|

|

|

|

Six SigmaGreen Belt Training |

Overview

This Six Sigma Green Belt training course provides you with an understanding of the various Six Sigma tools and techniques useful to improve the production process and minimize defects in the end product. This certification focuses on the practical implementation of these tools and techniques in the organization.

Certification Exam Format

Audience Profile

We highly recommend this Green Built training course for employees and organizations requiring a standardized approach to problem solving for continuous improvement in Quality Management.

Prerequisites

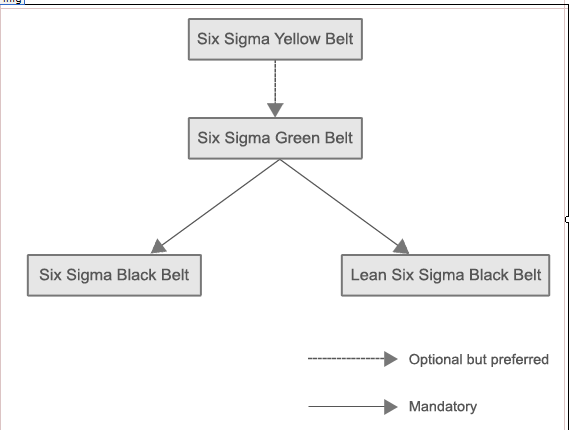

Preferably Six Sigma Yellow Belt (But Not Mandatory). You can take this course free through the link. Plus, this lets you preview our excellent training material.

|

After purchase, we will enroll you in the course. This may take up to 24 hours, but most likely much quicker. Satisfaction Guaranteed.

|

Add to Cart |

Six Sigma is a data driven, customer focused, and result oriented methodology which uses statistical tools and techniques to systematically eliminate the defects and inefficiencies to improve processes. This systematic method measures and analyzes the business processes to identify the critical factors that affect business results. Six Sigma green belt training improves the processes and establishes necessary controls around the improved processes.

Six sigma is a widely accepted quality concept in the corporate world today. Six Sigma started its journey in the 1980s as a data-driven method to reduce variation in electronic manufacturing processes in Motorola Inc. in the USA. Six Sigma became famous when Jack Welch made it vital to his successful business strategy at General Electric in 1995. Today, companies use it as a business performance improvement methodology all over the world in diverse industry, including general manufacturing, construction, banking and finance, healthcare, education, government, KPO/BPO, IT/ Software. At present, IT/ ITES sector companies dynamically implement Six Sigma and no longer confined to the manufacturing sector.

The term ‘six sigma’ comes from statistics used in statistical quality control (SQC) which evaluates process capability. Process capability measures the ability of a process to meet the customer's specifications. It originated from terminology associated with manufacturing, which refers to the ability of a manufacturing process to produce a very high proportion of output within specifications.

The sigma rating of a process indicates its yield or percentage of defect-free outputs it produces. A six sigma process is the one which produces 99.99966% statistically defect-free outputs, which equals 3.4 defects per million opportunities (DPMO).

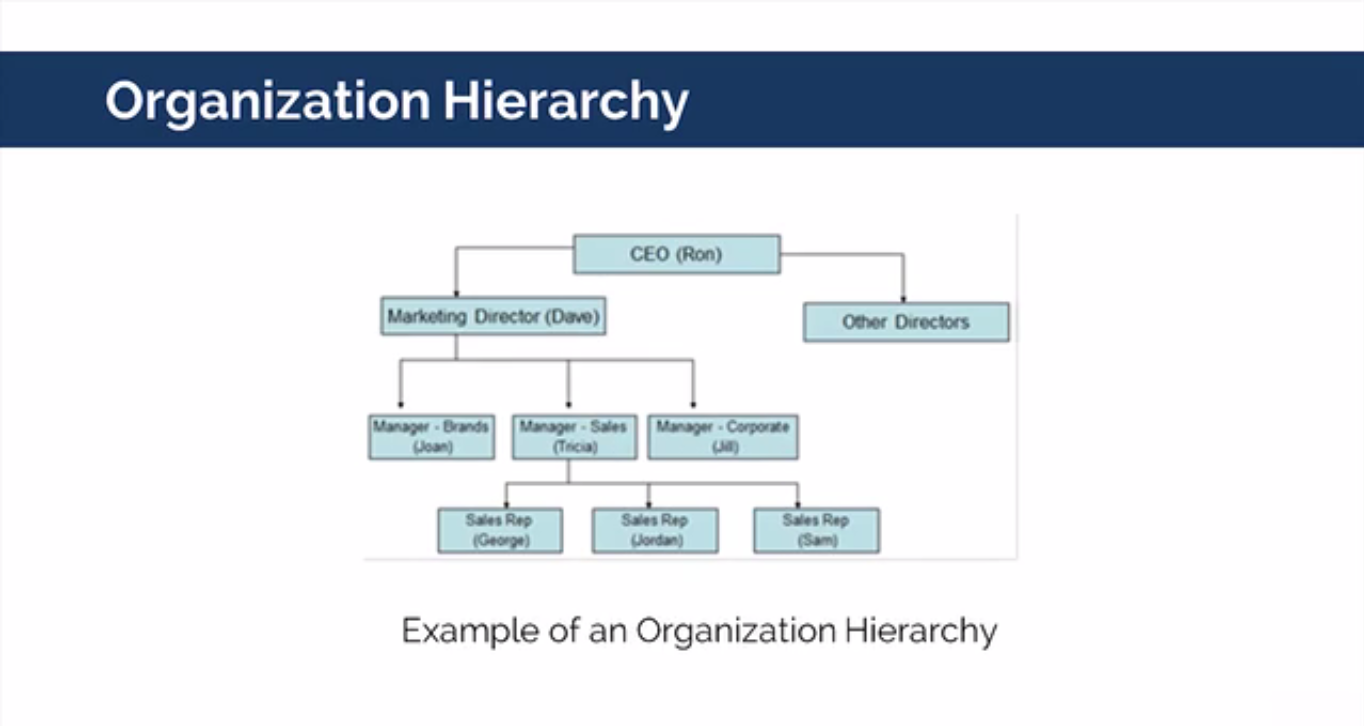

Six sigma green belt training uses a set of quality management and statistical methods and creates a team of experts within the organization (Executive Leadership, Champions, Black belt, Green Belt, Yellow Belt, etc.) having specific skill sets required to carry out the six sigma project. Each six sigma project carried out within an organization follows a defined sequence of phases with quantifiable value targets. Target examples include reduction in process cycle time, reduce cost, increase in quality rating/ customer satisfaction index, and reduction in defect rate.

Our widely accepted certifications help individuals and organizations complete projects with greater efficiency, increase ROI and customer satisfaction.

Many organizations around the globe adopted Six Sigma and Lean to increase quality of the outputs and to reduce cost by means of reducing defects and removing inefficiencies. There are numerous benefits of adopting Six Sigma.

For Individuals

The growing popularity and acceptability of Six Sigma green belt training created a great demand for certified professionals in the job market. Grab the opportunity and join this growing community. Six Sigma certification yields higher wages.

For Organizations

Six Sigma and Lean certified professionals help organizations with an improved level of project management that leads to increased ROI. They have knowledge pertaining to and can anticipate issues related to the practical implementation of Six Sigma.

Six Sigma Certification Hierarchy

| Six Sigma | Traditional Quality |

|---|---|

| Decisions are driven by data | Decisions are taken based on a combination of data and 'gut feel'. |

| Control process inputs (Focus on X’s) | Inspection method (Focus on Y) |

| Structured use of statistical tools to help in problem solving | No formal structure exists for the application of tools |

| Structured training in applied statistics | Lack of structured training |

| Root cause approach | Band aid approach |

| Prevention over inspection | Inspection over prevention |

There are mainly two methodologies of Six Sigma Green Belt training namely DMAIC and DMADV.

DMAIC stands for data-driven Six Sigma methodology that improves existing products and processes. Use the DMAIC process to make an existing product or process meet or exceed the customer’s requirements. DMAIC methodology consists of five phases...

DMADV is a common DFSS (Design for Six Sigma) methodology used to develop a process or product which does not exist in the company. DFSS focuses on the design or redesigns of the different processes used in product manufacturing or service delivery by considering the customer needs and expectations. Use DMADV when the existing product or process does not meet the level of customer specification or Six Sigma level even after optimization with or without using DMAIC. DMADV methodology consists of five phases...

Certificate and 25+ PMI Approved PDUs

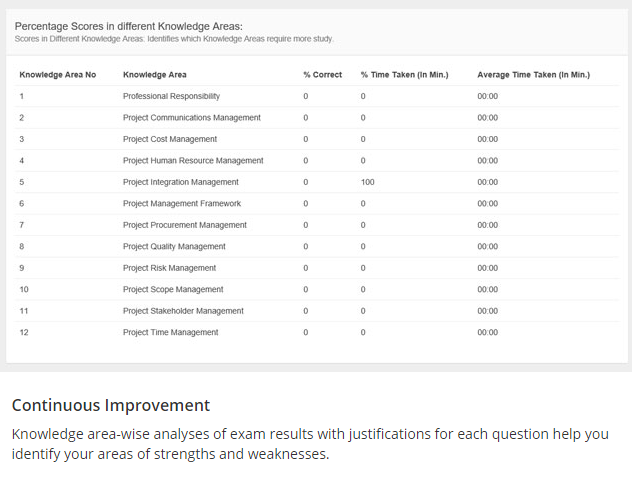

Continuous Improvement Feedback

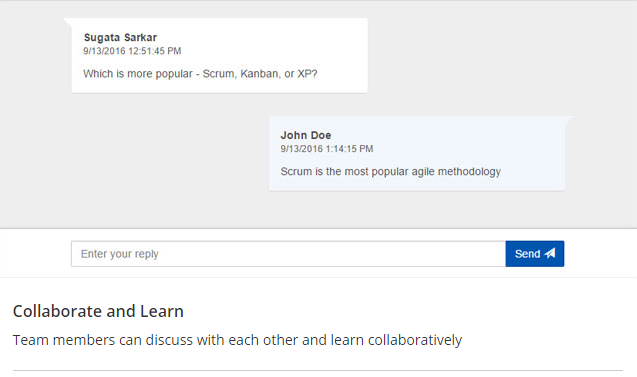

Collaboration Tools

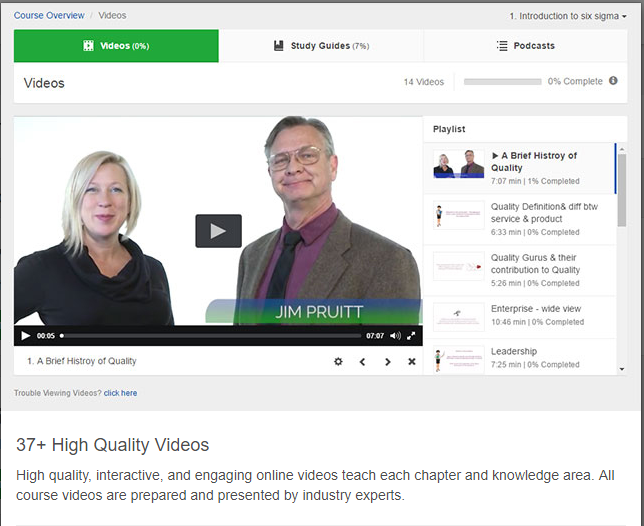

37 High Quality Videos

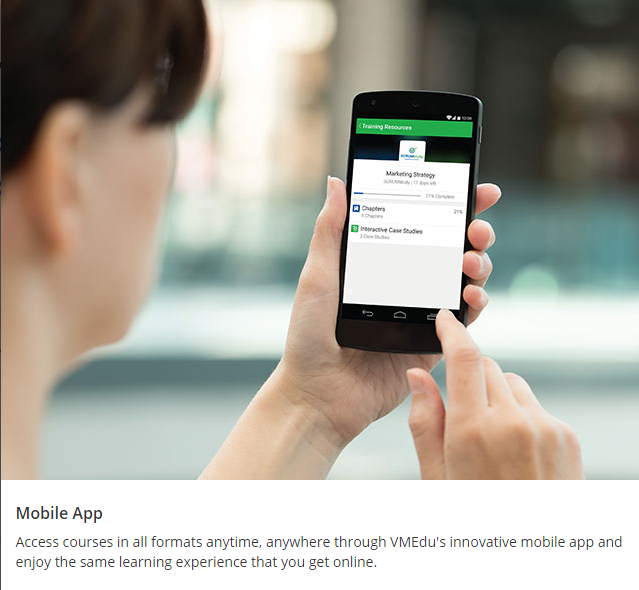

Mobile App

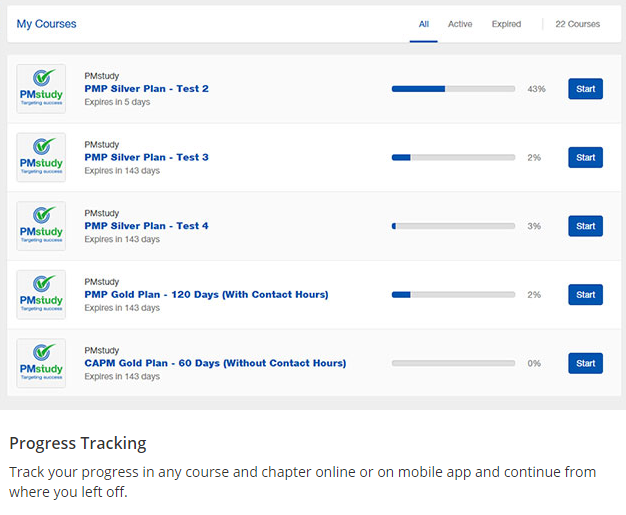

Progress Tracking

8 Six Sigma Green Belt Training Study Guides