The Analysis Tollgates

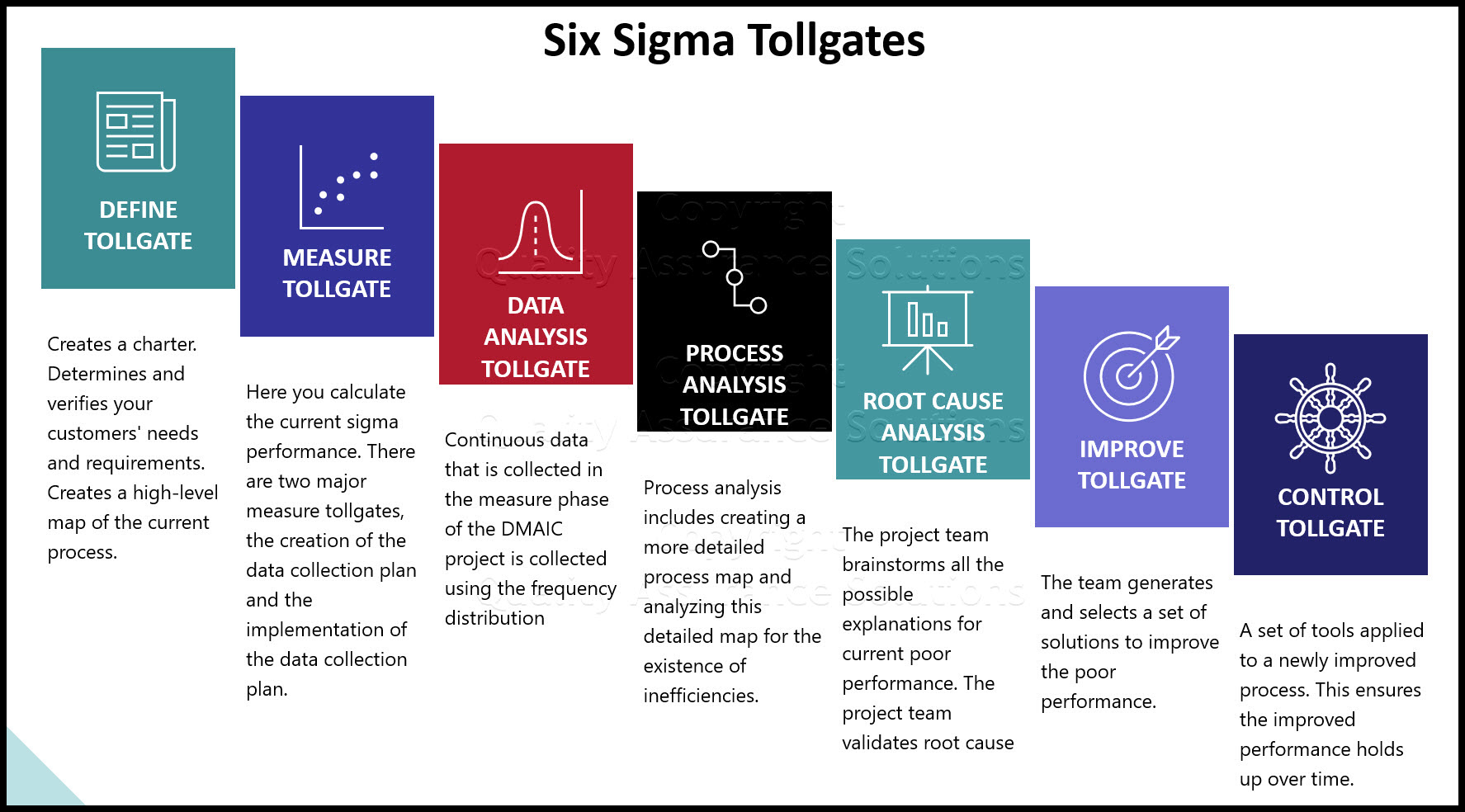

The third step in applying Six Sigma DMAIC is setting Analysis Tollgates. During this step, the team analyzes the collected data and the process itself. This leads to determining the root causes of the poor process performance.

There are three analysis steps in Six Sigma: Data Analysis, process Analysis, and Root Cause Analysis.

1. Data Analysis Tollgates

When data collected in the measure phase of DMAIC is discrete in nature, the most common statistical tools we use are the Pareto chart and the Histogram.

Continuous data that is collected in the measure phase of the DMAIC project is collected using the frequency distribution check sheet. Another continuous data analysis tool is the run chart. A run chart tracks some value over time allowing us to see if there are any shifts or trends in the data.

2. Process Analysis Tollgates

Process analysis includes creating a more detailed process map and analyzing this detailed map for the existence of inefficiencies.

Process Analysis: Sub-process Mapping

For the purposes of process analysis, sub-process mapping refers to taking one or more high-level process step and drilling down to the five to seven steps below that high level. Often these steps will reveal inefficient, non-value-added steps. Later the team should attempt to change or even remove these steps.

Process Analysis: The Nature Of Work

Once the subprocess map has been created and validated by the project team, they need to analyze the map for non-value added steps. Each non-value added step can be categorized into one of the following types of non-value-added activities:

- Internal failure: Steps that must be done more than one time.

- External failure: Failures in the process detected by the customer.

- Delays: Waits in the process.

- Control/inspection: Steps in the process that verifies previous work has been done correctly.

- Preparation/set-up: Steps in the process that prepare for a following step which causes process delays.

- Moves: Steps that move a product or element in service from one place to another.

- Value enabling: A necessary non-value-added step in the process that would not be targeted for improvement because it is enables the functioning of the organization.

Micro Problem Statements: The Last Step in Data and Process Analysis

You phrase the microproblem statement in the form of a question that begins with the word -Why. The micro-problem statements allow the project team to specify the problem they are trying to impact. Microproblem statements come from either data analysis or process analysis.

Your on-line Lean Six Sigma Certification. Course includes videos, reference materials, mobile app, quizzes and a certification test. Start studying today and get certified at your own pace.

3. Root Cause Analysis

The third and most important analysis tollgate is root cause analysis.

The Three Steps to Root Cause Analysis

Project teams must complete three important steps for root cause analysis. They are:

1. The open step: during this phase of root cause analysis, the project team brainstorms all the possible explanations for current poor performance.

A simple formula to help the team through root causation is: Y = f(x). The Y in this formula refers to the problem associated with the micro-problem statement. The f(x) refers to process variables that could cause the problem stated in the micro-problem statement

2. The narrow step: during this phase, the project team narrows the list of possible explanations for the current poor performance.

3. The close step: during this phase, the project team validates or proves out the narrowed list of explanations. Testing the narrowed list of potential root causes can be done through scatter analysis

4-The Improve Tollgate

The fourth step of applying six sigma tactics is improving. In this step, the team generates and selects a set of solutions to improve the poor performance. There are two improve tollgates, generating solutions and selecting solutions. It is recommended that when implementing solutions, the project team prioritizes the solutions and implements them one at a time or in group. After each implementation the team recalculates process performance. This should be done until the team meets the objective. The project team may meet the goals and objectives without implementing all the proposed solutions.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |