SPC Calculations

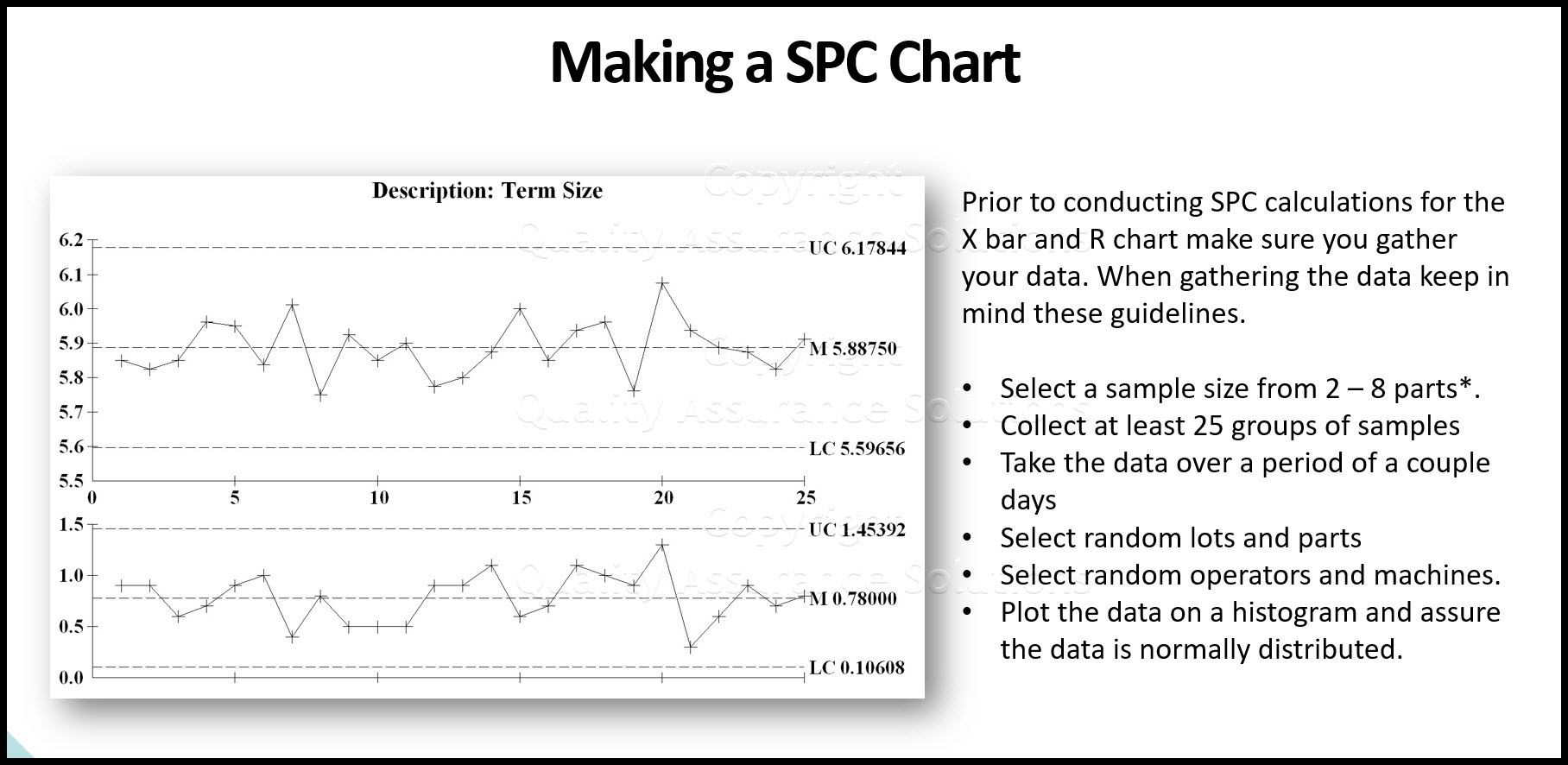

Prior to conducting SPC calculations for the X bar and R chart make sure you gather your data. When gathering the data keep in mind these guidelines.

- Select a sample size from 2 – 8 parts*.

- Collect at least 25 groups of samples

- Take the data over a period of a couple days

- Select random lots and parts

- Select random operators and machines.

- Plot the data on a histogram and assure the data is normally distributed.

* Do not change the sample size after you start collecting your data and plotting the points.

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

Limit SPC Calculations

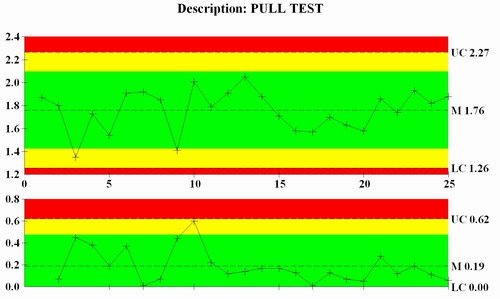

1) For each group of samples calculate the mean and the range.

2) Calculate the overall mean which is know as

3) Calculate the mean of all of the ranges. This is known as

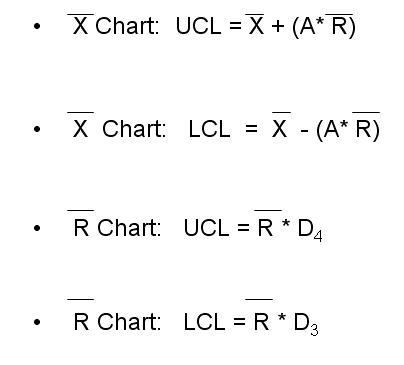

4) Now you are ready to calculate the limits. See below for the equations

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

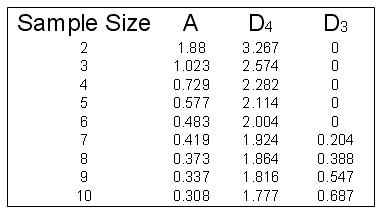

Here is the table for the constants. The constants depend on your sample size.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |