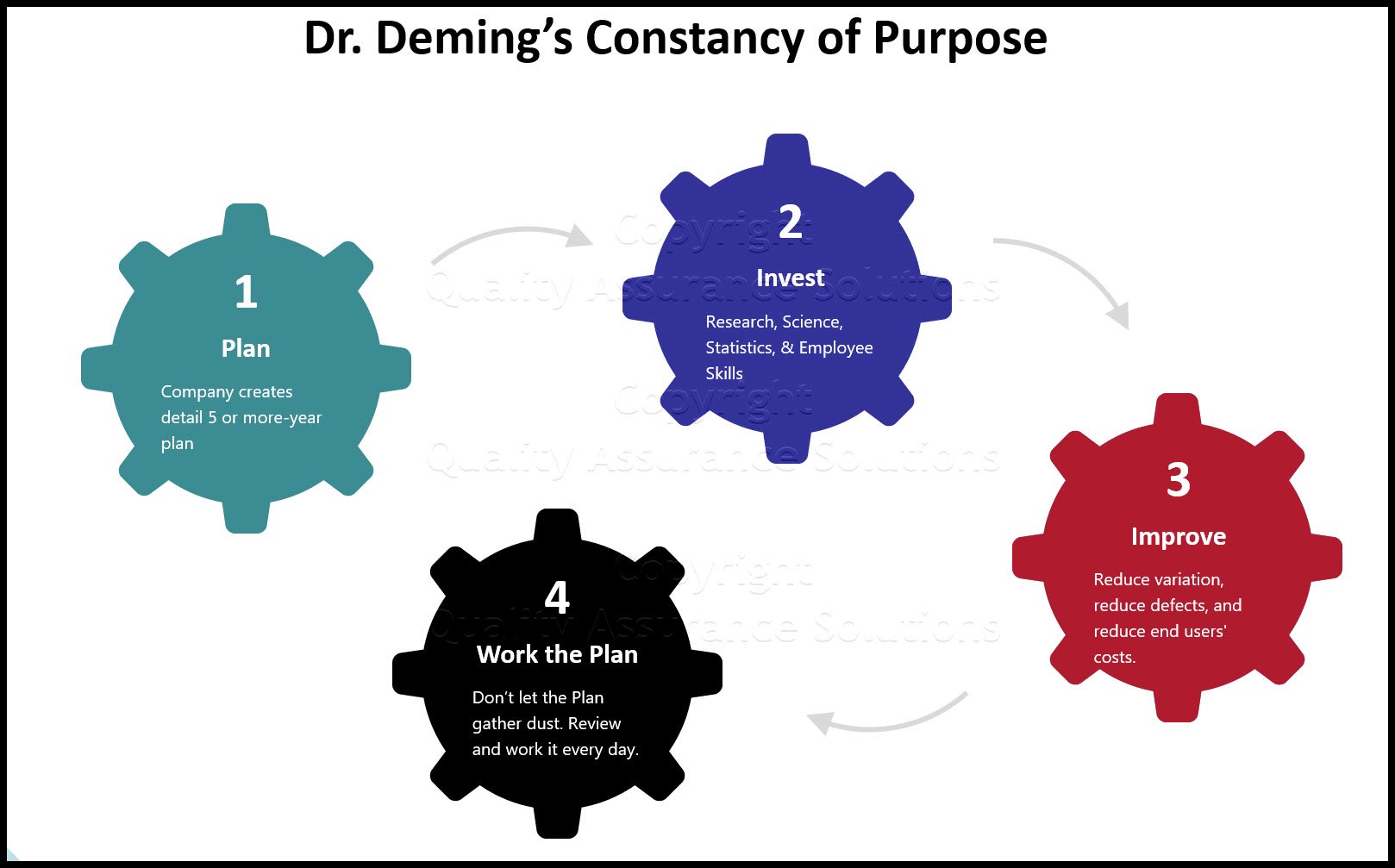

Long Term Thinking

TQM is a long term process. It can take up to 5 years to fully convert a company to TQM methodology. A company needs to have a 5 year vision to implement TQM. Every year the mission statement is reviewed and revised to strengthen the 5 year vision. Revision of the mission occurs because customer needs changes from year to year. However the overarching TQM vision remains the same.

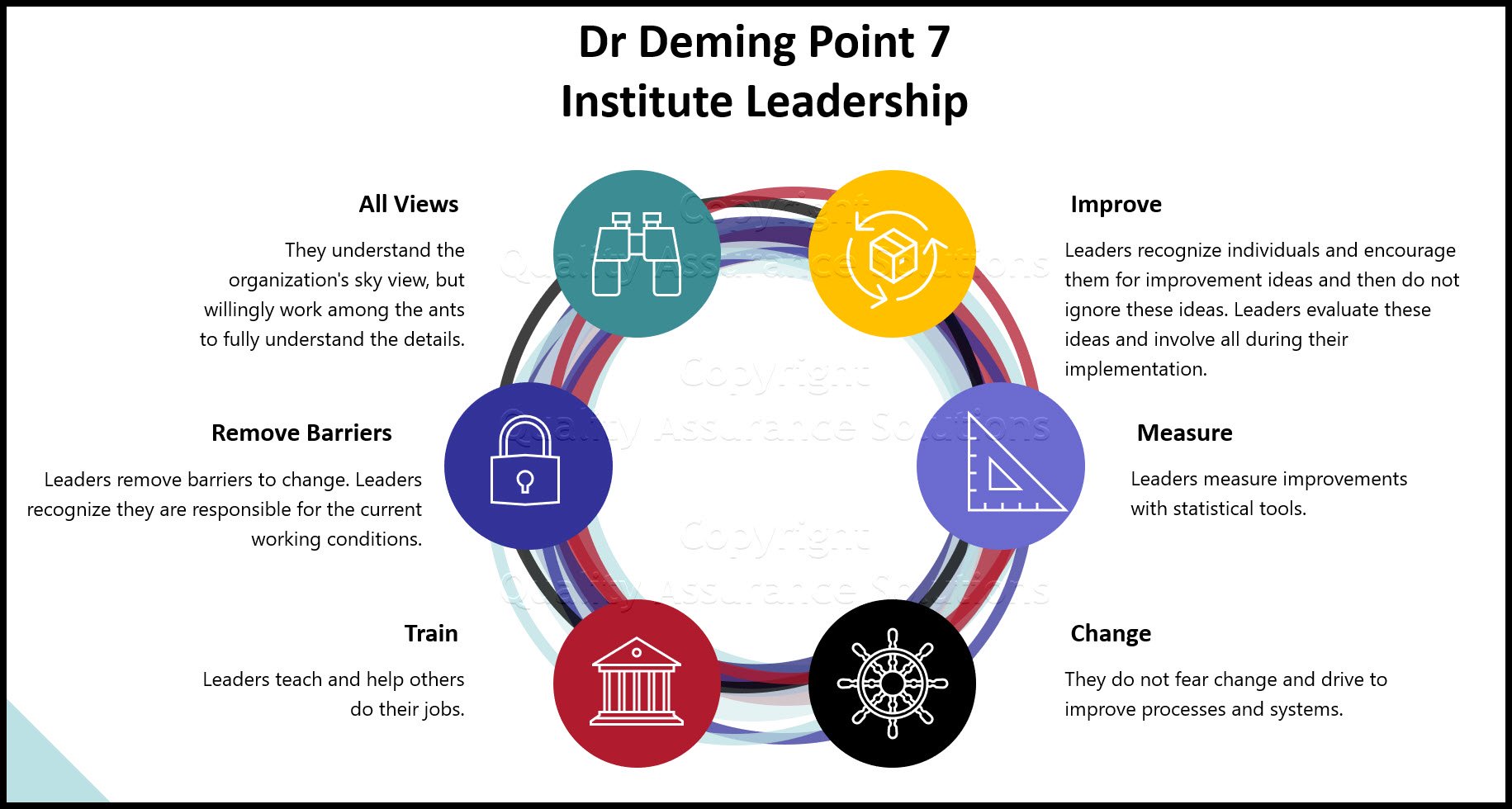

Management and Monitoring

TQM requires monitoring and management is responsible. Management monitors the improvement activities, the status of TQM and the processes.

When things go awry, management accepts the blame. Management does not blame individuals. They realize that their systems caused the issues. They understand that the systems can be fixed to correct the issues.

Management evaluates the effectiveness and efficiency of the TQM efforts. They measure the momentum of the cultural change. All management ensures are employees are trained and involved in TQM activities. Management uses software such as TrainingKeeper to evaluate the effectiveness and efficiency of training.

Get certified in Risk Management through our completely on-line training system. Study at your own pace.

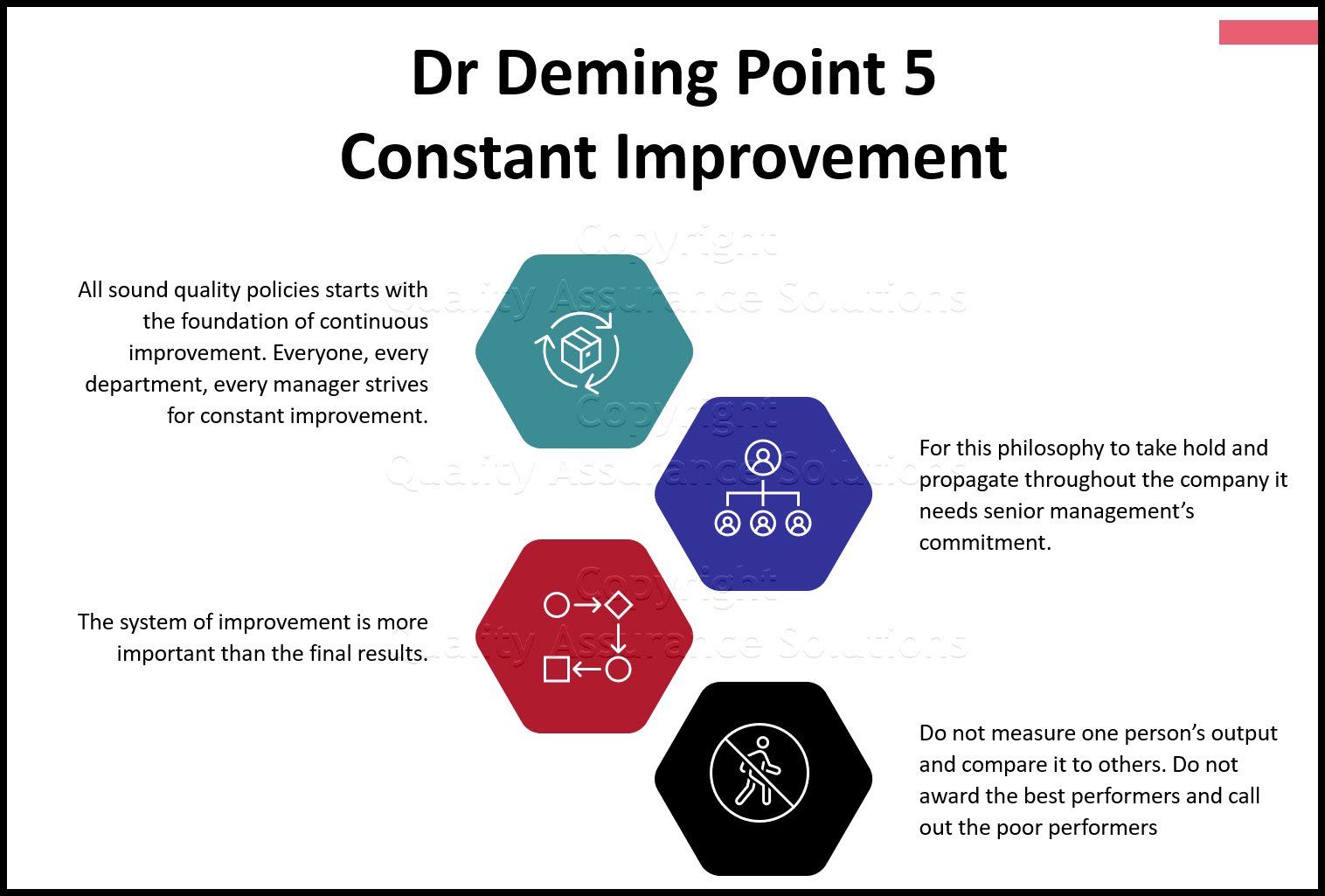

Continual Improvement

See here for Continual Improvement discussion.

Frequent Auditing

Auditing ensures that all employees are following documented processes. Auditing is used to improve the processes. Auditing is not used to denounce employees. See here for more on auditing.

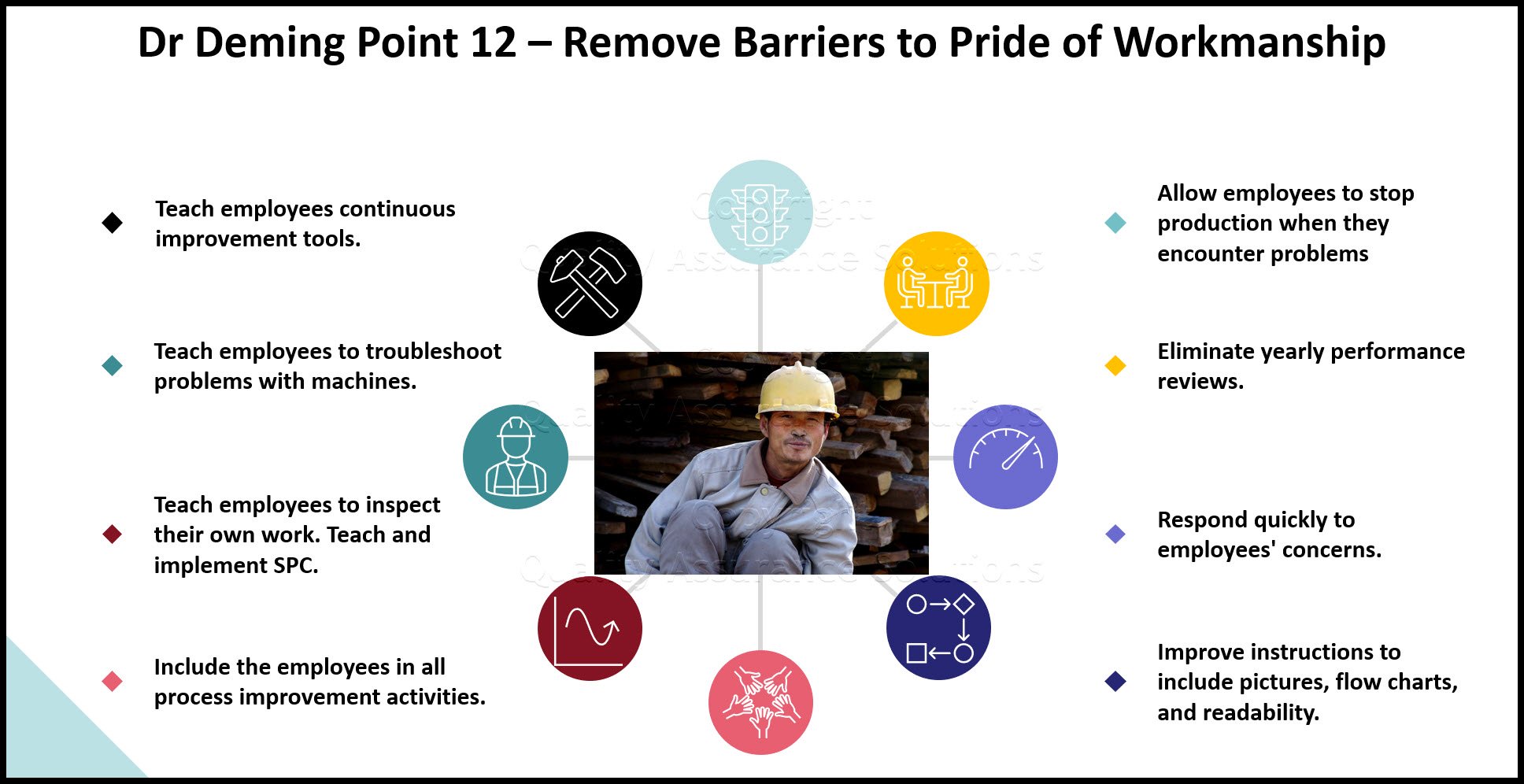

Employee Empowerment

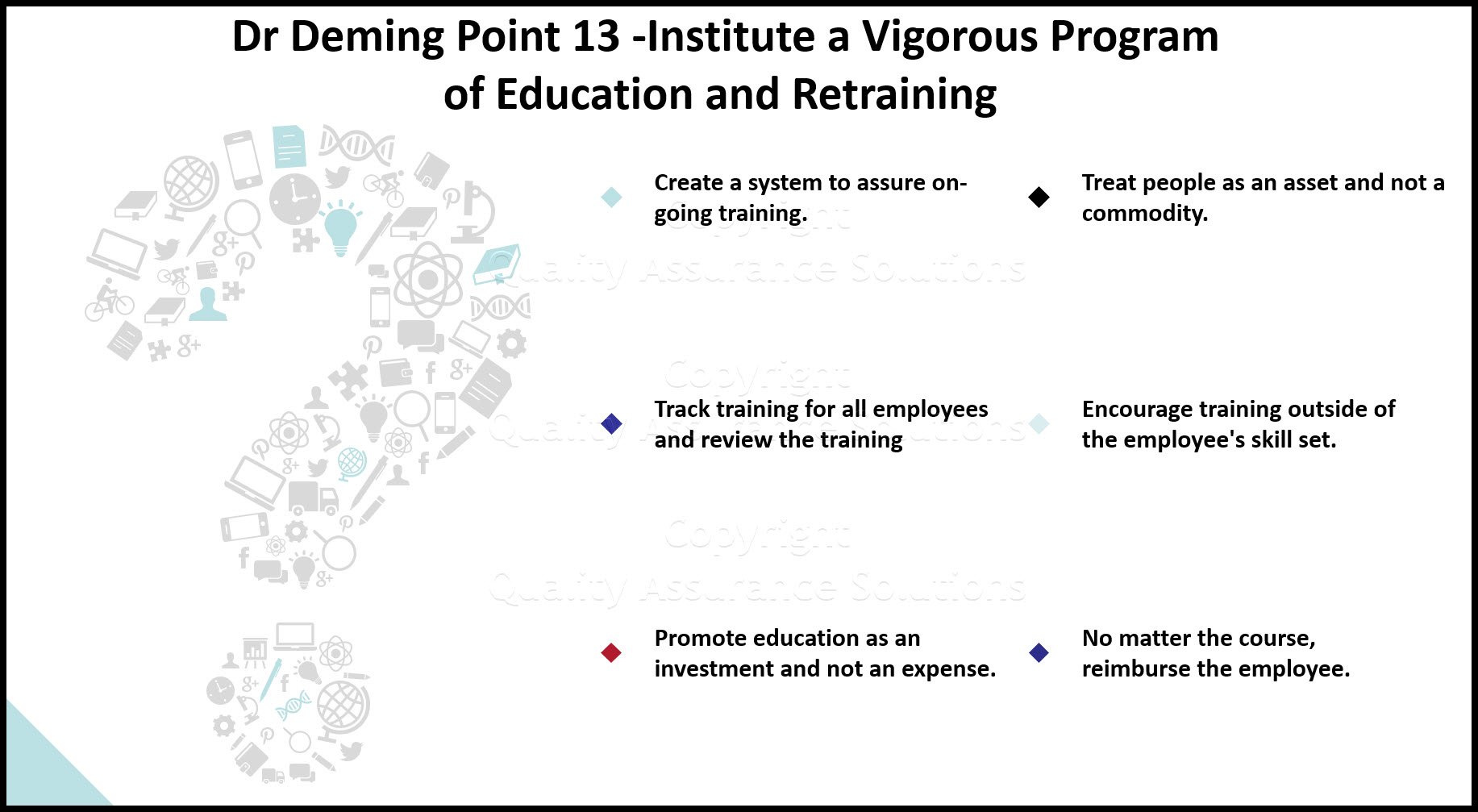

In the TQM methodology, employee empowerment becomes one of the most difficult hurdles. The difficultly comes from not providing effective training.

In order to empower employees, they need thorough knowledge to make quick and sound decisions. An empowered employee greatly benefits the company. You train and retrain your employees in product knowledge, TQM tools and your company’s systems.

An empowered employee always feels part of the team. They realize their contributions affects customer satisfaction.

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

Measuring and Controlling

Most of the TQM tools focus on measuring and controlling processes. Correct application of these tools greatly benefit your company. Controlled processes assures your customers receive the same outstanding product or service every time!

To improve you must be able to measure the improvement. Selecting the correct measurement tools is essential to TQM. A TQM company trains all employees in the TQM tools. With this knowledge empowered employees select the correct measuring tool. By applying the tools, you achieve customer satisfaction.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |