Attribute Sampling Plans

Use attribute sampling tables to determine whether or not to accept a lot. After you gather your sample, you then inspect the parts for a given feature. During the inspection you sort the parts between acceptable and defective. Depending on the number defective you then decide if you accept or reject the lot.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Attribute Sampling vs Variable Sampling vs 100%

If you have the choice between attribute, variable, and 100% inspection, which one should you use?

100% inspection is the most expensive type of sampling because every part is inspected. All parts are sorted between good and bad. Use 100% inspection for critical features with a low CpK number.

Variable inspection is useful for process control and CpK determination. Variable inspection can be used to calculate lot quality. It is more expensive then attribute sampling because you need to record the actual data, calculate the statistics and graph the data.

Attribute sampling tables bears the lowest sample size which makes it the most economical. It is the easiest to setup and track. Because of the lower sample size you handle the product less. If you conduct destructive testing, it makes sense to use this type of sampling plan because you destroy fewer parts. This sampling saves documentation time, because you only need to record the number inspected, the number accepted and the number of defects but do not need to record the actual values.

Common Terms

- N = Lot size

- n = Sample Size

- AQL = Acceptable Quality Level. This is the percentage of parts that you reject on. If the AQL is .1 then you inspect to assure .9 (90%) of the parts are good. AQL represents the limit of satisfactory process average. It is the poorest level of quality for the vendor's process that the consumer would consider acceptable as a process average.

- Acc / Rej criteria. The first number is the number of defective parts allowed. The second number represents the number of defective parts that makes you reject the lot. For example; Acc / Rej is 0 / 1 then 0 defects are allowed within the sample. If you find 1 or more defects in the sample then you reject the lot. Another example; Acc / Rej value is 2 / 3. If you find 2 or less defective parts then you accept the lot. If you find 3 or more defective parts then you reject the lot.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Requirements for Attribute Sampling

With attribute sampling you start with a lot or batch of material. Parts in the lot must come from the same area, same time period, same processes etc. Prior to applying a sampling plan be sure to define your lot properties.

Use random sampling. Random sampling means you did not prepare your selection of parts. If possible, employ a computer random generator for the selection of parts. If you select a non-random sample then you introduce bias into your results.

To determine the sample size and accept / reject levels you need to know these items

- Type of sampling plan

- Size of Lot

- Acceptable Quality Level. (AQL)

- The inspection feature and critical level

- Application, is it for receiving inspection, in-process or final inspection?

- Defect history

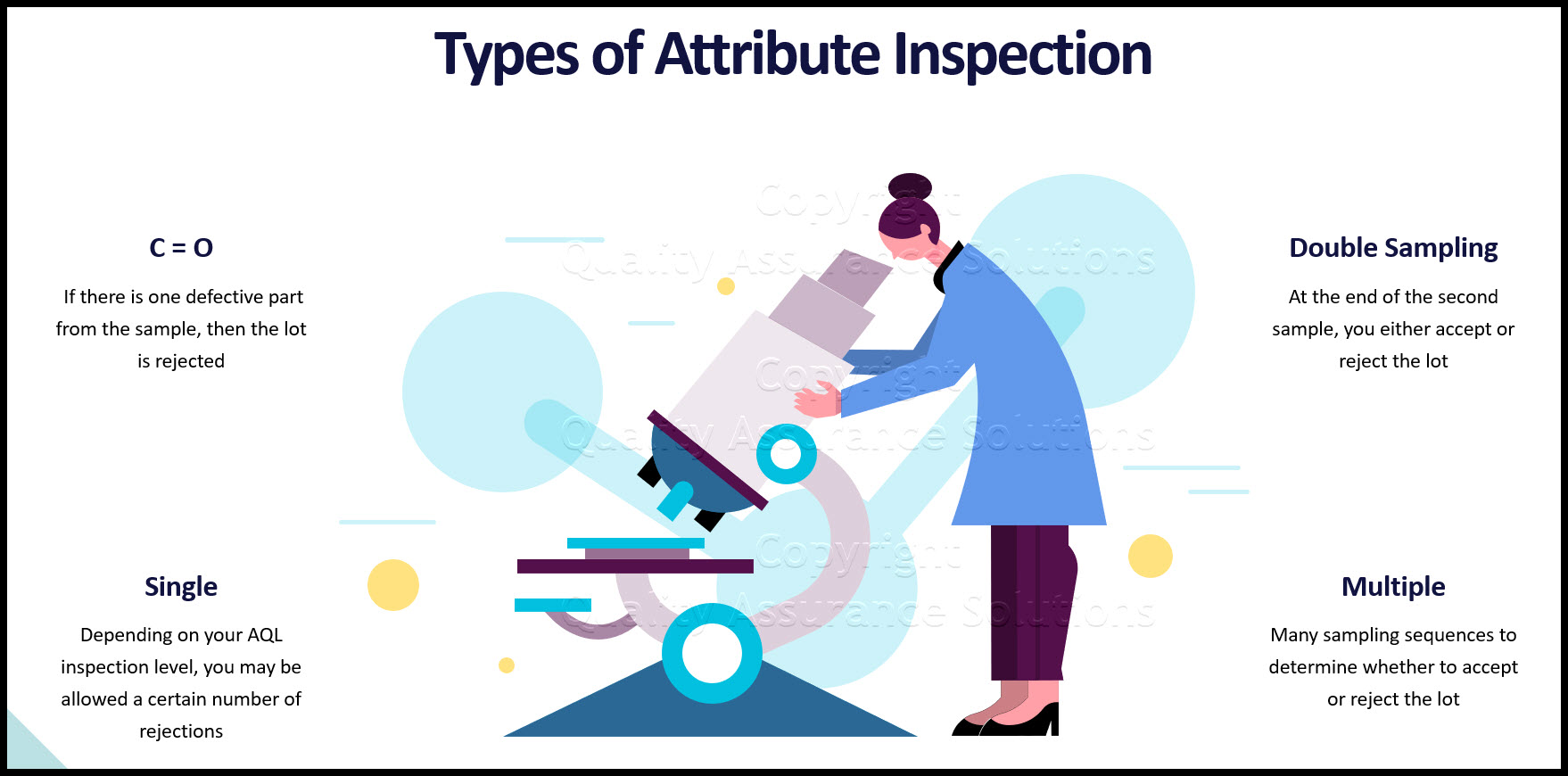

Types of Attribute Sampling

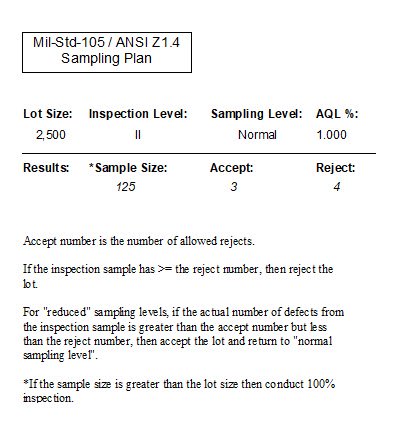

C = 0 / Zero Acceptance. C stands for the allowed number of rejected parts. If there is one defective part from the sample then the lot is rejected. Zero acceptance sampling plan has the lowest sample size of the plans yet it has the highest risk of conducting errors. A C = 0 plan is a type of single sample plan (discussed below).

Single sample plan. You accept or reject the lot on one sample only. Most sampling plans such as Mil Std 105, ANSI Z1.4 or Dodge Romig plans incorporate a single sample plan. In many cases, depending on your AQL inspection level, you may be allowed a certain number of rejections.

For example the table may tell you to accept on two and reject on three. If you find 3 or more defects within your sample then you reject the lot for your inspection feature. If you find 2 or less defects then you accept the lot. You document this as ACC/REJ = 2/3.

Double-sampling These plans combine single sample plans. With double sampling plans you end with three different conclusions.

- Accept the lot

- Reject the lot

- Resample the lot

If you resample the lot the results are combine with the first sample. A new Acc / Rej level number is determined with the second sampling. At the end of the second sample you then either accept or reject the lot.

Multiple sampling plans These are the most complicated. Similar to double sampling, there may be many sampling sequences to determine whether to accept or reject the lot. Although complicated, initially, they may utilize smaller sample sizes to accept the lot. However, if there are rejects then multiple sampling plans become a nightmare.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Attribute Sampling Cautions

Be warn of these cautions when applying this type of inspection. These plans do not control quality. They do not prevent quality issues and only alert you after the problem. You cannot use this inspection method to improve the product quality. Utilize these sampling plans for lot acceptance / rejection only.

When parts fail the inspection then conduct 100% inspection on the lot. After the inspection, repeat the sampling according to your selected attribute plan.

If parts fail the inspection, do not repeat the inspection hoping for improvement. Usually this is a waste of time.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |