TRIZ Inventive Principles

25 through 32

Click below to read

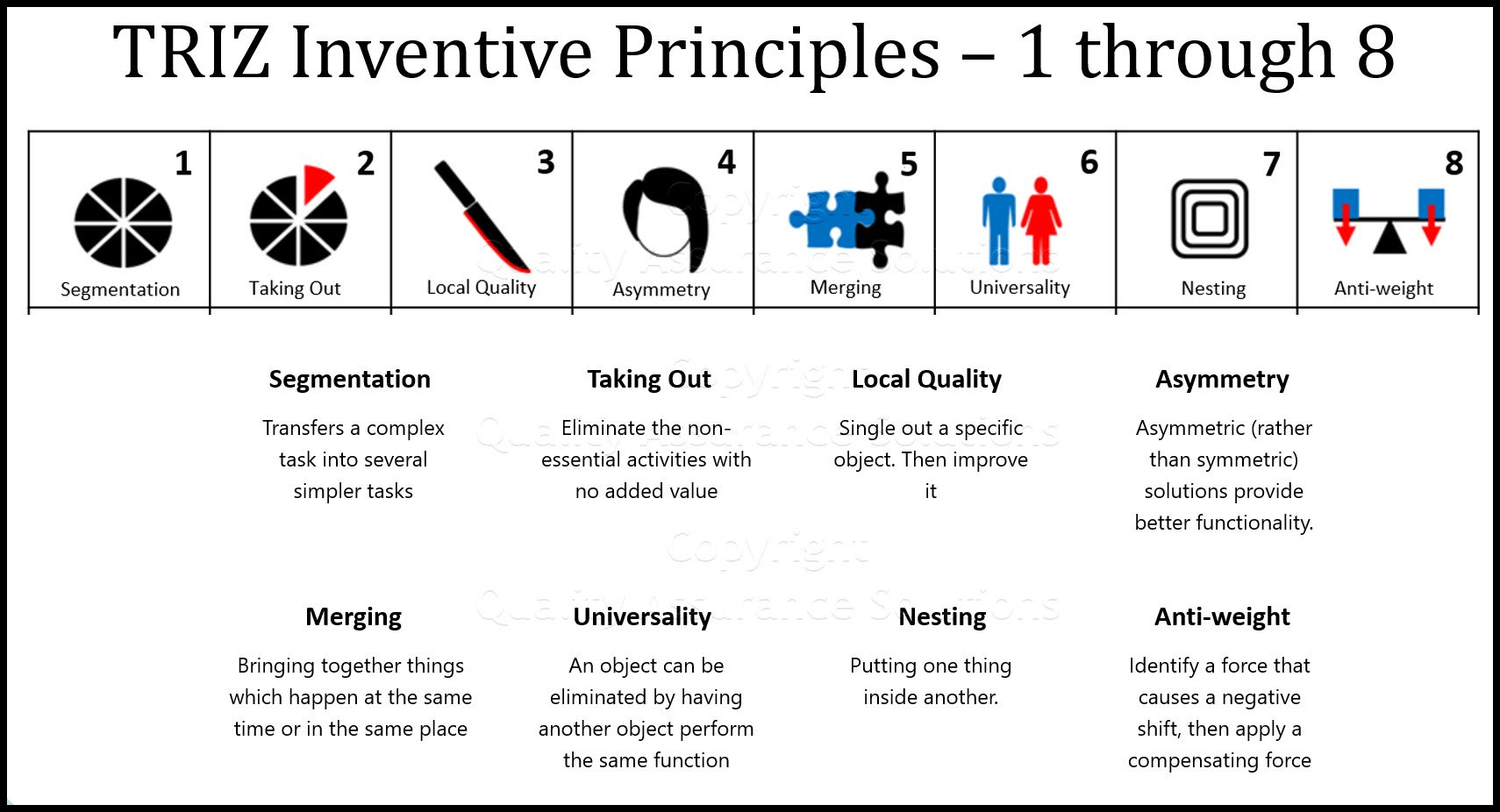

TRIZ Inventive Principles 1 - 8

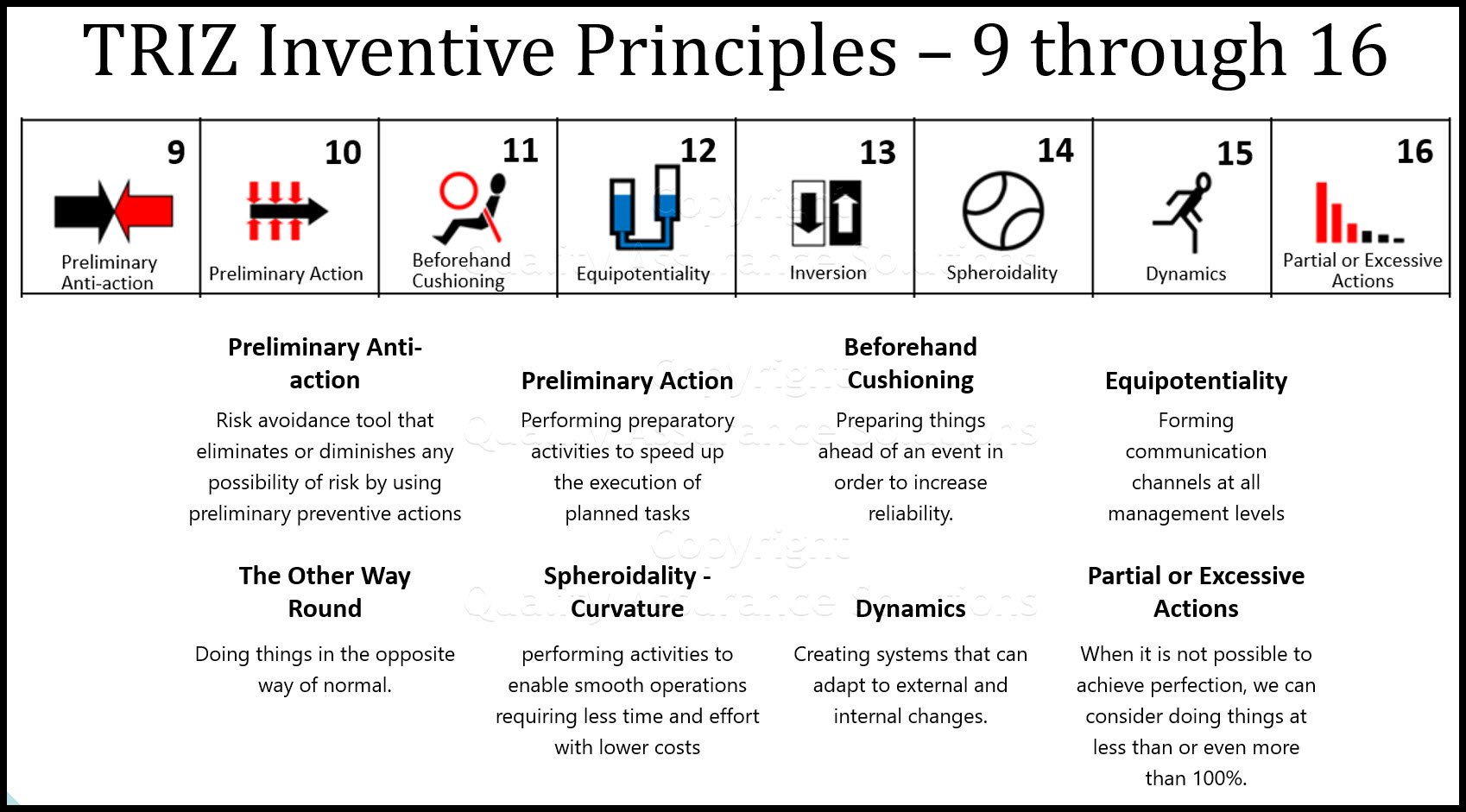

TRIZ Inventive Principles 9 - 16

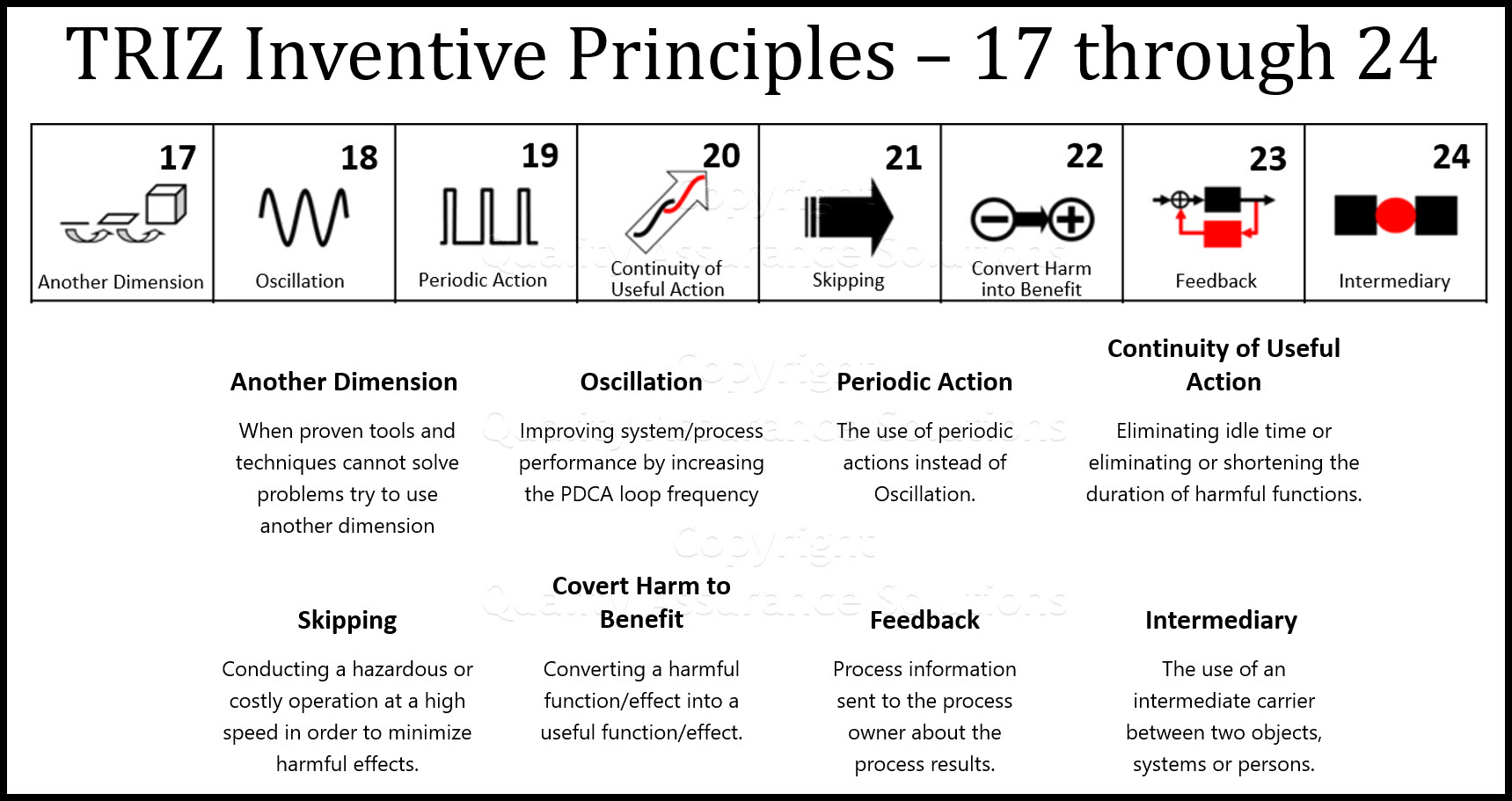

TRIZ Inventive Principles 17 -24

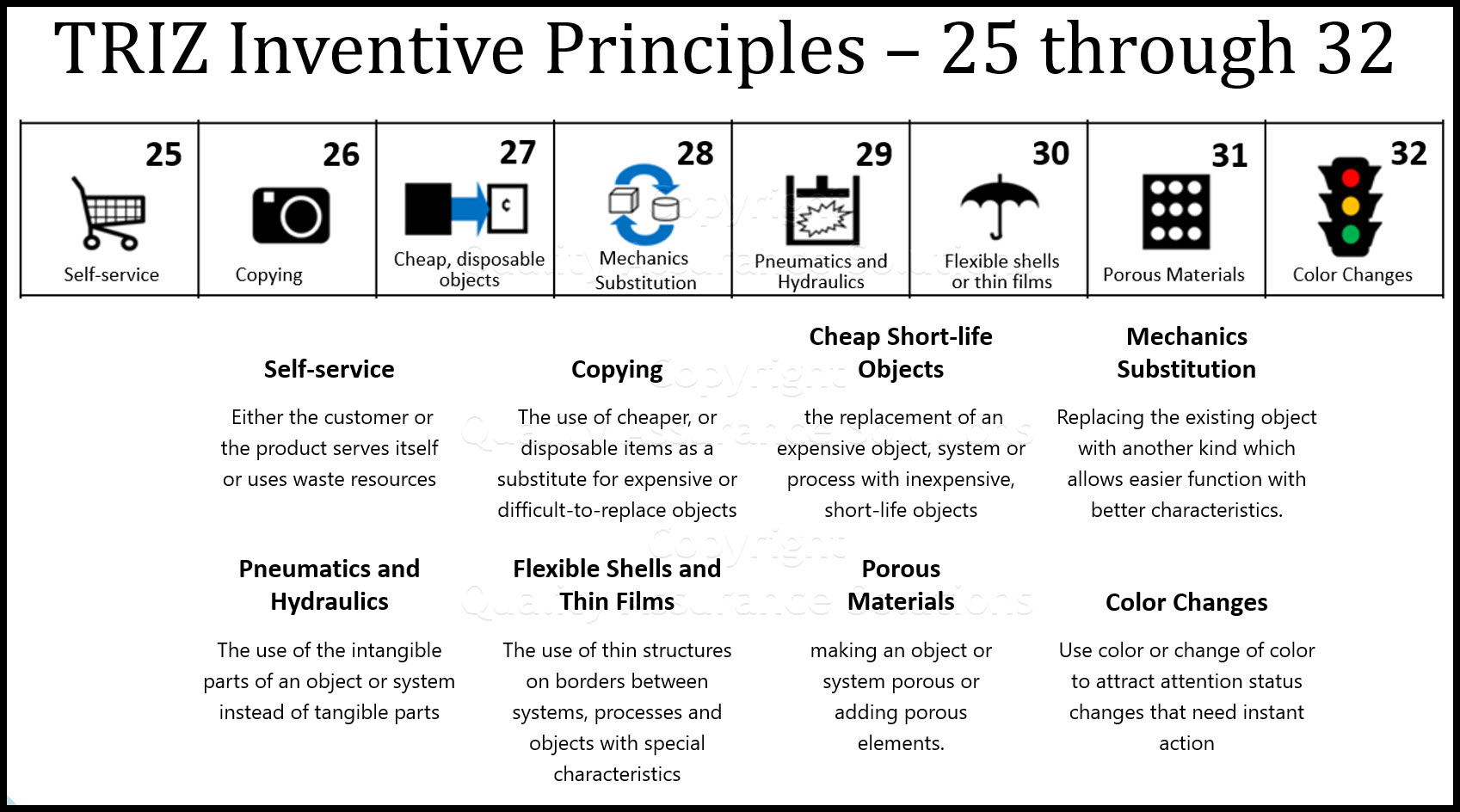

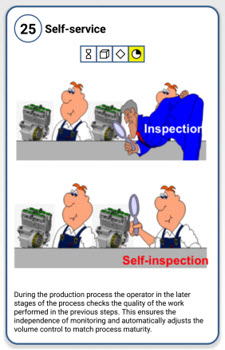

25. Self-service

The inventive principle ‘Self-service’ implies that either the customer or the product serves itself or uses waste resources.

Examples:

- Switching from an independent inspector to the one who produces the material as the inspector. This approach builds quality into the product rather than attempts to inspect the quality of the product itself. The program reinforces the personal responsibility for tasks. As a result, inspection personnel have become assessors of the process and product while acting as coaches for the operators.

- Another Self Service method, centering around utilizing waste resources, includes selecting scrap parts as visual examples for defective issues.

26. Copying

The inventive principle ‘Copying” implies the use of cheaper, disposable and inexpensive copies as a substitute for expensive, fragile or difficult-to-replace objects. It may involve replacing an object or process with optical copies.

Examples:

- Instead of an unavailable, expensive, fragile object, use inexpensive copies (i.e. listening to a CD instead of attending a concert).

- Replace an object or process with optical copies (i.e. videoconference).

- If visible optical copies are already used, move to infrared or ultraviolet copies (i.e. infrared images to detect heat sources).

Your comprehensive package for learning and training the TRIZ problem solving methodology. Includes mobile app, books, PowerPoints and real world examples.

27. Cheap Short-life Objects

The inventive principle ‘Cheap, Short-life Objects’ implies the replacement of an expensive object, system or process with inexpensive, short-life objects, systems or processes while compromising certain qualities such as durability and maintainability.

Examples:

- Use disposable tools when disposable tool can be cheaper than the cost of cleaning, sharpening or maintaining the tool (i.e. medical surgery instruments).

- Use CAD and CAM tools to design and evaluate the designs and use computers to assist in all the operations of a manufacturing process.

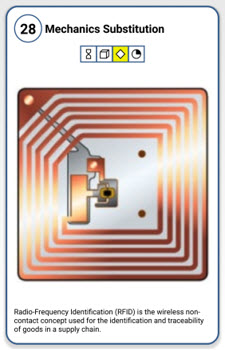

28. Mechanics Substitution

The inventive principle ‘Mechanics Substitution’ means replacing the existing concept, system, process or object with another kind which allows easier implementation of the required function with better characteristics.

For Example...

The NFC (Near Field Communication) can be used for information transfer from the RFID tag to a mobile phone.

Your comprehensive package for learning and training the TRIZ problem solving methodology. Includes mobile app, books, PowerPoints and real world examples.

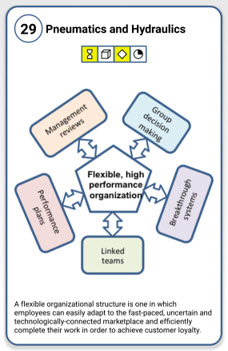

29. Pneumatics and Hydraulics

The inventive principle ‘Pneumatics and Hydraulics’ refers to the use of the intangible parts of an object or system instead of tangible parts.

Example...

The flexibility of an organization with regards to the interface between an organization and its target customers. Front office personnel should be competent for communicating with customers and quickly problem-solving. One can use the Kano diagram for determining customer excitement requirements.

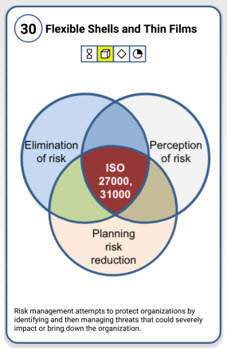

30. Flexible Shells and Thin Films

The inventive principle ‘Thin Films’ refers to the use of thin structures on borders between systems, processes and objects with special characteristics such as low cost, low space, low weight and high flexibility. They can be used to separate, isolate, filter and protect.

Examples:

- Certificates of Analysis and a Certificate of Conformance can be used to satisfy qualification and/or acceptance activities (e.g. receiving inspection) by customers.

- Get faster customer service by having a single employee customer service agent so the customer deals only with single agent.

Your comprehensive package for learning and training the TRIZ problem solving methodology. Includes mobile app, books, PowerPoints and real world examples.

31. Porous Materials

The inventive principle ‘Porous Materials’ refers to making an object or system porous or adding porous elements. If already porous, use the pores to introduce a useful function into the organization. Porous materials allow some substances to pass through and block others. Use this property for separating and filtering out desired or undesirable elements, information, etc.

Example:

- Use a receiving inspection to filter incoming materials

- Use final inspection to prevent a faulty product from reaching customers

- Form a committee to filter ideas worth implementing according to design and technology strategy, etc.

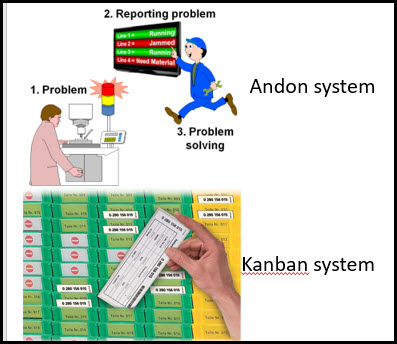

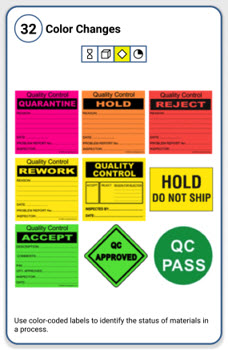

32. Color Changes

In quality management, use color or change of color to attract attention status changes that need instant action, i.e. Andon system, Kanban, etc.

References

Northrop Grumman, Defensive Systems Division - Rolling Meadows, IL Operator Self-Inspection and Product Assessment Program, http://www.bmpcoe.org/bestpractices/internal/ngdsd/ngdsd_44.html

Gennady Retseptor, 40 Inventive Principles in Quality Management, http://www.realinnovation.com/archives/2003/03/a/01.pdf

Darrell Mann, Hands –On Systematic Innovation for Business and Management, IFR Press 2009, ISBN1-898546-73-8

Article written by Andrej Trebar of CREATIV PLUS D.O.O V for Quality Assurance Solutions. Article edited and posted by Quality Assurance Solutions

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |